Abstract

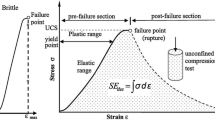

One of the most important parameters to predict the cost and time of tunnel excavation is the penetration rate of the tunnel boring machine (TBM). This is because the advance rate of the TBM is highly dependent on this parameter and is directly related to the cost and time of tunnel excavation. There are several methods to estimate advance rate, including experimental, empirical and analytical methods. In this study, based on the actual collected data from the Amirkabir Water Conveyance Tunnel in Iran, a new empirical method to predict the TBM penetration rate using the drop modulus and the equivalent thrust per cutter is proposed. The drop modulus is defined as the slope of the post-failure stage of the stress–strain curve of the rock mass, and the equivalent thrust per cutter is an important operational parameter of the TBM. The results show that there is a direct relation between the TBM penetration rate and the equivalent thrust per cutter, and an inverse relation between the TBM penetration rate and the drop modulus, and, finally, a power equation is proposed to predict the TBM penetration rate using both parameters. It is emphasized that the TBM penetration rate is a function of both parameters.

Similar content being viewed by others

References

Alber M (1996) Prediction of penetration and utilization for hard rock TBMs. In: Barla M (ed) Prediction and performance in rock. Mech. and Rock Eng. Torino, vol. 2. Balkema, Rotterdam, pp 721–725

Alejano LR, Rodriguez-Dono A, Alonso E, Fdez-Manin G (2009) Ground reaction curves for tunnels excavated in different quality rock masses showing several types of post-failure behavior. Tunn Undergr sp tech 24(6):689–705

Alejano LR, Alonso E, Rodriguez-Dono A, Fernandez-Manin G (2010) Application of the convergence-confinement method to tunnels in rock masses exhibiting Hoek–Brown strain-softening behaviour. Int J Rock Mech Min Sci 47(1):150–160

Barton N (1999) TBM performance estimation in rock using QTBM. Tunnels & Tunnelling International, pp 30–34

Barton N (2000) TBM tunnelling in jointed and faulted rock. Balkema, Brookfield 173

Cai M, Kaiser PK, Uno H, Tasaka Y, Minami M (2004) Estimation of rock mass deformation modulus and strength of jointed rock masses using the GSI system. Int J Rock Mech Min Sci 41(1):3–19

Cai M, Kaiser PK, Tasakab Y, Minami M (2007) Determination of residual strength parameters of jointed rock masses using the GSI system. Int J Rock Mech Min Sci 44(2):247–265

Egger P (2000) Design and construction aspects of deep tunnels (with particular emphasis on strain softening rocks). Tunn Undergr Sp Tech 15(4):403–408

Farmer IW, Glossop NH (1980) Mechanics of disc cutter penetration. Tunnels and Tunneling 12(6):22–25

Gong QM, Zhao J (2007) Influence of rock brittleness on TBM penetration rate in Singapore granite. Tunn Undergr Sp Tech 22(3):317–324

Graham PC (1976) Rock exploration for machine manufacturers. In: Bieniawski ZT (ed) Exploration for rock engineering. Balkema, Rotterdam, pp 173–180

Hassanpour J, Rostami J, Zhao J (2011) A new hard rock TBM performance prediction model for project planning. Tunnell Undergr Space Technol 26(5):595–603

Hoek E, Brown ET (1997) Practical estimates of rock mass strength. Int J Rock Mech Sci Geom Abstr 34(8):1165–1186

Hoek E, Carranza-Torres C, Corkum B (2002) Hoek–Brown failure criterion–2002 edition. In: Proceedings of the North American Rock Mechanics Symposium (NARMS-TAC 2002). Mining Innovation and Technology, Toronto, pp 267–273

Hoek E, Diederichs MS (2006) Empirical estimation of rock mass modulus. Int J Rock Mech Min Sci 43(2):203–215

Hoek E, Carranza-Torres C, Diederichs MS, Corkum B (2008) Kersten Lecture: Integration of geotechnical and structural design in tunneling. Proceedings University of Minnesota 56th Annual Geotechnical Engineering Conference. Minneapolis, 29 February 2008, pp 1–53

Khademi Hamidi J, Shahriar K, Rezai B, Rostami J (2011) Response by the authors to S. Yagiz discussion to the paper: J. Khademi Hamidi et al. (2010). Performance prediction of hard rock TBM using rock mass rating (RMR) system, Tunneling and underground space technology. 25: 333-345. Tunn Undergr Sp Tech 26(6):795–797

Khademi Hamidi J, Shahriar K, Rezai B, Rostami J (2010) Performance prediction of hard rock TBM using rock mass rating (RMR) system. Tunn Undergr Sp Tech 25(4):333–345

Lo KY, Lee CF (1973) Stress analysis and slope stability in strain-softening material. Geotechnique 23:1–11

Ma H, Yin L, Ji H (2011) Numerical study of the effect of confining stress on rock fragmentation by TBM cutters. Int J Rock Mech Min Sci 48:1021–1033

Mansouri M, Moomivand H (2010) Influence of rock mass properties on TBM penetration rate in Karaj- Tehran water conveyance tunnel. J Geol Min Res 2(5):114–121

Marinos P, Hoek E (2000) GSI: a geologically friendly tool for rock mass strength estimation. In: Proceedings of the GeoEng2000 at the international conference on geotechnical and geological engineering, Melbourne, Techonomic publishers, Lancaster, pp 1422–1446

Medel-Morales RC, Botello-Rionda S (2013) Design and optimization of tunnel boring machines by simulating the cutting rock process using the discrete element method. Computación y Sistemas 17(3):329–339

Nelson P, O’Rourke TD (1983) Tunnel boring machine performance in sedimentary rocks. Report to Goldberg-Zoino Associates of New York, P.C., by School of Civil and Environmental of Civil Engineering. Cornell University. Geotechnical Engineering Report 83–3. Ithaca. New York, 438

Palmström A (1995) RMi- a rock mass characterization system for rock engineering purposes. chapter7, PhD thesis, Oslo University, Norway

Rocscience, Roclab (2002) Rocscience inc., Toronto, Canada

Rummel F, Fairhurst C (1970) Determination of the post-failure behavior of brittle rock using a servo-controlled testing machine. Rock Mech 2:189–204

SCE (2009) to (2011) Engineering Geology Asbuilt Maps and Site Reports of Conveyance Tunnel (Lot 2), SCE, Seeber G (1999) Druckstollen und Druckschächte. Enke, Stuttgart

Soleiman Dehkordi M, Lazemi HA, Shahriar K, Soleiman Dehkordi M (2015a) Estimation of the Rock Load in Non-squeezing Ground Condition Using the Post Failure Properties of Rock. Mass, Geotechnical and Geological Engineering 33(4):1115–1128

Soleiman Dehkordi M, Lazemi HA, Shahriar K (2015b) Application of the strain energy ratio and the equivalent thrust per cutter to predict the penetration rate of TBM, case study: Karaj - Tehran water conveyance tunnel of Iran. Arab J Geosci 8(7):4833–4842

Soleiman Dehkordi M, Shahriar K, Maarefvand P, Gharouninik M (2013) Application of the strain energy to estimate the rock load in squeezing ground condition of Emamzade Hashem tunnel in Iran. Arab J Geosci 6(4):1241–1248

Soleiman Dehkordi M, Shahriar K, Maarefvand P, Gharouninik M (2011) Application of the strain energy to estimate the rock load in non-squeezing ground condition. Arch Min Sci 56(3):551–566

Tarkoy PJ (1987) Practical geotechnical and engineering properties for tunnel-boring machine performance analysis and prediction transportation research record 1087. Transportation Research Board. National Research Council, pp 62–78

Wang S, Zheng H, Li C, Ge X (2011) A finite element implementation of strain-softening rock mass. Int J Rock Mech Mining Sci 48:67–76

Yagiz S, Karahan H (2011) Prediction of hard rock TBM penetration rate using particle swarm optimization. Int J Rock Mech Min Sci 48:427–433

Yagiz S (2006) A model for the prediction of tunnel boring machine performance. IAEG2006 paper number 383. Proceedings of the 10th IAEG international congress, Nottingham, UK, 6-10 September 2006

Zheng H, Liu DF, Lee CF, Ge XR (2005) Principle of analysis of brittle-plastic rock mass. Int J Solids Struct 42:139–158

Acknowledgements

The authors are indebted to the staff composed of consulting engineers, contractors and employers for offering data to us, and to all people who helped us during the preparation of this paper. The authors are also indebted to reviewers, whose comments hopefully lead to a more accurate estimation of TBM ROP.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lazemi, H.A., Soleiman Dehkordi, M. Estimation of the TBM penetration rate using the post-failure behavior of a rock mass and the equivalent thrust per cutter. A case study: the Amirkabir Water Transferring Tunnel of Iran. Bull Eng Geol Environ 78, 1735–1746 (2019). https://doi.org/10.1007/s10064-017-1205-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-017-1205-2