Abstract

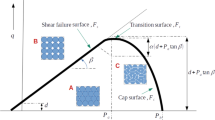

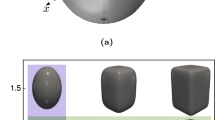

Packed structures are an essential part of nuclear reactors, food, chemical, transport, and process industries. Since the safety and quality of products in the packed structures is of high priority, identifying critical failure spots in packed structures is of utmost importance. The present study aims to identify critical spots in the hexagonally packed structures under mechanical loads in the presence of defects. The role of defects in the formation of force networks is also investigated in this work. The granular mechanics approach is used to analyze the analogous force pattern formation in packed structures. Discrete element method (DEM) is used to simulate the particle interaction in the granular assembly. The hexagonal packing, in X-Y plane, is created by stacking the horizontal contacting particle chains in X-direction, and thus creating inclined contact chains in the Y-direction. Hexagonal packings display two stable force network formations corresponding to compression along X and Y-direction. The effect of point defect and stacking fault on the force network is investigated. The presence of point defect is shown to induce high force concentration near the defect zone. When the assembly is compressed along X-direction, force redistribution at the defect zone increases the force levels in inclined force chains. When the assembly is compressed along Y-direction, the point defect induces zones with lesser force levels. Further, the study explores various levels of force zones induced in the system. The effect of the presence of multiple point defects in the system is analyzed further. The distance between two point defects and their loading direction induces a different set of force chains. Stacking fault is found to induce strong vertical force chains at the defect zone, unlike point defect. However, multiple stacking faults affect only the horizontal force chains near the defect zone. The present study highlights the formation of critical spots as well as lower force zones and also provides useful insights to design efficient packing structures.

Graphical Abstract

Similar content being viewed by others

References

Van Antwerpen, W., Du Toit, C.G., Rousseau, P.G.: A review of correlations to model the packing structure and effective thermal conductivity in packed beds of mono-sized spherical particles. Nucl. Eng. Des. 240(7), 1803–1818 (2010)

Zhang, C.S., Ying, A., Abdou, M.A., Park, Y.-H.: Ceramic breeder pebble bed packing stability under cyclic loads. Fusion Eng. Des. 109, 267–271 (2016)

Gong, B., Cheng, H., Feng, Y., Luo, X., Wang, L., Wang, X.: Effect of pebble size distribution and wall effect on inner packing structure and contact force distribution in tritium breeder pebble bed. Energies 14(2), 449 (2021)

Gazetas, G., Apostolou, M.: Nonlinear soil–structure interaction: foundation uplifting and soil yielding. In: Proceedings Third UJNR Workshop on Soil-Structure Interaction, pp. 29–30 (2004)

Ahmed, M., Mohamed, M.H., Mallick, J., Hasan, M.A., et al.: 3d-analysis of soil-foundation-structure interaction in layered soil. Open J. Civ. Eng. 4(04), 373 (2014)

Hadzalic, E., Ibrahimbegovic, A., Dolarevic, S.: Failure mechanisms in coupled soil-foundation systems. Coupled Syst. Mech. 7, 27–42 (2018)

Aste, T., Di Matteo, T., Galleani d’Agliano, E.: Stress transmission in granular matter. J. Phys.: Condens. Matter 14(9), 2391 (2002)

Campbell, C.S.: A problem related to the stability of force chains. Granul. Matter 5(3), 129–134 (2003)

Vijayan, A., Annabattula, R.K.: Semi-analytical framework for stress-conductivity correlations in periodic granular assemblies under compaction. Int. J. Adv. Eng. Sci. Appl. Math. (2021). https://doi.org/10.1007/s12572-021-00294-w

Vijayan, A., Gan, Y., Annabattula, R.K.: Evolution of fabric in spherical granular assemblies under the influence of various loading conditions through dem. Granul. Matter 22(2), 1–15 (2020)

Paternoster, A., Van Camp, J., Vanlanduit, S., Weeren, A., Springael, J., Braet, J.: The performance of beer packaging: Vibration damping and thermal insulation. Food Packag. Shelf Life 11, 91–97 (2017)

Ortiz, C., Blasco, J., Balasch, S., Torregrosa, A.: Shock absorbing surfaces for collecting fruit during the mechanical harvesting of citrus. Biosys. Eng. 110(1), 2–9 (2011)

Ma, S., Karkee, M., Han, F., Sun, D., Zhang, Q.: Effect of air pressure and shaking frequency on fruit damage in mechanical harvesting of apples. In: 2017 ASABE Annual International Meeting, page 1. American Society of Agricultural and Biological Engineers (2017)

Wang, W., Huazhong, L., Zhang, S., Yang, Z.: Damage caused by multiple impacts of litchi fruits during vibration harvesting. Comput. Electron. Agric. 162, 732–738 (2019)

Desmet, M., Lammertyn, J., Scheerlinck, N., Verlinden, B.E., Nicolaı, B.M.: Determination of puncture injury susceptibility of tomatoes. Postharvest Biol. Technol. 27(3), 293–303 (2003)

Komarnicki, P., Stopa, R., Szyjewicz, D., Młotek, M.: Evaluation of bruise resistance of pears to impact load. Postharvest Biol. Technol. 114, 36–44 (2016)

Dalle Donne, M., Günther, E., Schumacher, G., Sordon, G., Vollath, D., Wedemeyer, H., Werle, H.: Research and development work for the lithium orthosilicate pebbles for the karlsruhe ceramic breeder blanket. J. Nucl. Mater. 179, 796–799 (1991)

Zhou, Q., Gao, Y., Liu, K., Xue, L., Yan, Y.: Fabrication of li2tio3 pebbles by a selective laser sintering process. Fusion Eng. Des. 100, 166–170 (2015)

Tan, G., Song, S., Xin, H., Cai, L., Li, Y., Zhang, Y.: Efficient fabrication of high strength li2tio3 ceramic pebbles via improved rolling ball method assisted by sesbania gum binder. Ceram. Int. (2021)

Li, Z.: The effect of compressibility, loading position and probe shape on the rupture probability of tomato fruits. J. Food Eng. 119(3), 471–476 (2013)

Opara, U.L., Pathare, P.B.: Bruise damage measurement and analysis of fresh horticultural produce—a review. Postharvest Biol. Technol. 91, 9–24 (2014)

Li, Z., Li, P., Yang, H., Liu, J.: Internal mechanical damage prediction in tomato compression using multiscale finite element models. J. Food Eng. 116(3), 639–647 (2013)

Allais, I., Alvarez, G.: Analysis of heat transfer during mist chilling of a packed bed of spheres simulating foodstuffs. J. Food Eng. 49(1), 37–47 (2001)

Pathare, P.B., Opara, U.L., Vigneault, C., Delele, M.A., FAl-Said, A.-J.: Design of packaging vents for cooling fresh horticultural produce. Food Bioprocess Technol. 5(6), 2031–2045 (2012)

Van Zeebroeck, M., Tijskens, E., Dintwa, E., Kafashan, J., Loodts, J., De Baerdemaeker, J., Ramon, H.: The discrete element method (dem) to simulate fruit impact damage during transport and handling: Case study of vibration damage during apple bulk transport. Postharvest Biol. Technol. 41(1), 92–100 (2006)

Van Zeebroeck, M., Darius, P., De Ketelaere, B., Ramon, H., Tijskens, E., et al.: The effect of fruit factors on the bruise susceptibility of apples. Postharvest Biol. Technol. 46(1), 10–19 (2007)

Scheffler, O.C., Coetzee, C.J., Opara, U.L.: A discrete element model (dem) for predicting apple damage during handling. Biosys. Eng. 172, 29–48 (2018)

Annabattula, R.K., Gan, Y., Zhao, S., Kamlah, M.: Mechanics of a crushable pebble assembly using discrete element method. J. Nucl. Mater. 430(1–3), 90–95 (2012a)

Annabattula, R.K., Gan, Y., Kamlah, M.: Mechanics of binary and polydisperse spherical pebble assembly. Fusion Eng. Des. 87, 853–858 (2012)

Mitterlehner, T., Kartnig, G., Haider, M.: Analysis of the thermal ratcheting phenomenon in packed-bed thermal energy storage using discrete element method. FME Trans. 48(2), 427–431 (2020)

Yi, C., Liu, Y., Qing-song, M., Qi, Y., et al.: Force transmission in three-dimensional hexagonal-close-packed granular arrays with point defect submitted to a point load. Granular Matter 9(3–4), 195–203 (2007)

Tsoungui, O., Vallet, D., Charmet, J.-C.: Use of contact area trace to study the force distributions inside 2d granular systems. Granular Matter 1(2), 65–69 (1998)

Peters, J.F., Muthuswamy, M., Wibowo, J., Tordesillas, A.: Characterization of force chains in granular material. Phys. Rev. E 72(4), 041307 (2005)

Zadeh, A.A., Barés, J., Brzinski, T.A., Daniels, K.E., Dijksman, J., Docquier, N., Everitt, H.O., Kollmer, J.E., Lantsoght, O., Wang, D., et al.: Enlightening force chains: a review of photoelasticimetry in granular matter. Granular Matter 21(4), 1–12 (2019)

Zhang, L., Jun-Qi, W., Zhang, J.: Force-chain identification in quasi-2d granular systems. In AIP Conference Proceedings 1542, 397–400 (2013)

Iikawa, N., Bandi, M.M., Katsuragi, H.: Force-chain evolution in a two-dimensional granular packing compacted by vertical tappings. Phys. Rev. E 97(3), 032901 (2018)

Seguin, A.: Experimental study of some properties of the strong and weak force networks in a jammed granular medium. Granular Matter 22(2), 1–8 (2020)

Yi C.-H., Mu, Q.-S., Tian-De, M.: Discrete element method simulation on the force chains in the two-dimensional granular system under gravity. ACTA PHYSICA SINICA 58(11), 7750–7755 (2009)

Guo, P.: Critical length of force chains and shear band thickness in dense granular materials. Acta Geotech. 7(1), 41–55 (2012)

Nguyen, T.C., Le, L.M., Ly, H.-B., Le, T.-T.: Numerical investigation of force transmission in granular media using discrete element method. Vietnam J. Mech 42, 153–171 (2020)

Luding, S.: Stress distribution in static two-dimensional granular model media in the absence of friction. Phys. Rev. E 55(4), 4720 (1997)

Yi, C., Liu, Y., Miao, T., Qing-song, M., Qi, Y.: Force transmission in three-dimensional hexagonal-close-packed granular arrays with point defect submitted to a point load. Granular Matter 9(3), 195–203 (2007)

Wensrich, C.M., Kisi, E.H., Luzin, V., Rawson, A., Kirstein, O.: Evolution of a contact force network in a 2d granular assembly: an examination using neutron diffraction. Granular Matter 23(3), 1–7 (2021)

Huntley, J.M.: Vacancy effects on the force distribution in a two-dimensional granular pile. Phys. Rev. E 48(5), 4099 (1993)

Desu, R.K., Moorthy, A., Annabattula, R.K.: Dem simulation of packing mono-sized pebbles into prismatic containers through different filling strategies. Fusion Eng. Des. 127, 259–266 (2018)

Dai, W., Reimann, J., Hanaor, D., Ferrero, C., Gan, Y.: Modes of wall induced granular crystallisation in vibrational packing. Granular Matter 21(2), 1–16 (2019)

Amirifar, R., Dong, K., Zeng, Q., An, X., Aibing, Yu.: Effect of vibration mode on self-assembly of granular spheres under three-dimensional vibration. Powder Technol. 380, 47–58 (2021)

Oda, M.: Initial fabrics and their relations to mechanical properties of granular material. Soils Found. 12(1), 17–36 (1972)

Oda, M.: The mechanism of fabric changes during compressional deformation of sand. Soils Found. 12(2), 1–18 (1972)

Oda, M., Konishi, J., Nemat-Nasser, S.: Some experimentally based fundamental results on the mechanical behaviour of granular materials. Géotechnique 30, 479–495 (1980)

Oda, M., Konishi, J., Nemat-Nasser, S.: Experimental micromechanical evaluation of strength of granular materials: effects of particle rolling. Mech. Mater. 1, 269–283 (1982)

Ken-Ichi, K.: Distribution of directional data and fabric tensors. Int. J. Eng. Sci. 22, 149–164 (1984)

O'Sullivan, C.: Particulate discrete element modelling: a geomechanics perspective. Taylor & Francis (2011)

Cundall, P.A., Strack, O.D.L.: A discrete numerical model for granular assemblies. Géotechnique 29(1), 47–65 (1979)

Kloss, C., Goniva, C., Hager, A., Amberger, S., Pirker, S.: Models , algorithms and validation for opensource DEM and CFD-DE. Progr. Comput. Fluid Dyn. 12, 140–152 (2012)

Banerjee, A., Chanda, A., Das, R.: Historical origin and recent development on normal directional impact models for rigid body contact simulation: a critical review. Arch. Comput. Methods Eng. 24(2), 397–422 (2017)

Langstreth Johnson, K., Johnson, K.L.: Contact mechanics. Cambridge University Press (1987)

Di Renzo, A., Maio, F.P.D.: An improved integral non-linear model for the contact of particles in distinct element simulations. Chem. Eng. Sci. 60(5), 1303–1312 (2005)

Verlet, L.: Computer“ experiments’’ on classical fluids. i. thermodynamical properties of lennard-jones molecules. Phys. Rev. 159(1), 98 (1967)

Swope, W.C., Andersen, H.C., Berens, P.H., Wilson, K.R.: A computer simulation method for the calculation of equilibrium constants for the formation of physical clusters of molecules: Application to small water clusters. J. Chem. Phys. 76(1), 637–649 (1982)

Yi Chen-Hong, M., Qing-Sun, Tian-De, M.: The dem simulation for two-dimensional granular system with point defects. ACTA PHYSICA SINICA 57(6), 3636–3640 (2008)

Spannuth, M.J., Mueggenburg, N.W., Jaeger, H.M., Nagel, S.R.: Stress transmission through three-dimensional granular crystals with stacking faults. Granular Matter 6(4), 215–219 (2004)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Compliance with Ethical Standards

Declaration on conflict of interest: The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vijayan, A., Banerjee, A. & Desu, R.K. Role of packing defects in force networks of hexagonally packed structures using discrete element method. Granular Matter 24, 23 (2022). https://doi.org/10.1007/s10035-021-01185-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-021-01185-4