Abstract

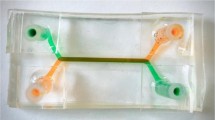

Rectangular microchannels 50 μm high and 30, 40, 50, 60, or 70 μm wide were fabricated by adjusting the width of a gap cut in a polyethylene sheet 50 μm thick and sandwiching the sheet between an acrylic plate and a glass plate. Flux in the microchannels was measured under three different inner surface conditions: uncoated, albumin-coated, and confluent growth of rat fibroblasts on the bottom of the microchannels. The normalized flux in microchannels with cultured fibroblasts or albumin coating was significantly larger than that in the uncoated channels. The experimental data for all microchannels deviated from that predicted by classical hydrodynamic theory. At small aspect ratio the flux in the microchannels was larger than that predicted theoretically, whereas it became smaller at large aspect ratio. The aspect ratio rather than Reynolds number is the correct property for predicting the variation of the normalized friction factor. We postulate that two counteracting effects, rotation of large molecules and slip velocity at the corners of the microchannels, are responsible for the deviation. From these results we conclude that albumin coating should be carried out in the same way as when fabricating our integrating cell-culture system. The outcomes of this study are not only important for the design of our culture system, but also quite informative for general microfluidics.

Similar content being viewed by others

References

Khandurina J, Guttman A. Bioanalysis in microfluidic devices. J Chromatogr A. 2002;943:159–83.

Heller M, Guttman A. Integrated microfabricated biodevices. New York: Marcel Dekker; 2001.

Gad-el-Hak M, editor. The MEMS handbook. 2nd ed. Boca Raton: CRC Press; 2005.

Jayaraj S, Kanga S, Suh YK. A review on the analysis and experiment of fluid flow and mixing in micro-channels. J Mech Sci Technol. 2007;21:536–48.

Shoffner MA, Cheng J, Hvichia GE, Kricka LJ, Wilding P. Chip PCR. I. Surface passivation of microfabricated silicon-glass chips for PCR. Nucleic Acids Res. 1996;24:375–9.

Cheng J, Shoffner MA, Hvichia GE, Kricka LJ, Wilding P. Chip PCR. II. Investigation of different PCR amplification systems in microfabricated silicon-glass chips. Nucleic Acids Res. 1996;24:380–5.

Korin N, Bransky A, Dinnar U, Levenberg S. Periodic “flow-stop” perfusion microchannel bioreactors for mammalian and human embryonic stem cell long-term culture. Biomed Microdevices. 2009;11:87–94.

Walker GM, Ozers MS, Beebe DJ. Cell infection within a microfluidic device using virus gradients. Sens Actuators B. 2004;98:347–55.

Voldman J, Gray ML, Schmidt MA. Microfabrication in biology and medicine. Ann Rev Biomed Eng. 1999;1:401–25.

Kaihara S, Borenstein J, Koka R, Lalan S, Ochoa ER, Ravens M, Pien H, Cunningham B, Vacanti JP. Silicon micromachining to tissue engineer branched vascular channels for liver fabrication. Tissue Eng. 2000;6:105–17.

White FM. Viscous fluid flow. 2nd ed. McGraw–Hill, Inc., New York; 1991.

Papautsky I, Brazzle J, Ameel T, Frazier AB. Laminar fluid behavior in microchannels using micropolar fluid theory. Sens Actuators. 1999;73:101–8.

Steinke ME, Kandlikar SG. Single-phase liquid friction factors in microchannels. Int J Therm Sci. 2006;45:1073–83.

Hetsroni G, Mosyak A, Pogrebnyak E, Yarin LP. Fluid flow in micro-channels. Int J Heat Mass Transf. 2005;48:1982–98.

Ye S, Zhu K, Wang W. Laminar flow of micropolar fluid in rectangular microchannels. Acta Mech Sin. 2006;22:403–8.

Saha AA, Mitra SK. Effect of dynamic contact angle in a volume of fluid (VOF) model for a microfluidic capillary flow. J Colloid Interface Sci. 2009;339:461–80.

Liu CF, Ni YS. The fractal roughness effect of micro Poiseuille flows using the lattice Boltzmann method. Int J Eng Sci. 2009;47:660–8.

Rosengarten G, Cooper-White J, Metcalfe G. Experimental and analytical study of the effect of contact angle on liquid convective heat transfer in microchannels. Int J Heat Mass Transf. 2006;49:4161–70.

Khadem MH, Shams M, Hossainpour S. Numerical simulation of roughness effects on flow and heat transfer in microchannels at slip flow regime. Int Commun Heat Mass Trans. 2009;36:69–77.

Chen CH. Slip-flow heat transfer in a microchannel with viscous dissipation. Heat Mass Trans. 2006;42:853–60.

Patzek TW, Silin DB. Shape factor and hydraulic conductance in noncircular capillaries. J Colloid Interface Sci. 2001;236:295–304.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, Z., Fukuda, S., Yokoyama, M. et al. Flux characteristics of cell culture medium in rectangular microchannels. J Artif Organs 14, 238–244 (2011). https://doi.org/10.1007/s10047-011-0564-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10047-011-0564-x