Abstract

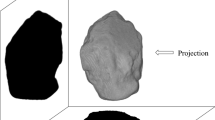

This study aims to suggest a new method for predicting 3D sphericity through traditional 2D image processing through a novel sieving analysis. The 3D sphericity indices of grains (over 3000 particles for each material) from seven irregular granular materials are determined using μCT slices. These indices are then compared with existing 2D indices obtained through SEM image processing. Additionally, seven synthetic materials (semi-regular in size and shape) are also assessed to account for unusual particle shapes. The findings shed light on the role of sphericity in the rate at which particles pass through sieve openings. The results indicate that the initial passing rate of grains is strongly correlated with the 3D sphericity indices, which significantly decrease as sphericity decreases. The proposed method involves a sequential sieving test, performed similarly to the conventional sieving test but conducted sequentially at different time steps. Several correlations between 3D sphericity and its 2D counterparts are presented, which can successfully predict the 3D sphericity indices. Additionally, two empirical equations are proposed to predict the most frequent flatness and elongation aspect ratios, used in the Zingg diagram. Furthermore, the grading analysis derived from both 2D and 3D image processing is compared with sieve analysis. The results show that, unlike the 2D results, the grading curves obtained from 3D image processing are in excellent agreement with the sieve analysis. A corrected grading curve, derived from traditional 2D image processing, is proposed to align with 3D grading curves.

Similar content being viewed by others

References

Krumbein, W.C.: Measurement and geological significance of shape and roundness of sedimentary particles. J. Sediment. Res. 11, 64–72 (1941). https://doi.org/10.1306/D42690F3-2B26-11D7-8648000102C1865D

Tunwal, M., Mulchrone, K.F., Meere, P.A.: Quantitative characterization of grain shape: Implications for textural maturity analysis and discrimination between depositional environments. Sedimentology 65, 1761–1776 (2018). https://doi.org/10.1111/sed.12445

Mitchell, J.K., Soga, K.: others: Fundamentals of soil behavior. Wiley, New York (2005)

Cho, G.-C., Dodds, J., Santamarina, J.C.: Particle shape effects on packing density, stiffness, and strength: natural and crushed sands. J. Geotech. Geoenviron. Eng. 132, 591–602 (2006). https://doi.org/10.1061/(asce)1090-0241(2006)132:5(591)

Rousé, P.C., Fannin, R.J., Shuttle, D.A.: Influence of roundness on the void ratio and strength of uniform sand. Géotechnique. 58, 227–231 (2008). https://doi.org/10.1680/geot.2008.58.3.227

Peña, A.A., García-Rojo, R., Herrmann, H.J.: Influence of particle shape on sheared dense granular media. Granul. Matter 9, 279–291 (2007). https://doi.org/10.1007/s10035-007-0038-2

Kandasami, R.K., Murthy, T.G.: Manifestation of particle morphology on the mechanical behaviour of granular ensembles Manifestation of particle morphology on the mechanical. Granul. Matter (2017). https://doi.org/10.1007/s10035-017-0703-z

Falagush, O., McDowell, G.R., Yu, H.S.: Discrete element modeling of cone penetration tests incorporating particle shape and crushing. Int. J. Geomech. 15, 4015003 (2015). https://doi.org/10.1061/(ASCE)GM.1943-5622.0000463

Zhou, B., Huang, R., Wang, H., Wang, J.: DEM investigation of particle anti-rotation effects on the micromechanical response of granular materials. Granul. Matter 15, 315–326 (2013). https://doi.org/10.1007/s10035-013-0409-9

Ferellec, J.-F., McDowell, G.R.: A method to model realistic particle shape and inertia in DEM. Granul. Matter 12, 459–467 (2010). https://doi.org/10.1007/s10035-010-0205-8

Azéma, E., Radjai, F., Saussine, G.: Quasistatic rheology, force transmission and fabric properties of a packing of irregular polyhedral particles. Mech. Mater. 41, 729–741 (2009). https://doi.org/10.1016/j.mechmat.2009.01.021

Azéma, E., Radjaï, F., Radjai, F.: Stress-strain behavior and geometrical properties of packings of elongated particles. Phys. Rev. E 81, 51304 (2010). https://doi.org/10.1103/PhysRevE.81.051304

Cleary, P.W., Sawley, M.L.: DEM modelling of industrial granular flows: 3D case studies and the effect of particle shape on hopper discharge. Appl. Math. Model. 26, 89–111 (2002). https://doi.org/10.1016/S0307-904X(01)00050-6

Delaney, G.W., Cleary, P.W.: Fundamental relations between particle shape and the properties of granular packings. AIP Conf. Proc. 1145, 837–840 (2009). https://doi.org/10.1063/1.3180058

Yan, B., Regueiro, R.A.: Three-dimensional discrete element method parallel computation of Cauchy stress distribution over granular materials. Int. J. Numer. Anal. Methods Geomech. 43, 974–1004 (2019). https://doi.org/10.1002/nag.2917

Wadell, H.: Sphericity and roundness of rock particles. J. Geol. (1933). https://doi.org/10.1086/624040

Krumbein, W.C., Sloss, L.L.: Stratigraphy and sedimentation. LWW (1951)

Zingg, T.: Beitrag zur schotteranalyse, (1935)

Angelidakis, V., Nadimi, S., Utili, S.: Elongation, flatness and compactness indices to characterise particle form. Powder Technol. 396, 689–695 (2022). https://doi.org/10.1016/j.powtec.2021.11.027

Mora, C.F., Kwan, A.K.H.: Sphericity, shape factor, and convexity measurement of coarse aggregate for concrete using digital image processing. Cem. Concr. Res. 30, 351–358 (2000). https://doi.org/10.1016/S0008-8846(99)00259-8

Sukumaran, B., Ashmawy, A.K.: Quantitative characterisation of the geometry of discret particles. Géotechnique. 51, 619–627 (2001). https://doi.org/10.1680/geot.2001.51.7.619

Altuhafi, F., O’Sullivan, C., Cavarretta, I.: Analysis of an image-based method to quantify the size and shape of sand particles. J. Geotech. Geoenviron. Eng. 139, 1290–1307 (2013). https://doi.org/10.1061/(asce)gt.1943-5606.0000855

Fonseca, J., O’Sullivan, C., Coop, M.R., Lee, P.D.: Non-invasive characterization of particle morphology of natural sands. Soils Found. 52, 712–722 (2012). https://doi.org/10.1016/j.sandf.2012.07.011

Alshibli, K.A., Druckrey, A.M., Al-Raoush, R.I., Weiskittel, T., Lavrik, N.V.: Quantifying morphology of sands using 3D imaging. J. Mater. Civ. Eng. 27, 04014275 (2015). https://doi.org/10.1061/(asce)mt.1943-5533.0001246

Zhao, B., Wang, J.: 3D quantitative shape analysis on form, roundness, and compactness with μ CT. Powder Technol. 291, 262–275 (2016). https://doi.org/10.1016/j.powtec.2015.12.029

Field, D.A.: Laplacian smoothing and Delaunay triangulations. Commun. Appl. Numer. Methods. 4, 709–712 (1988). https://doi.org/10.1002/cnm.1630040603

Kobbelt, L.P., Botsch, M., Schwanecke, U., Seidel, H.-P.: Feature sensitive surface extraction from volume data. In: Proceedings of the 28th annual conference on computer graphics and interactive techniques. pp. 57–66. Association for Computing Machinery, New York, NY, USA (2001)

Ventola, A., Dolling, R., Hryciw, R.D.: Image analysis and hardware developments for the vision cone penetrometer (VisCPT). In: Geo-Congress 2020. pp. 640–648 (2020)

Wadell, H.: Volume, shape, and roundness of rock particles. J. Geol. 40, 443–451 (1932)

Santamarina, J.C., Cho, G.C.: Soil behaviour: the role of particle shape. In: Advances in geotechnical engineering: the skempton conference: proceedings of a three day conference on advances in geotechnical engiineering organised by the Institution of Civil Engineers. pp 604–617 (2004)

Rodriguez, J.M., Johansson, J.M.A., Edeskär, T.: Particle shape determination by two-dimensional image analysis in geotechnical engineering. In: Nordic geotechnical meeting (NGM2012). pp. 207–218. Danish geotechnical society, Copenhagen, Denmark (2012)

Zheng, W., Hu, X., Tannant, D.D.: Shape characterization of fragmented sand grains via X-ray computed tomography imaging. Int. J. Geomech. 20, 04020003 (2020). https://doi.org/10.1061/(asce)gm.1943-5622.0001599

Fakharian, K., Kaviani-Hamedani, F., Sooraki, A., Amindehghan, M., Lashkari, A.: Continuous bidirectional shear moduli monitoring and micro X-ray CT to evaluate fabric evolution under different stress paths. Granul. Matter 25, 52 (2023). https://doi.org/10.1007/s10035-023-01339-6

Lashkari, A., Karimi, A., Fakharian, K., Kaviani-Hamedani, F.: Prediction of undrained behavior of isotropically and anisotropically consolidated firoozkuh sand: Instability and flow liquefaction. Int. J. Geomech. 17, 1–17 (2017). https://doi.org/10.1061/(ASCE)GM.1943-5622.0000958

Ahmadinezhad, A., Jafarzadeh, F., Sadeghi, H.: Combination of water head control and axis translation techniques in new unsaturated cyclic simple shear tests. Soil Dyn. Earthq. Eng. 126, 105818 (2019). https://doi.org/10.1016/j.soildyn.2019.105818

Fakharian, K., Kaviani-Hamedani, F., Imam, S.M.R.: Influences of initial anisotropy and principal stress rotation on the undrained monotonic behavior of a loose silica sand. Can. Geotech. J. (2021). https://doi.org/10.1139/cgj-2020-0791

Shabani, F., Kaviani-Hamedani, F.: Cyclic response of sandy subsoil layer under traffic-induced principal stress rotations: application of bidirectional simple shear apparatus. Soil Dyn. Earthq. Eng. 164, 107573 (2023)

Kaviani-Hamedani, F., Fakharian, K., Lashkari, A.: Bidirectional shear wave velocity measurements to track fabric anisotropy evolution of a crushed silica sand during shearing. Int. J. Geoenviron. Geotech. Eng. (2021). https://doi.org/10.1061/(ASCE)GT.1943-5606.0002622

Vafaei, N., Fakharian, K., Sadrekarimi, A.: Sand-sand and sand-steel interface grain-scale behavior under shearing. Transp. Geotech. 30, 100636 (2021). https://doi.org/10.1016/j.trgeo.2021.100636

Fakharian, K., Vafaei, N.: Effect of density on skin friction response of piles embedded in sand by simple shear interface tests. Can. Geotech. J. (2020)

Fakharian, K., Hamedani, F.K., Parandian, I., Aghdam, M.J.: Investigation of fabric evolution using bidirectional shear wave velocity measurements. In: 7th international symposium on deformation characteristics of geomaterials (IS-Glasgow 2019). p. 3008 (2019)

Fakharian, K., Kaviani-Hamedani, F., Sooraki, A., Amindehghan, M.: A new fabric evolution monitoring method using continuous bidirectional shear wave velocity measurements in sand. In: Proceedings of the 20th international conference on soil mechanics and geotechnical engineering, Sydney 2022, Sydney (2022)

Ahmadinezhad, A., Jafarzadeh, F., Shahbodagh, B., Hosseinpour, S., Khorami, S.: Development of a dynamic hollow cylinder apparatus for investigating the cyclic response of unsaturated soils subjected to stress anisotropy. Transp. Geotech. 40, 100968 (2023). https://doi.org/10.1016/j.trgeo.2023.100968

Zheng, W., Tannant, D.: Frac sand crushing characteristics and morphology changes under high compressive stress and implications for sand pack permeability. Can. Geotech. J. 53, 1412–1423 (2016)

ISO, D.I.N.: ISO 9276-6:2008 Representation of results of particle size analysis—part 1: graphical representation, 1st

Wei, L.M., Yang, J.: On the role of grain shape in static liquefaction of sand–fines mixtures. Géotechnique. 64, 740–745 (2014). https://doi.org/10.1680/geot.14.T.013

Xiao, Y., Long, L., Matthew Evans, T., Zhou, H., Liu, H., Stuedlein, A.W.: Effect of particle shape on stress-dilatancy responses of medium-dense sands. J. Geotech. Geoenviron. Eng. 145, 1–15 (2019). https://doi.org/10.1061/(asce)gt.1943-5606.0001994

Yang, J., Luo, X.D.: Exploring the relationship between critical state and particle shape for granular materials. J. Mech. Phys. Solids 84, 196–213 (2015). https://doi.org/10.1016/j.jmps.2015.08.001

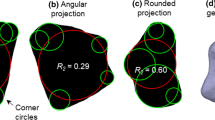

Zheng, J., Hryciw, R.D.: Traditional soil particle sphericity, roundness and surface roughness by computational geometry. Geotechnique 65, 494–506 (2015). https://doi.org/10.1680/geot.14.P.192

Phansalkar, N., More, S., Sabale, A., Joshi, M.: Adaptive local thresholding for detection of nuclei in diversity stained cytology images. Int. Conf. Commun. Signal Process. (2011). https://doi.org/10.1109/ICCSP.2011.5739305

Jang, D.-J., Frost, J.D., Park, J.-Y.: Preparation of epoxy impregnated sand coupons for image analysis. Geotech. Test. J. 22, 153–164 (1999). https://doi.org/10.1520/GTJ11274J

Chen, Y.H., Tong, X.: Application of the DEM to screening process: a 3D simulation. Min. Sci. Technol. 19, 493–497 (2009). https://doi.org/10.1016/S1674-5264(09)60092-2

Dong, K.J., Wang, B., Yu, A.B.: Modeling of particle flow and sieving behavior on a vibrating screen: from discrete particle simulation to process performance prediction. Ind. Eng. Chem. Res. 52, 11333–11343 (2013). https://doi.org/10.1021/ie3034637

Liu, Y., Zhou, X., You, Z., Ma, B., Gong, F.: Determining aggregate grain size using discrete-element models of sieve analysis. Int. J. Geomech. 19, 1–10 (2019). https://doi.org/10.1061/(asce)gm.1943-5622.0001376

Abbireddy, C.O.R., Clayton, C.R.I.: A review of modern particle sizing methods. Proc. Inst. Civ. Eng. Geotech. Eng. 162, 193–201 (2009). https://doi.org/10.1680/geng.2009.162.4.193

Acknowledgements

The authors would like to acknowledge the contributions of Behin Negareh Co. for their sincere cooperation in selecting effective protocols for Micro CT Tomography. Special thanks to Mr. Amin Shahrokhi and Morteza Abbasi for their joint endeavors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaviani-Hamedani, F., Esmailzade, M., Adineh, K. et al. Quantifying three-dimensional sphericity indices of irregular fine particles from 2D images through sequential sieving tests. Granular Matter 26, 13 (2024). https://doi.org/10.1007/s10035-023-01376-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-023-01376-1