Abstract

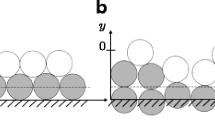

The present work aims at two main objectives: validation of former equations developed for predicting the discharge flow of particles from silos but, in this case, for flat (oblate) lentil grains, and characterization of the kinematics of those grains at the outlet of the silo for both mass and funnel flow regimes. Special emphasis is placed in describing the way in which the flat grains arrange in their way out of the silo opening. This is presented through a spatiotemporal analysis of the particles at the outlet of the hopper. Results demonstrated that, although the collective behavior of the flow can be represented by those theoretical approaches, the vertical velocity distributions during mass flow regime are incorrectly described by a continuum perspective and have to be revised. On the other hand, the parabolic vault hypothesis seems to be still adequate for describing the velocity profile in the funnel flow regime.

Graphical abstract

Similar content being viewed by others

References

Job, N., Dardenne, A., Pirard, J.-P.: Silo flow-pattern diagnosis using the tracer method. J. Food Eng. 91, 118–125 (2009)

Fitzpatrick, J.J., Iqbal, T., Delaney, C., Twomey, T., Keogh, M.K.: Effect of powder properties and storage conditions on the flowability of milk powders with different fat contents. J. Food Eng. 64, 435–444 (2004)

Fürll, C., Hoffmann, T.: The influence of the granulometric condition on the flow characteristics of shredded grain products in their dependence on the duration of storage. Powder Technol. 235, 307–311 (2013)

Mankoc, C., Janda, A., Arévalo, R., Pastor, J.M., Zuriguel, I., Garcimartín, A., Maza, D.: The flow rate of granular materials through an orifice. Granular Matter 9, 407–414 (2007)

Anand, A., Curtis, J.S., Wassgren, C.R., Hancock, B.C., Ketterhagen, W.R.: Predicting discharge dynamics from a rectangular hopper using the discrete element method (DEM). Chem. Engn. Sci. 63, 5821–5830 (2008)

Wu, J., Binbo, J., Chen, J., Yang, Y.: Multi-scale study of particle flow in silos. Adv. Pow. Tech. 20, 62–73 (2009)

González-Montellano, C., Ramírez, A., Gallego, E., Ayuga, F.: Validation and experimental calibration of 3D discrete element models for the simulation of the discharge flow in silos. Chem. Engn. Sci. 66, 5116–5126 (2011)

Uñac, R.O., Benegas, O.A., Vidales, A.M., Ippolito, I.: Experimental study of discharge rate fluctuations in a silo with different hopper geometries. Powder Technol. 225, 214–220 (2012)

Bhateja, A.: Velocity scaling in the region of orifice influence in silo draining under gravity. Phys. Rev. E 102, 042904 (2020)

Beverloo, W.A., Leniger, H.A., van de Velde, J.: The flow of granular solids through orifices. Chem. Eng. Sci 15, 260–269 (1961)

Brown, R.L., Richards, J.C.: Principles of Powder Mechanics, 1st edn. Pergamon Press, Oxford (1970)

Carleton, A.J.: The effect of fluid-drag forces on the discharge of free-falling solids from hoppers. Powder Technol. 6, 91–96 (1972)

Oldal, I., Keppler, I., Csizmadia, B., Fenyvesi, L.: Outflow properties of silos: the effect of arching. Adv. Powder Technol. 23, 290–297 (2012)

Vivanco, F., Rica, S., Melo, F.: Dynamical arching in a two dimensional granular flow. Granular Matt. 14, 563–576 (2012)

Liu, S.D., Zhou, Z.Y., Zou, R.P., Pinson, D., Yu, A.B.: Flow characteristics and discharge rate of ellipsoidal particles in a flat bottom hopper. Powder Technol. 253, 70–79 (2014)

Calderón, C.A., Villagrán Olivares, M.C., Uñac, R.O., Vidales, A.M.: Correlations between flow rate parameters and the shape of the grains in a silo discharge. Powder Technol. 320, 43–50 (2017)

Mellmann, J., Hoffmann, T., Fürll, C.: Mass flow during unloading of agricultural bulk materials from silos depending on particle form, flow properties and geometry of the discharge opening. Powder Technol. 253, 46–52 (2014)

Börzsönyi, T., Somfai, E., Szabó, B., Wegner, S., Mier, P., Rose, G., Stannarius, R.: Packing, alignment and flow of shape-anisotropic grains in a 3D silo experiment. New J. Phys. 18, 093017 (2016)

Golshan, S., Esgandari, B., Zarghami, R., Blais, B., Saleh, K.: Experimental and DEM studies of velocity profiles and residence time distribution of non-spherical particles in silos. Powder Technol. 373, 510–521 (2020)

Darias, J.R., Gella, D., Fernandez, M.E., Zuriguel, I., Maza, D.: The hopper angle role on the velocity and solid-fraction profiles at the outlet of silos. Powder Technol. 366, 488–496 (2020)

Villagrán Olivares, M.C., Benito, J.G., Uñac, R.O., Vidales, A.M.: Towards a one parameter equation for a silo discharging model with inclined outlets. Powder Technol. 336, 265–272 (2018)

Nedderman, R.M., Tüzün, U., Savage, S.B., Houlsby, G.T.: The flow of granular materials—I. Discharge rates from hoppers. Chem. Eng. Sci. 37, 1597–1609 (1982)

Hu, G., Lin, P., Zhang, Y., Li, L., Yang, L., Chen, X.: Size scaling relation of velocity field in granular flows and the Beverloo law. Granular Matter 21, 21 (2019)

Tran-Cong, S., Gay, M., Michaelides, E.E.: Drag coefficients of irregularly shaped particles. Powder Technol. 139, 21–32 (2004)

Rubio-Largo, S.M., Janda, A., Maza, D., Zuriguel, I., Hidalgo, R.C.: Disentangling the free-fall arch paradox in silo discharge. Phys. Rev. Lett. 114, 238002 (2015)

Acknowledgements

This work was supported by Universidad Nacional de San Luis under grant 03-2718 and by CONICET (PIP 11220170100245).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that there is no conflict of interests regarding the publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Escudero Acuña, F.G., Villagrán Olivares, M.C., Benito, J.G. et al. Kinematics of the discharge of flat particles from model silos. Granular Matter 24, 102 (2022). https://doi.org/10.1007/s10035-022-01265-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-022-01265-z