Abstract

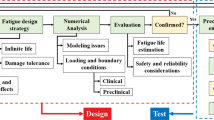

Artificial joints are exposed to loads on a daily basis. Loads on the bone through the artificial joint and the joint’s sliding surface shear force may cause implant fixation failure, fatigue fractures, wear of the bearing and foreign body reactions. Artificial joints can experience sudden internal damage, which can be fatal if it occurs during activities performed at high altitudes or in water. The standard design hip prosthesis has a metal femoral stem. Most stem fractures are caused at the proximal one third of the stem by fatigue due to repetitive loading. Femoral stem neck fractures can also occur. To eliminate in vivo prosthesis failures, safety performance preclinical studies evaluate stem body and neck breakage. However, the development of new femoral stems via prototyping and fatigue test verification would require excessive time and money. Therefore, evaluation methods based on numerical analyses, such as finite element analysis (FEA), have been introduced to simulate tests on actual machines. Fatigue strength design verification using FEA can efficiently identify a design that can pass International Organization for Standardization fatigue tests. FEA may also aid with composite implant development by enabling efficient preclinical testing to prove safety using minimal actual fatigue testing. Once a biological safety study of a composite material is performed, a clinical trial can prove its clinical efficacy and safety and device regulatory approval can be requested. This review was created based on a translation of the Japanese review written in the Japanese Journal of Artificial Organs in 2020 (Vol. 49, No. 3, pp. 195–198), with adding some additional contents and references.

Similar content being viewed by others

References

Rostoker W, Chao EY, Galante JO. Defects in failed stems of hip prostheses. J Biomed Mater Res. 1978;12:635–51.

Wroblewski BM. The mechanism of fracture of the femoral prosthesis in total hip replacement. Int Orthop. 1979;3:137–9.

Marmor L, Gruen TA. Stem fractures of extra-heavy Cobra femoral hip prostheses. Report of two cases. Clin Orthop Relat Res. 1984;190:148–53.

Chao EY, Coventry MB. Fracture of the femoral component after total hip replacement. An analysis of fifty-eight cases. J Bone Jt Surg Am. 1981;63:1078–94.

Pazzaglia UE, Ghisellini F, Barbieri D, Ceciliani L. Failure of the stem in total hip replacement. A study of aetiology and mechanism of failure in 13 cases. Arch Orthop Trauma Surg. 1988;107:195–202.

Woolson ST, Milbauer JP, Bobyn JD, Yue S, Maloney WJ. Fatigue fracture of a forged cobalt-chromium-molybdenum femoral component inserted with a report of ten cases. J Bone Jt Surg Am. 1997;79:1842–8.

Buttaro M, Comba F, Zanotti G, Piccaluga F. Fracture of the C-stem cemented femoral component in revision hip surgery using bone impaction grafting. Hip Int. 2015;25:184–7.

ISO 7206/3. Determination of endurance properties of stemmed femoral components without application of torsion, implants for surgery—partial and total hip joint prostheses. Geneva: International Standards Organisation; 1987.

ISO 7206/4. Determination of endurance properties of stemmed femoral components with application of torsion. Implants for surgery—partial and total hip joint prostheses. Geneva: International Standards Organization; 1989.

Rand J, Chao E. Femoral implant neck fracture following total hip arthroplasty: a report of three cases. Clin Orthop Relat Res. 1987;221:255–9.

Gilbert J, Buckley C, Jacobs J, Bertin KC, Zernich MR. Intergranular corrosion-fatigue failure of cobalt-alloy femoral stems: a failure analysis of. J Bone Jt Surg Am. 1994;76:110–5.

ISO 7206/6. Determination of endurance properties of head and neck region of stemmed femoral components. Partial and total hip joint prostheses. Geneva: International Standards Organization; 1992.

Raimondi MT, Pietrabissa R. Modelling evaluation of the testing condition influence on the maximum stress induced in a hip prosthesis during ISO 7206 fatigue testing. Med Eng Phys. 1999;21:353–9.

Pharmaceutical and Food Safety Bureau, no. 0306001: March 6, 2009. Guidelines for review of artificial hip joints. https://www.std.pmda.go.jp/stdDB/Data/MDStd/AppStd/3000001_01_2009.pdf.

FDA. Reporting of computational modeling studies in medical device submissions in food and drug administration. Silver Spring, MD: Food and Drug Administration; 2016. https://www.fda.gov/media/87586/download.

Lee EW, Kim HT. Early fatigue failures of cemented, forged, cobalt-chromium femoral stems at the neck-shoulder junction. J Arthroplasty. 2001;16:236–8.

Yoshimoto K, Nakashima Y, Nakamura A, Mawatari T, Todo M, Hara D, Iwamoto Y. Neck fracture of femoral stems with a sharp slot at the neck: biomechanical. J Orthop Sci. 2015;20:881–7.

Dargahi J, Najarian S, Amiri S. Optimization of the geometry of total knee implant in the sagittal plane using FEA. Biomed Mater Eng. 2003;13:439–49.

Ahir SP, Blunn GW, Haider H, Walker PS. Evaluation of a testing method for the fatigue performance of total knee tibial trays. J Biomech. 1999;32:1049–57.

Sabesan VJ, Lima DJL, Whaley JD, Pathak V, Zhang L. The effect of glenohumeral radial mismatch on different augmented total shoulder arthroplasty glenoid designs: a finite element analysis. J Shoulder Elbow Surg. 2019;28:1146–53.

Nakahara I, Takao M, Bandoh S, Bertollo N, Walsh WR, Sugano N. In vivo implant fixation of carbon fiber-reinforced PEEK hip prostheses in an ovine. J Orthop Res. 2013;31:485–92.

Takashima K, Nakahara I, Uemura K, Hamada H, Ando W, Takao M, Sugano N. Clinical outcomes of proximal femoral fractures treated with a novel carbon. Clinical outcomes of proximal femoral fractures treated with a novel carbon fiber-reinforced polyetheretherketone intramedullary nail. Injury. 2020;51:678–82.

Takashima K, Nakahara I, Hamada H, Ando W, Takao M, Uemura K, Sugano N. A carbon fiber-reinforced polyetheretherketone intramedullary nail improves fracture site visibility on postoperative radiographic images. Injury. 2021;52:2225–32.

Piccioli A, Piana R, Lisanti M, Di Martino A, Rossi B, Camnasio F, Gatti M, Maniscalco P, Gherlinzoni F, Spinelli MS, Donati DM, Biagini R, Capanna R, Denaro V, Italian Orthopaedic Society (SIOT) Bone Metastasis Study Group. Carbon-fiber reinforced intramedullary nailing in musculoskeletal tumor surgery: a national multicentric experience of the Italian Orthopaedic Society (SIOT) Bone Metastasis Study Group. Injury. 2017;48:S55–9.

Lerch M, Kurtz A, Stukenborg-Colsman C, Nolte I, Weigel N, Bouguecha A, Behrens BA. Bone remodeling after total hip arthroplasty with a short stemmed metaphyseal loading implant: finite element analysis validated by a prospective DEXA investigation. J Orthop Res. 2012;30:1822–9.

Carli AV, Negus JJ, Haddad FS. Periprosthetic femoral fractures and trying to avoid them: what is the contribution of femoral component design to the increased risk of periprosthetic femoral fracture? Bone Jt J. 2017;99-B:50–9.

Pétursson Þ, Edmunds KJ, Gíslason MK, Magnússon B, Magnúsdóttir G, Halldórsson G, Jónsson H Jr, Gargiulo P. Bone mineral density and fracture risk assessment to optimize prosthesis selection in total hip replacement. Comput Math Methods Med. 2015;2015: 162481.

Greenhill DA, Abbasi P, Darvish K, Star AM. Broach handle design changes force distribution in the femur during total hip arthroplasty. J Arthroplasty. 2017;32:2017–22.

Acknowledgements

This work was supported by JSPS KAKENHI (Grant number: 19H01176).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sugano, N., Hamada, H., Uemura, K. et al. Numerical analysis evaluation of artificial joints. J Artif Organs 25, 185–190 (2022). https://doi.org/10.1007/s10047-022-01345-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10047-022-01345-0