Abstract

This study experimentally investigates the influences of grain shape and gradation on stress-dilatancy parameters. For this purpose, consolidated-drained triaxial tests are conducted on five different granular materials. Specimens are sheared following two different stress paths; axial compression and lateral extension, in order to monitor the influence of stress path on the investigated problem. For each soil, grain shapes, sizes and stress-dilatancy parameters are experimentally determined. Moreover, available data in literature for other sands are compiled with the data of this study. This allows the investigation of the dependence of stress-dilatancy parameters on gradation and grain shape characteristics. Especially with this study, variations of stress-dilatancy constants with grain characteristics are examined. Statistically significant relationships are obtained for predicting stress-dilatancy parameters as functions of average grain shapes. On the other hand, influences of stress path and gradation on stress-dilatancy response are experimentally considered. Finally, compiled and determined data used in the development of the relationships are provided in the form of tables.

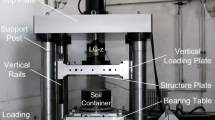

Graphic abstract

Similar content being viewed by others

References

Yasin, S.J.M., Safiullah, A.M.M.: Effect of particle characteristics on the strength and volume change behaviour of sand. J. Civil. Eng. Inst. Eng. Bangladesh CE31(2), 127–148 (2003)

Cho, G.C., Dodds, J., Santamarina, J.C.: Particle shape effects on packing density, stiffness and strength: natural and crushed sands. J. Geotech. Geoenviron. Eng. 132(5), 591–602 (2006). https://doi.org/10.1061/(ASCE)1090-0241(2006)132:5(591)

Cox, M.R.B.: The Influence of Grain Shape on Dilatancy. PhD Thesis, The University of Arizona (2008)

Tsomokos, A., Georgiannou, V.N.: Effect of grain shape and angularity on the undrained response of fine sands. Can. Geotech. J. 47, 539–551 (2010). https://doi.org/10.1139/T09-121

Lim, M.S., Wijeyesekera, D.C., Zainorabidin, A., Bakar, I.: The effects of particle morphology (shapes and sizes) characteristics on its engineering behaviour and sustainable engineering performance of sand. Int. J. Integr. Eng. 4(4), 27–37 (2013)

Abbireddy, C.O.R., Clayton, C.R.I.: The impact of particle form on the packing and shear behaviour of some granular materials: an experimental study. Granular Matter 17(4), 427–438 (2015). https://doi.org/10.1007/s10035-015-0566-0

Altuhafi, F.N., Coop, M.R., Georgiannou, V.N.: Effect of particle shape on the mechanical behavior of natural sands. J. Geotechn. Geoenviron. Eng. 142(12), 04016071 (2016). https://doi.org/10.1061/(ASCE)GT.1943-5606.0001569

Yang, J., Luo, X.D.: The critical state friction angle of granular materials: does it depend on grading? Acta Geotech. 13, 535–547 (2018). https://doi.org/10.1007/s11440-017-0581-x

Li, Y.: Effects of particle shape and size distribution on the shear strength behaviour of composite soils. Bull. Eng. Geol. Env. 72(3–4), 371–381 (2013). https://doi.org/10.1007/s10064-013-0482-7

Pino, L.F.M., Baudet, B.A.: The effect of the particle size distribution on the mechanics of fibre-reinforced sands under one-dimensional compression. Geotext. Geomembr. 43(3), 250–258 (2015). https://doi.org/10.1016/j.geotexmem.2015.02.004

Mahawish, A., Bouazza, A., Gates, W.P.: Effect of particle size distribution on the bio-cementation of coarse aggregates. Acta Geotech. 13, 1019–1025 (2018). https://doi.org/10.1007/s11440-017-0604-7

Xiao, Y., Meng, M., Daouadji, A., Chen, Q., Wu, Z., Jiang, X.: Effects of particle size on crushing and deformation behaviors of rockfill materials. Geosci. Front. 11(2), 375–388 (2020). https://doi.org/10.1016/j.gsf.2018.10.010

Jensen, R.P., Edil, T.B., Bosscher, P.J.: Effect of particle shape on interface behaviour of DEM-simulated granular materials. Int. J. Geomech. 1(1), 1–19 (2001). https://doi.org/10.1080/15323640108500150

Sukumaran, B., Ashmawy, A.K.: Quantitative characterization of the geometry of discrete particles. Geotechnique 51(7), 619–627 (2001)

Ng, T.T.: Behavior of ellipsoids of two sizes. J. Geotech. Geoenviron. Eng. 130(10), 1077–1083 (2004). https://doi.org/10.1061/(ASCE)1090-0241(2004)130:10(1077)

Latha, G.M., Sitharam, T.G.: Effect of particle size and gradation on the behaviour of granular materials simulated using DEM. Ind. Geotech. J. 38(1), 68–88 (2008)

Sazzad, M., Suzuki, K.: A comparison between conventional triaxial and plane-strain compression on a particulate system using 3D DEM. Acta Geotechnica Slovenica 9(2), 17–23 (2012)

Dai, B.B., Yang, J.: Shear strength of assemblies of frictionless particles. Int. J. Geomech. 17(11), 04017102 (2017)

Kandasami, R.K., Murthy, T.G.: Manifestation of particle morphology on the mechanical behaviour of granular ensembles. Granular Matter 19(21), 1–13 (2017). https://doi.org/10.1007/s10035-017-0703-z

Liu, Y., Liu, H., Mao, H.: The influence of rolling resistance on the stress-dilatancy and fabric anisotropy of granular materials. Granular Matter 20(12), 1–16 (2018). https://doi.org/10.1007/s10035-017-0780-z

Zavala, J.M.R.: Importance of the Particle Shape on Mechanical Properties of Soil Materials. PhD Thesis, Lulea University of Technology (2012)

Altuhafi, F., O’Sullivan, C., Cavarretta, I.: Analysis of an image-based method to quantify the size and shape of sand particles. J. Geotech. Geoenviron. Eng. 139(8), 1290–1307 (2013). https://doi.org/10.1061/(ASCE)GT.1943-5606.0000855

Park, J., Santamarina, J.C.: Revised soil classification system for coarse-fine mixtures. J. Geotech. Geoenviron. Eng. 143(8), 04017039 (2017)

Suh, H.S., Kim, K.Y., Lee, L., Yun, T.S.: Quantification of bulk form and angularity of particle with correlation of shear strength and packing density in sands. Eng. Geol. 220, 256–265 (2017). https://doi.org/10.1016/j.enggeo.2017.02.015

Wadell, H.A.: Volume, shape and roundness of rock particles. J. Geol. 40(5), 443–451 (1932)

Rittenhouse, G., Thorp, E.M.: Heavy minerals in sediment-transportation studies. Trans. Am. Geophys. Union 24(2), 524–530 (1943)

Powers, M.C.: A new roundness scale for sedimentary particles. J. Sediment. Res. 23(2), 117–119 (1953)

Krumbein, W., Sloss, L.: Stratigraphy and Sedimentation. WH Freeman and Co., San Francisco (1963)

Alshibli, K.A., Alsaleh, M.I.: Characterizing surface roughness and shape of sands using digital microscopy. J. Comput. Civil Eng. 18(1), 36–45 (2004).

Hassanlourad, M., Salehzadeh, H., Shahnazari, H.: Dilation and particle breakage effects on the shear strength of calcareous sands based on energy aspects. Int. J. Civil Eng. 6(2), 108–119 (2008)

Mesri, G., Vardhanabhuti, B.: Compression of granular materials. Can. Geotech. J. 46, 369–392 (2009)

Alshibli, K.A., Druckrey, A.M., Al-Raoush, R.I., Weiskittel, T., Lavrik, N.V.: Quantifying morphology of sands using 3D imaging. J. Mater. Civ. Eng. 27(10), 04014275 (2015). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001246

Hanaor, D.A.H., Gan, Y., Revay, M., Airey, D.W., Einav, I.: 3D printable geomaterials. Geotechnique 66(4), 323–332 (2016). https://doi.org/10.1680/jgeot.15.P.034

Ouhbi, N., Voivret, C., Perrin, G., Roux, J.N.: 3D particle shape modelling and optimization through proper orthogonal decomposition. Granular Matter 19(86), 1–14 (2017). https://doi.org/10.1007/s10035-017-0771-0

Ghalehjourgh, B.K., Akbulut, S., Celik, S.: Effect of particle roundness and morphology on the shear failure mechanism of granular soil under strip footing. Acta Geotechnica Slovenica 15(1), 43–53 (2018). https://doi.org/10.18690/actageotechslov.15.1.43-53.2018

Frossard, A.: Effect of sand grain shape on interparticle friction; indirect measurements by Rowe’s stress dilatancy theory. Geotechnique 29(3), 341–350 (1979)

Olarte, A.P.: Influence of Particle Shape on the Global Mechanical Response of Granular Packings: Micromechanical Investigation of the Critical State in Soil Mechanics. PhD Thesis, The University of Stuttgart (2008)

Fonseca, J.: The Evolution of Morphology and Fabric of a Sand During Shearing. PhD Thesis, Imperial Collage London (2011)

Yang, J., Wei, L.M.: Collapse of loose sand with the addition of fines: the role of particle shape. Géotechnique 62(12), 1111–1125 (2012). https://doi.org/10.1016/j.sandf.2013.06.009

Dai, B.B., Yang, J., Zhou, C.Y.: Observed effects of interparticle friction and particle size on shear behavior of granular materials. Int. J. Geomech. 16(1), 04015011 (2016). https://doi.org/10.1061/(ASCE)GM.1943-5622.0000520

Mollon, G., Quacquarelli, A., Andò, E., Viggiani, G.: Can friction replace roughness in the numerical simulation of granular materials? Granular Matter 22(42), 1–16 (2020). https://doi.org/10.1007/s10035-020-1004-5

Xiao, Y., Long, L., Evans, T.M., Zhou, H., Liu, H., Stuedlein, A.W.: Effect of particle shape on stress-dilatancy responses of medium-dense sands. J. Geotech. Geoenviron. Eng. 145(2), 04018105 (2019). https://doi.org/10.1061/(ASCE)GT.1943-5606.0001994

Miura, K., Maeda, K., Furukawa, M.: Mechanical characteristics of sands with different primary properties. Soils Found. Jpn. Geotechn. Soc. 38(4), 159–172 (1998)

Herle, I., Gudehus, G.: Determination of parameters of a hypoplastic constitutive model from properties of grain assemblies. Mech. Cohes. Friction. Mater. 4(5), 461–486 (1999)

Cubrinovski, M., Ishihara, K.: Maximum and minimum void ratio characteristics of sands. Soils Found. 42(6), 65–78 (2002)

Rouse, P.C., Fannin, R.J., Shuttle, D.A.: Influence of roundness on the void ratio and strength of uniform sand. Geotechnique 58(3), 227–231 (2008). https://doi.org/10.1680/geot.2008.58.3.227

Zheng, J., Hryciw, R.D.: Index void ratios of sands from their intrinsic properties. J. Geotech. Geoenviron. Eng. 142(12), 06016019 (2016). https://doi.org/10.1061/(ASCE)GT.1943-5606.0001575

Ng, T.T., Ge, L.: Packing void ratios of very dense ternary mixtures of similar ellipsoids. Granular Matter 22(53), 1–13 (2020). https://doi.org/10.1007/s10035-020-01021-1

Santamarina, J.C., Cho, G.C.: Soil behaviour: The role of particle shape. In: Proceedings of the Advances in Geotechnical Engineering: The Skempton Conference, Royal Geographical Society, London, pp. 604–617 (2004)

Oztoprak, S., Bolton, M.D.: Stiffness of sands through a laboratory test database. Geotechnique 63(1), 54–70 (2013). https://doi.org/10.1680/geot.10.P.078

Shin, H., Santamarina, C.: Role of particle angularity on the mechanical behaviour of granular mixtures. J. Geotechn. Geoenviron. Eng. 139(2), 353–355 (2013). https://doi.org/10.1061/(ASCE)GT.1943-5606.0000768

Amirpour, S., Karray, M., Hussien, M.N.: Influence of particle-size and gradation on the stress-dilatancy of granular materials during drained triaxial compression. Int. J. Geomech. 17(9), 04017077 (2017). https://doi.org/10.1061/(ASCE)GM.1943-5622.0000951

Amirpour, S., Hussien, M.N., Karray, M.: Influence of particle-size and gradation on shear strength-dilation relation of granular materials. Can. Geotech. J. 56(2), 208–227 (2018). https://doi.org/10.1139/cgj-2017-0468

Simoni, A., Houlsby, G.T.: The direct shear strength and dilatancy of sand–gravel mixtures. Geotech. Geol. Eng. 24(523), 523–549 (2006)

Alshibli, K.A., Cil, M.B.: Influence of particle morphology on the friction and dilatancy of sand. J. Geotech. Geoenviron. Eng. 144(3), 04017118 (2018). https://doi.org/10.1061/(ASCE)GT.1943-5606.0001841

Bolton, M.D.: The strength and dilatancy of sands. Geotechnique 36(1), 65–78 (1986)

Guo, P., Su, X.: Shear strength, interparticle locking and dilatancy of granular materials. Can. Geotech. J. 44, 579–591 (2007)

Lee, J., Yun, T.S., Lee, D., Lee, J.: Assessment of Ko correlation to strength for granular materials. Soils Found. 53(4), 584–595 (2013). https://doi.org/10.1016/j.sandf.2013.06.009

Strahler, A., Stuedlein, A.W., Arduino, P.W.: Stress-strain response and dilatancy of sandy gravel in triaxial compression and plane strain. J. Geotech. Geoenviron. Eng. 142(4), 04015098 (2015). https://doi.org/10.1061/(ASCE)GT.1943-5606.0001435

Ashmawy, A.K., Sukumaran, B., Hoang, V.V.: Evaluating the influence of particle shape on liquefaction behaviour using discrete element modelling. In: Proceedings of the 13th International Offshore and Polar Engineering Conference, Honolulu, United States, 1089–1096 (2003)

Mair, K., Frye, K.M., Marone, C.: Influence of grain characteristics on the friction of granular shear zones. J. Geophys. Res. 107(B10), ECV4-9 (2002)

Kowalska, M.: Numerical study of the influence of dilatancy angle on bearing capacity and rotation of a gravity retaining wall. In: Proceedings of 15th Danube—European Conference on Geotechnical Engineering, Austria, vol. 2, pp. 1027–1032 (2014)

Arda, C., Zafarani, A.R., Bildik, S., Cinicioglu, O.: Influences of preshear stress state and density on shear band geometry. In: Proceedings of 4th International Conference on New Developments in Soil Mechanics and Geotechnical Engineering, Nicosia, North Cyprus (2016)

Soltanbeigi, B., Altunbas, A., Cinicioglu, O.: Influence of dilatancy on shear band characteristics of granular backfills. Europ. J. Environ. Civil Eng. (2019). https://doi.org/10.1080/19648189.2019.1572542

Rowe, P.W.: The stress-dilatancy relation for static equilibrium of an assembly of particles in contact. Proc. Royal Soc. London 269(1339), 500–527 (1962)

Josselin, De., de Jong, G.: Rowe’s stress-dilatancy relation based on friction. Geotechnique 26(3), 527–534 (1976)

Been, K., Jefferies, M.G., Hachey, J.: The critical state of sands. Geotechnique 41(3), 365–381 (1991)

Vaid, Y.P., Sasitharan, S.: The strength and dilatancy of sand. Can. Geotech. J. 29(3), 522–526 (1992)

Schanz, T., Vermeer, P.A.: Angles of friction and dilatancy of sand. Geotechnique 46(1), 145–151 (1996)

Hanna, A.: Determination of plane-strain shear strength of sand from the results of triaxial tests. Can. Geotech. J. 38(6), 1231–1240 (2001)

Chu, J., Kim, S.R., Oh, Y.N.: An experimental and theoretical study on the dilatancy of sands and clays. In: Proceedings of 9th Australia New Zealand Conference on Geomechanics, University of Auckland, New Zealand Geotechnical Society, vol. 2, pp. 654–660 (2004)

Ng, T.T.: Behavior of gravity deposited granular material under different stress paths. Can. Geotech. J. 42, 1644–5165 (2005)

Wanatowski, D., Chu, J.: Drained behaviour of Changi sand in triaxial and plane-strain compression. Geomech. Geoeng. 2(1), 29–39 (2007)

Chang, C.S., Yin, Z.: Modelling stress-dilatancy for sand under compression and extension loading conditions. J. Eng. Mech. 136(6), 777–786 (2010)

Cinicioglu, O., Abadkon, A., Altunbas, A.: Variation of friction angle and dilatancy for anisotropic cohesionless soils. In: Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, pp. 895–898 (2013)

Tatsuoka, F., Sakamoto, M., Kawamura, T.: Strength and deformation characteristics of sand in plane strain compression at extremely low pressures. Soils Found. 26(1), 65–84 (1986)

Wan, R.G., Guo, P.J.: A pressure and density dependent dilatancy model for granular materials. Soils Found. Jpn. Geotech. Soc. 39(6), 1–11 (1999)

Abadkon, A.: Strength and Dilatancy of Anisotropic Cohesionless Soils. PhD Thesis, Bogazici University, Istanbul, Turkey (2012)

Houlsby, G. T.: How the dilatancy of soils affects their behaviour. In: Proceedings of the 10th European Conference on Soil Mechanics and Foundation Engineering, Florence, Italy (1991)

Cinicioglu, O., Abadkon, A.: Dilatancy and friction angles based on insitu soil conditions. J. Geotech. Geoenviron. Eng. 141(4), 06014019 (2015). https://doi.org/10.1061/(ASCE)GT.1943-5606.0001272

Arda, C., Cinicioglu, O.: (2019) Kohezyonsuz Zeminlerin Tane Dağılım ve Şekil Özelliklerinin Aktif Göçme Yüzeyi Geometrisine Etkileri. Teknik Dergi 30(5): 9399–9420 https://doi.org/10.18400/tekderg.397658

Schofield, A.N.: Interlocking, peak and design strengths. Geotechnique 56(5), 357–358 (2006)

Chakraborty, T., Salgado, R.: Dilatancy and shear strength of sand at low confining pressures. Journal of Geotechnical and Geoenvironmental Engineering 136(3), 527–532 (2010)

Been, J., Jefferies, M.G.: A state parameter for sands. Geotechnique 35(2), 99–112 (1985). https://doi.org/10.1680/geot.1985.35.2.99

Wang, Z.L., Dafalias, Y.F., Li, Z.S., Makdisi, F.I.: State pressure index for modeling sand behavior. J. Geotech. Geoenviron. Eng. 128(6), 511–519 (2002). https://doi.org/10.1061/(ASCE)1090-0241(2002)128:6(511

Xiao, Y., Liu, H.: Elastoplastic constitutive model for rockfill materials considering particle breakage. Int. J. Geomech. 17(1), 04016041 (2017). https://doi.org/10.1061/(ASCE)GM.1943-5622.0000681

Xiao, Y., Sun, Y., Yin, F., Liu, H., Xiang, J.: Constitutive modeling for transparent granular soils. Int. J. Geomech. 17(7), 04016150 (2016). https://doi.org/10.1061/(ASCE)GM.1943-5622.0000857

Oda, M.: Initial fabrics and their relations to mechanical properties of granular material. Jpn. Soc. Soil Mech. Found. Eng. 12(1), 17–36 (1972)

Holubec, I., D’Appolonia, E.: Effect of particle shape on the engineering properties of granular soils. In: Evaluation of Relative Density and its Role in Geotechnical Projects Involving Cohesionless Soils, ASTM International, pp. 304–318 (1973)

Matsuoka, H.: A microscopic study on shear mechanism of granular materials. Soils Found. Jpn. Soc. Soil Mech. Found. Eng. 14(1), 29–43 (1973)

Santamarina, J.C., Cho, G.C.: Determination of critical state parameters in sandy soils—simple procedure. Geotech. Test. J. 24(2), 185–192 (2001)

Yang, J., Luo, X.D.: Exploring the relationship between critical state and particle shape for granular materials. J. Mech. Phys. Solids 84, 196–213 (2015). https://doi.org/10.1016/j.jmps.2015.08.001

Zheng, J., Hryciw, R.D.: Traditional soil particle sphericity, roundness, and surface roughness by computational geometry. Geotechnique 65(6), 494–506 (2015). https://doi.org/10.1680/geot.14.P.192

Schneider, C.A., Rasband, W.S., Eliceiri, K.W.: NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 9(7), 671–675 (2012)

ASTM: ASTM D4253: Standard test methods for maximum index density and unit weight of soils using a vibratory table. In: Annual Book of ASTM Standards (2006)

ASTM: ASTM D4254: Standard test methods for minimum index density and unit weight of soils and calculation of relative density. In: Annual Book of ASTM Standards (2006)

ASTM: ASTM D854–14: Standard test methods for specific gravity of soil solids by water pycnometer. In: Annual Book of ASTM Standards (2014)

ASTM: ASTM D422–63: Standard test methods for particle-size analysis of soils. In: Annual Book of ASTM Standards (2007)

ASTM: ASTM D7181–11: Standard test methods for consolidated drained triaxial compression test for soils. In: Annual Book of ASTM Standards (2011)

Giampa, J.R., Bradshaw, A.S.: A simple method for assessing the peak friction angle of sand at very low confining pressures. Geotech. Test. J. 41(4), 639–647 (2018)

Gezgin, A.T., Cinicioglu, O.: Consideration of locked-in stresses during backfill preparation. Geomech. Eng. 18(3), 247–258 (2019)

Mbarak, W., Cinicioglu, E.N., Cinicioglu, O.: SPT based determination of undrained shear strength: regression models and machine learning. Front. Struct. Civil Eng. 14(1), 185–198 (2020)

Acknowledgements

The authors would like to acknowledge that this study was funded by the Scientific and Technological Research Council of Turkey (TUBITAK Project 114M329).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arda, C., Cinicioglu, O. Influence of grain shape on stress-dilatancy parameters. Granular Matter 23, 22 (2021). https://doi.org/10.1007/s10035-021-01098-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-021-01098-2