Abstract

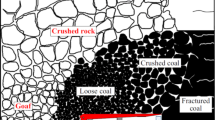

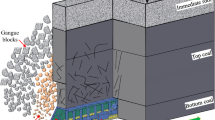

Dynamic sublevel caving technology (DSCT) proposed by the researchers is one of effective methods to solve the problems of low top coal recovery, poor drawing balance and support stability in longwall top coal caving (LTCC) with large dip angle. To investigate the reasonable number of supports in a sublevel (N) and the top coal drawing mechanisms under DSCT, this research takes Panel 7401 in Zouzhuang Coal Mine as the geological background. Firstly, the optimal threshold value of N is theoretically analyzed, and the numerical simulations of drawing experiments under different Ns are calculated. The results show that when N = 3, the top coal recovery is the highest, the number of excessive drawing top coal at the upper end is relatively small, and the drawing balance is great, which is conducive to improving the resource recovery and safety management. With increasing N, the over-development of right top coal boundary towards the upper end increases, the range of coal ridge in the lower sublevel also gradually increases, while the strong force chain area at the upper end gradually decreases, resulting in the support stability becoming worse. In addition, the displacement of top coal at the upper end gradually increases with increasing N, and the permanent loss feature of residual top coal exists in the upper sublevel. The field top coal recovery under DSCT was measured finally, obtaining that DSCT can improve the top coal recovery by about 5% and promote the stability and working efficiency of the support. The research results have great theoretical and guiding significance for the high yield and high efficiency LTCC technology for thick coal seam with large dip angle.

Graphical Abstract

Similar content being viewed by others

References

Wang, G.F.: Development of fully mechanized top coal caving technology and new hydraulic support for top coal caving. J. Min. Strata Control Eng. 4, 18–20 (1996)

Gao, Y.J.: Design and stress analysis of hydraulic support with high drawing opening. China Coal 9, 33–35 (2004)

Fu, Q., Yan, S.H., Wu, J.: Theoretical research on loose top-coal drawing of longwall sublevel caving mining. Chin. J. Rock Mech. Eng. 4, 568–572 (2002)

Yang, S.L., Wei, W.J., Zhang, J.W.: Top coal movement law of dynamic group caving method in LTCC with an inclined seam. Mining, Metall. & Explor. 37, 1545–1555 (2020)

Wang, J.C., Wei, W.J., Zhang, J.W.: Theoretical description of drawing body shape in an inclined seam with longwall top coal caving mining. Int. J. Coal Sci. Technol. 7, 182–195 (2020)

Wang, J.C., Wei, W.J., Zhang, J.W., et al.: Stability analysis of support around the longwall top-coal caving mining in steeply thick coal seam. J. China Coal Soc. 42, 2783–2791 (2017)

Çelik, A., Özçelik, Y.: Investigation of the efficiency of longwall top coal caving method applied by forming a face in horizontal thickness of the seam in steeply inclined thick coal seams by using a physical model. Int. J. Rock Mech. Min. Sci. 148, 104917 (2021)

Wu, J.: Theory and practice of sub-level caving method in China. J. China Coal Soc. 16, 1–11 (1991)

Wu, J., Zhang, Y.: Study on the basic theory of longwall top-coal caving system. J. China Univ. Min. Technol. 27, 332–335 (1998)

Wang, J.C., Fu, Q.: The loose medium flow field theory and its application on the longwall top-coal caving. J. China Coal Soc. 27, 337–341 (2002)

Wang, J.: Engineering practice and theoretical progress of top-coal caving mining technology in China. J. China Coal Soc. 43, 43–51 (2018)

Wang, J.C., Zhang, J.W.: BBR study of top-coal drawing law in longwall top-coal caving mining. J. China Coal Soc. 40, 487–493 (2015)

Zhang, J.W., Cheng, D.L., Yang, Y.C., et al.: Numerical and theoretical investigations of the effect of the gangue-coal density ratio on the drawing mechanism in longwall top-coal caving. Int. J. Coal Sci. Technol. 9, 31 (2022).

Zhang, J.W., Wang, J.C., Wei, W.J.: Effect of face dip angle on the drawing mechanism in longwall top-coal caving mining. J. China Unversity Min. Technol. 47, 805–814 (2018)

Zhu, D.J., Chen, Z.H., Du, W.S., et al.: Caving mechanisms of loose top-coal in longwall top-coal caving mining based on stochastic medium theory. Arab. J. Geosci. 11, 621 (2018)

Yu, B., Zhu, D., Chen, Z.: Top-coal drawing law of LTCC mining based on stochastic medium theory. J. China Coal Soc. 42, 1366–1371 (2017)

Wang, Z.H., Wang, J.C., Yang, S.L.: An ultrasonic-based method for longwall top-coal cavability assessment. Int. J. Rock Mech. Min. Sci. 112, 209–225 (2018)

Le, T.D., Zhang, C.G., Oh, J., et al.: A new cavability assessment for longwall top coal caving from discontinuum numerical analysis. Int. J. Rock Mech. Min. Sci. 115, 11–20 (2019)

Alehossein, H., Poulsen, B.A.: Stress analysis of longwall top coal caving. Int. J. Rock Mech. Min. Sci. 47, 30–41 (2010)

Khanal, M., Adhikary, D., Balusu, R.: Evaluation of mine scale longwall top coal caving parameters using continuum analysis. Min. Sci. Technol. (China) 21, 787–796 (2011)

Khanal, M., Adhikary, D., Balusu, R.: Prefeasibility study-Geotechnical studies for introducing longwall top coal caving in Indian mines. J. Min. Sci. 50, 719–732 (2014)

Klishin, V.I., Fryanov, V.N., Pavlova, L.D., et al.: Modeling top coal disintegration in thick seams in longwall top coal caving. J. Min. Sci. 55, 247–256 (2019)

Wei, W.J., Yang, S.L., Li, M., et al.: Motion mechanisms for top coal and gangue sizes in longwall top coal caving (LTCC) with an extra-thick seam. Rock Mech. Rock Eng. 55, 5107–5121 (2022)

Wei, W.J., Wang, J.C., Zhang, J.W., et al.: Drawing mechanisms of granular top coal considering the structure of hydraulic support in longwall top coal caving. Bull. Eng. Geol. Environ. 82, 138 (2023)

Wang, J.C., Wei, W.J., Zhang, J.W.: Effect of the size distribution of granular top coal on the drawing mechanism in LTCC. Granular Matter 21, 70 (2019)

Wang, J.C., Wei, W.J., Zhang, J.W., et al.: Numerical investigation on the caving mechanism with different standard deviations of top coal block size in LTCC. Int. J. Min. Sci. Technol. 30, 583–591 (2020)

Wang, J.C., Yang, S.L., Wei, W.J., et al.: Drawing mechanisms for top coal in longwall top coal caving (LTCC): A review of two decades of literature. Int. J. Coal Sci. Technol. 8, 1171–1196 (2021)

Jangara, H., Ozturk, C.A.: Longwall top coal caving design for thick coal seam in very poor strength surrounding strata. Int. J. Coal Sci. Technol. 8, 641–658 (2021)

Le, T.D., Oh, J., Hebblewhite, B., et al.: A discontinuum modelling approach for investigation of longwall top coal caving mechanisms. Int. J. Rock Mech. Min. Sci. 106, 84–95 (2018)

Le, T.D., Bui, X.N.: Effect of key parameters on top coal first caving and roof first weighting in longwall top coal caving: A case study. Int. J. Geomech. 20, 04020037 (2020)

Unver, B., Yasitli, N.E.: Modelling of strata movement with a special reference to caving mechanism in thick seam coal mining. Int. J. Coal Geol. 66, 227–252 (2006)

Song, Z.Y., Konietzky, H.: A particle-based numerical investigation on longwall top coal caving mining. Arab. J. Geosci. 12, 556 (2019)

Zhang, Q.L., Yue, J.C., Liu, C., et al.: Study of automated top-coal caving in extra-thick coal seams using the continuum-discontinuum element method. Int. J. Rock Mech. Min. Sci. 122, 104033 (2019)

Zhang, Q.L., Yuan, R.F., Wang, S., et al.: Optimizing simulation and analysis of automated top-coal drawing technique in extra-thick coal seams. Energies 13, 232 (2020)

Wang, J.C., Liu, F., Zhang, J.W.: Investigation on the propagation mechanism of explosion stress wave in underground mining. Geomach. Eng. 17, 297–307 (2019)

Yasitli, N.E., Unver, B.: 3D numerical modeling of longwall mining with top-coal caving. Int. J. Rock Mech. Min. Sci. 42, 219–235 (2005)

Wang, J.C., Wei, W.J., Zhang, J.W., et al.: Laboratory and field validation of a LTCC recovery prediction model using relative size of the top coal blocks. Bull. Eng. Geol. Environ. 80, 1389–1401 (2020)

Ghosh, A.K., Gong, Y.: Improving coal recovery from longwall top coal caving. J. Mines Met. Fuels 62, 51–57 (2014)

Song, Z.Y., Konietzky, H., Herbst, M.: Drawing mechanism of fractured top coal in longwall top coal caving. Int. J. Rock Mech. Min. Sci. 130, 104329 (2020)

Wei, W.J., Song, Z.Y., Zhang, J.W.: Theoretical equation of initial top-coal boundary in longwall top-coal caving mining. Intern. J. Min. Miner. Eng. 9, 157–176 (2018)

Yang, L., Li, L.H., Wei, W.J.: Optimization of caving technology in an extrathick seam with longwall top coal caving mining. Adv. Mater. Sci. Eng. 2021, 7725159 (2021)

Yang, S.L., Zhang, J.W., Chen, Y., et al.: Effect of upward angle on the drawing mechanism in longwall top-coal caving mining. Int. J. Rock Mech. Min. Sci. 85, 92–101 (2016)

Wang, J.C., Zhang, J.W., Li, Z.L.: A new research system for caving mechanism analysis and its application to sublevel top-coal caving mining. Int. J. Rock Mech. Min. Sci. 88, 273–285 (2016)

Wang, J.C., Zhao, B.W., Zhao, P.F., et al.: Research on the longwall top-coal caving mining technique in extremely inclined and soft thick coal seam. J. China Coal Soc. 42, 286–292 (2017)

Wang, J.C., Chen, Y., Zhang, J.W.: Optimization study on drawing technique of longwall top coal caving in extrathick coal seam based on BBR system. Coal Eng. 48, 1–4 (2016)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant no. 52204163), the National Key R&D Program of China (Grant no. 2022YFC2904001), the Young Elite Scientists Sponsorship Program by CAST (Grant no. 2022QNRC001), the Beijing Natural Science Foundation (Grant no. 2232059), the Fundamental Research Funds for the Central Universities (Grant no. 2023JCCXNY04), and the Open Fund of Key Laboratory of Safety and High-efficiency Coal Mining, Ministry of Education (Grant no. JYBSYS2021204).

Author information

Authors and Affiliations

Contributions

WW: Conceptualization, methodology, writing-original draft preparation. PW: methodology, writing-reviewing and editing. ZJ: Supervision, Conceptualization, ZZ: Investigation, data curation. YL: Data curation. ZX: Supervision, writing-reviewing and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors know that there is no conflict of interest concerning the publication of this technical note.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Weijie, W., Weidong, P., Jinwang, Z. et al. Dynamic sublevel caving technology for thick seams with large dip angle in longwall top coal caving (LTCC). Granular Matter 25, 56 (2023). https://doi.org/10.1007/s10035-023-01351-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-023-01351-w