Abstract

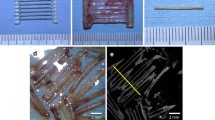

Small-diameter biotube vascular grafts developed by in-body tissue architecture had high patency at implantation into rabbit carotid arteries or rat abdominal aortas. However, the thin walls (34 ± 14 μm) of the original biotubes made their implantation difficult into areas with low blood flow volumes or low blood pressure due to insufficient mechanical strength to maintain luminal shape. In this study, caged molds with several windows were designed to prepare more robust biotubes. The molds were assembled with silicone tubes (external diameter 2 mm) and cylindrical covers (outer diameter 7 mm) with 12 linear windows (1 × 9 mm). After the molds were embedded into beagle dorsal subcutaneous pouches for 4 weeks, type C (cage) biotubes were obtained by completely extracting the surrounding connective tissues from the molds and removing the molds. The biotube walls (778 ± 31 μm) were formed at the aperture (width 1 mm) between the silicone rods and the covers by connective cell migration through the windows of the covers. Excellent mechanical properties (external pressure resistance, approximately 4 times higher than beagle native femoral arteries; burst strength, approximately 2 times higher than original biotubes) were obtained. In the acute phase of implantation of the biotubes into beagle femoral arteries, perfect patency was obtained with little stenosis and no aneurysmal dilation. The type C biotubes may be useful for implantation into peripheral arteries or veins in addition to aortas.

Similar content being viewed by others

References

Esquivel CO, Blaisdell FW. Why small vascular grafts fail: a review of clinical and experimental experience and the significance of the interaction of blood at the interface. J Surg Res. 1986;41:1–15.

Watanabe T, Kanda K, Yamanami M, Ishibashi-Ueda H, Yaku H, Nakayama Y. Long-term animal implantation study of biotube-autologous small-caliber vascular graft fabricated by in-body tissue architecture. J Biomed Mater Res B Appl Biomater. 2011;98:120–6.

Yamanami M, Ishibashi-Ueda H, Yamamoto A, Iida H, Watanabe T, Kanda K, Yaku H, Nakyama Y. Implantation study of small-caliber “biotube” vascular grafts in a rat model. J Artif Organs. 2013;16:59–65.

Sakai O, Kanda K, Takamizawa K, Sato T, Yaku H, Nakayama Y. Faster and stronger vascular “Biotube” graft fabrication in vivo using a novel nicotine-containing mold. J Biomed Mater Res B Appl Biomater. 2009;90:412–20.

Nakayama Y, Tsujinaka T. Acceleration of robust “biotube” vascular graft fabrication by in-body tissue architecture technology using novel eosin Y-releasing mold. J Biomed Mater Res B Appl Biomater. 2014;102:231–8.

Sakai O, Kanda K, Ishibashi-Ueda H, Takamizawa K, Ametani A, Yaku H, Nakayama Y. Development of the wing-attached rod for acceleration of “Biotube” vascular grafts fabrication in vivo. J Biomed Mater Res B Appl Biomater. 2007;83:240–7.

Oie T, Yamanami M, Ishibahi-Ueda H, Kanda K, Yaku H, Nakayama Y. In-body optical stimulation formed connective tissue vascular grafts, “biotubes”, with many capillaries and elastic fibers. J Artif Organs. 2010;13:235–40.

Hayashi K, Handa H, Nagasawa S, Okumura A, Moritake K. Stiffness and elastic behavior of human intracranial and extracranial arteries. J Biomech. 1980;13:175–84.

Hayashi K, Nakamura T. Material test system for the evaluation of mechanical properties of biomaterials. J Biomed Mater Res. 1985;19:133–44.

Hayashi K, Igarashi Y, Takamizawa K. Mechanical properties and hemodynamics in coronary arteries. In: Kitamura K, Abe H, Sagawa K, editors. New approaches in cardiac mechanics. Tokyo: Japan Scientific Societies Press; 1986. p. 285–94.

Nakayama Y, Takewa Y, Sumikura H, Yamnami M, Matui Y, Oie T, Kishimoto Y, Arakawa M, Ohmura K, Kajikawa T, Kanda K, Tatsumi E. In-body tissue-engineered aortic valve (Biovalve type VII) architecture based on 3D printer molding. J Biomed Mater Res B Appl Biomater. 2015;103:1–11.

Funayama M, Takewa Y, Oie T, Matsui Y, Tatsumi E, Nakayama Y. In situ observation and enhancement of leaflet tissue formation in bioprosthetic “biovalve”. J Artif Organs. 2015;18:40–7.

Madras PN, Ward CA, Johnson WR, Singh PI. Anastomotic hyperplasia. Surgery. 1981;90:922–3.

Watanabe T, Kanda K, Ishibashi-Ueda H, Yaku H, Nakayama Y. Autologous small-caliber “biotube” vascular grafts with argatroban loading: a histomorphological examination after implantation to rabbits. J Biomed Mater Res B Appl Biomater. 2010;92:236–42.

Klinkert P, van Dijk PJ, Breslau PJ. Polytetrafluoroethylene femorotibial bypass grafting: 5-year patency and limb salvage. Ann Vasc Surg. 2003;17:486–91.

Arena FJ. Arterial kink and damage in normal segments of the superficial femoral and popliteal arteries abutting nitinol stents-a common cause of late occlusion and restenosis? A single-center experience. J Invasive Cardiol. 2005;17:482–6.

Campbell GR, Campbell JH. Development of tissue engineered vascular grafts. Curr Pharm Biotechnol. 2007;8:43–50.

Acknowledgments

The authors thank Ms. Mami Sone for her participation in this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Furukoshi, M., Moriwaki, T. & Nakayama, Y. Development of an in vivo tissue-engineered vascular graft with designed wall thickness (biotube type C) based on a novel caged mold. J Artif Organs 19, 54–61 (2016). https://doi.org/10.1007/s10047-015-0859-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10047-015-0859-4