Abstract

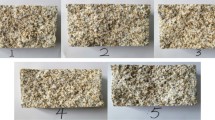

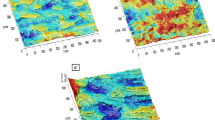

The peak shear displacement (PSD) of artificial joints was studied by the shear test of cement mortar duplicate joints under constant normal load. First, the splitting rock joints were produced by the Brazilian splitting method, and the high-precision point cloud of joint surface morphology was acquired by three-dimensional (3D) scanning method. The polylactic acid (PLA) base mold was produced by 3D printing technology. The duplicate joints with the same joint surface as the splitting rock joints were obtained by pouring cement mortar on the PLA base mold. Then, shear tests of 20 cement mortar specimens with 5 groups of joint surface morphologies under 4 different normal loads were carried out, and the joint shear stress-displacement curves were obtained. The influencing factors of the PSD were studied. The results indicate that the PSD is inversely related to the joint roughness and positively related to the normal stress (NS). The limitation of Barton’s empirical formula is that it cannot predict (fit) the PSD of the joints with JRC = 0 and reflect the effect of NS on the PSD. To quantitatively study the PSD of joints, an empirical formula that can comprehensively consider the influence of surface roughness and NS is introduced based on the test results. The modified model overcomes the limitation of Barton’s empirical formula which ignored the NS and can well reflect the sensitivity of joint roughness coefficient (JRC) to PSD. The acquisition of PSD can provide a basis for the numerical simulation of rock engineering and provide quantitative research methods for the analysis of stick-slip events.

Similar content being viewed by others

References

Asadollahi P (2009) Stability analysis of a single three dimensional rock block: effect of dilatancy and high-velocity water jet impact. PhD dissertation, University of Texas, Austin

Ban LR, Qi CZ, Lu CS (2018) A direction-dependent shear strength criterion for rock joints with two new roughness parameters. Arab J Geosci 11(16):466

Ban LR, Qi CZ, Chen HX, Yan FY, Ji CM (2019) A new criterion for peak shear strength of rock joints with a 3D roughness parameter. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-019-02007-z

Bandis S (1980) Experimental studies of scale effects on shear strength and deformation of rock joints. PhD dissertation, Leeds university, England

Barton N (1973) Review of a new shear-strength criterion for rock joints. Eng Geol 7(4):287–332

Barton N (1982) Modelling rock joint behavior from in situ block tests: implications for nuclear waste repository design. Office of Nuclear Waste Isolation, Columbus, OH, ONWI-308, pp 96

Barton N, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 10(1–2):1–54

Desai CS, Fishman KL (1991) Plasticity-based constitutive model with associated testing for joints. Int J Rock Mech Min Sci Geomech Abstr 28(1):15–26

Dieterich JH (1972) Time-dependent friction in rocks. J Geophys Res 77(20):3690–3697

Dieterich JH (1978) Time-dependent friction and the mechanics of stick-slip. Pure Appl Geophys 116(4–5):790–806

Fereshtenejad S, Song JJ (2016) Fundamental study on applicability of powder-based 3D printer for physical modeling in rock mechanics. Rock Mech Rock Eng 49(6):2065–2074

Grasselli G (2001) Shear strength of rock joints based on quantified surface description. PhD dissertation, Swiss Federal Institute of Technology, Switzerland

Grasselli G, Egger P (2003) Constitutive law for the shear strength of rock joints based on three-dimensional surface parameters. Int J Rock Mech Min Sci 40(1):25–40

Jiang Q, Feng X, Gong Y, Song L, Ran S, Cui J (2016) Reverse modeling of natural rock joints using 3D scanning and 3D printing. Comput Geotech 73:210–220

Liu P, Ju Y, Ranjith PG, Zheng Z, Wang L, Wanniarachchi A (2016) Visual representation and characterization of three-dimensional hydrofracturing cracks within heterogeneous rock through 3D printing and transparent models. Int J Coal Sci Technol 3(3):284–294

Liu Q, Tian Y, Ji P et al (2018) Experimental investigation of the peak shear strength criterion based on three-dimensional surface description. Rock Mech Rock Eng 51(4):1 005–1 025

Lu BH, Li DC, Tian XY (2015) Development trends in additive manufacturing and 3D printing. Engineering 1(1):85–89

Maerz NH, Franklin JA, Bennett CP (1990) Joint roughness measurement using shadow profilometry. Int J Rock Mech Min Sci Geomech Abstr 27:329–343

Meng FZ, Louis NYW, Zhou H, Wang Z (2018) Comparative study on dynamic shear behavior and failure mechanism of two types of granite joint. Eng Geol 245:356–369

Patton FD (1966) Multiple modes of shear failure in rock. In Proc First Congress of Int Soc Rock Mech, Lisbon, Portugal, pp 509–513

Rodriguez CE, Bommer JJ, Chandler RJ (1999) Earthquake-induced landslides: 1980–1997. Soil Dyn Earthq Eng 18(5):325–346

Singh HK, Basu A (2016) Shear behaviors of ‘real’ natural un-matching joints of granite with equivalent joint roughness coefficients. Eng Geol 211:120–134

Stead D, Wolter A (2015) A critical review of rock slope failure mechanisms: the importance of structural geology. J Struct Geol 74:1–23

Tang ZC, Jiao YY (2019) Choosing appropriate appraisal to describe peak spatial features of rock joint profiles. Int J Geomech. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001641

Tang ZC, Wong NYL (2016) New criterion for evaluating the peak shear strength of rock joints under different contact states. Rock Mech Rock Eng 49(4):1191–1199

Tang ZC, Huang RQ, Liu QS, Wong NYL (2016a) Effect of contact state on the shear behavior of artificial rock joint. Bull Eng Geol Environ 75(2):761–769

Tang ZC, Wong NYL, Jiao YY, Wang XC (2016b) Choosing appropriate parameters for developing empirical shear strength criterion of rock joint: review and new insights. Rock Mech Rock Eng 49(11):4479–4490

Tatone BSA, Grasselli G (2009) A method to evaluate the three dimensional roughness of fracture surfaces in brittle geomaterials. Rev Sci Instrum 80(12):125110–121-10

Tian W, Han N (2017) Preliminary research on mechanical properties of 3D printed rock structures. Geotech Test J 40(3):483–493

Tian YC, Liu QS, Ma H, Liu Q, Deng PH (2018) New peak shear strength model for cement filled rock joints. Eng Geol 233:269–280

Tse R, Cruden DM (1979) Estimating joint roughness coefficients. Int J Rock Mech Min Sci Geomech Abstr 16(5):303–307

Vásárhelyi B (1998) Influence of normal load on joint dilatation rate. Rock Mech Rock Eng 31(2):117–123

Wang WL, Wang TT, Su JJ, Lin CH, Seng CR, Huang TH (2001) Assessment of damage in mountain tunnels due to the Taiwan Chi-Chi Earthquake. Tunn Undergr Space Technol 16(3):133–150

Wibowo J, Amadei B, Sture S, Robertson AB, Price RH (1993) Effect of boundary conditions on the strength and deformability of replicas of natural fractures in welded tuff: comparison between predicted and observed behavior. Sandia Rept 92–2247

Xia CC, Tang ZC, Song YL, Liu YM (2011) Analysis of relationship between joint PSD and its influence factors. Rock Soil Mech 32(6):1654–1658 (in Chinese)

Xia CC, Tang ZC, Xiao WM, Song YL (2014) New peak shear strength criterion of rock joints based on quantified surface description. Rock Mech Rock Eng 47(2):387–400

Yang ZY, Lo SC, Di CC (2001) Reassessing the joint roughness coefficient (JRC) estimation using Z2. Rock Mech Rock Eng 34:243–251

Yang J, Rong G, Hou D, Peng J, Zhou CB (2016) Experimental study on peak shear strength criterion for rock joints. Rock Mech Rock Eng 49(3):821–835

Yoshinaka R, Yamabe T (1986) Joint stiffness and the deformation behavior of discontinuous rock. Int J Rock Mech Min Sci Geomech Abstr 23(1):19–28

Funding

This study is supported by the National Key R&D Programs of China (No. 802015CB575), National Natural Science Foundation of China (Nos. 51478027, 51174012, 41502323), and Beijing Postdoctoral Research Foundation.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ban, L., Gao, A., Qi, C. et al. A modified model for estimating peak shear displacement of artificial joints. Bull Eng Geol Environ 79, 5585–5597 (2020). https://doi.org/10.1007/s10064-020-01912-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-020-01912-w