Abstract

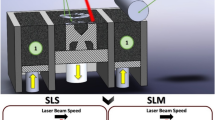

Selective laser sintering (SLS) is an additive manufacturing technology whereby one can 3D print parts out of a powdered material. However, in order to produce defect free parts of sufficient strength, the process parameters (laser power, scan speed, powder layer thickness, etc.) must be carefully optimized depending on material, part geometry, and desired final part characteristics. Computational methods are very useful in the quick optimization of such parameters without the need to run numerous costly experiments. Most published models of this process involve continuum-based techniques, which require the homogenization of the powder bed and thus do not capture the stochastic nature of this process. Thus, the aim of this research is to produce a reduced order computational model of the SLS process which combines the essential physics with fast computation times. In this work the authors propose a coupled discrete element-finite difference model of this process. The powder particles are modeled as discrete, thermally and mechanically interacting spheres. The solid, underneath substrate is modeled via the finite difference method. The model is validated against experimental results in the literature and three-dimensional simulations are presented.

Similar content being viewed by others

Notes

The powder bed density is calculated by adding the volume of all portions of all particles located within a 30 \(\upmu \)m layer from the bottom substrate and then dividing by the volume of this layer (the cross section of the layer is 1000 \(\upmu \)m \(\times \) 500 \(\upmu \)m and height is 30 \(\upmu \)m).

References

Mechanical and physical properties of the austenitic chromium–nickel stainless steels at elevated temperatures 3rd edn. The International Nickel Company Inc., New York (1968)

Adams, G., Nosonovsky, M.: Contact modeling—forces. Tribol. Int. 33, 431–442 (2000)

Antony, K., Arivazhagan, N., Senthilkumaran, K.: Numerical and experimental investigations on laser melting of stainless steel 316L metal powders. J. Manuf. Process. 16(3), 345–355 (2014)

Bonacina, C., Comini, G., Fasano, A., Primicerio, M.: Numerical solution of phase-change problems. Int. J. Heat Mass Transf. 16(10), 1825–1832 (1973)

Campello, E.M., Zohdi, T.I.: A computational framework for simulation of the delivery of substances into cells. Int. J. Numer. Methods Biomed. Eng. 30, 1132–1152 (2014)

Dai, D., Gu, D.: Thermal behavior and densification mechanism during selective laser melting of copper matrix composites: Simulation and experiments. Mater. Des. 55, 482–491 (2014)

Dong, L., Makradi, A., Ahzi, S., Remond, Y.: Three-dimensional transient finite element analysis of the selective laser sintering process. J. Mater. Process. Technol. 209(2), 700–706 (2009)

Ebert, R., Ullmann, F., Hildebrandt, D., Schille, J., Hartwig, L., Kloetzer, S., Streek, A., Exner, H.: Laser processing of tungsten powder with femtosecond laser radiation. J. Laser Micro Nanoeng. 7(1), 38–43 (2012)

Fischer, P., Locher, M., Romano, V., Weber, H., Kolossov, S., Glardon, R.: Temperature measurements during selective laser sintering of titanium powder. Int. J. Mach. Tools Manuf. 44(12–13), 1293–1296 (2004)

Galindo-Torres, S.: A coupled discrete element lattice Boltzmann method for the simulation of fluid solid interaction with particles of general shapes. Comput. Methods Appl. Mech. Eng. 265, 107–119 (2013)

Ganeriwala, R., Zohdi, T.I.: Multiphysics modeling and simulation of selective laser sintering manufacturing processes. Proc. CIRP 14(0), 299–304 (2014). (6th CIRP international conference on high performance cutting, HPC2014)

Gusarov, A., Kruth, J.P.: Modelling of radiation transfer in metallic powders at laser treatment. Int. J. Heat Mass Transf. 48(16), 3423–3434 (2005)

Gusarov, A.V., Yadroitsev, I., Bertrand, P., Smurov, I.: Model of radiation and heat transfer in laser-powder interaction zone at selective laser melting. J. Heat Transf. 131(7), 072,101 (2009)

Hecht, J.: Understanding Lasers. Wiley, Hoboken (2008)

Hodge, N., Ferencz, R., Solberg, J.: Implementation of a thermomechanical model for the simulation of selective laser melting. Comput. Mech. 54, 33–51 (2014)

Johnson, K.: Contact Mechanics. Cambridge University Press, Cambridge (1987)

Khairallah, S.A., Anderson, A.: Mesoscopic simulation model of selective laser melting of stainless steel powder. J. Mater. Process. Technol. 214(11), 2627–2636 (2014)

Kolossov, S., Boillat, E., Glardon, R., Fischer, P., Locher, M.: 3D FE simulation for temperature evolution in the selective laser sintering process. Int. J. Mach. Tools Manuf. 44(2–3), 117–123 (2004)

Körner, C., Attar, E., Heinl, P.: Mesoscopic simulation of selective beam melting processes. J. Mater. Process. Technol. 211(6), 978–987 (2011)

Körner, C., Bauereiß, A., Attar, E.: Fundamental consolidation mechanisms during selective beam melting of powders. Modell. Simul. Mater. Sci. Eng. 21(8), 085,011 (2013)

Kruth, J.P., Levy, G., Klocke, F., Childs, T.: Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann. Manuf. Technol. 56(2), 730–759 (2007)

Kumar, S.: Comprehensive Materials Processing, vol. 10. Elsevier, Amsterdam (2014)

LeVeque, R.: Finite Difference Methods for Ordinary and Partial Differential Equations: Steady-State and Time-Dependent Problems. Society for Industrial and Applied Mathematics, Philadelphia (2007)

Limmaneevichitr, C., Kou, S.: Experiments to simulate effect of Marangoni convection on weld pool shape. Weld. J. 79, 231s–237s (2000)

Maeda, K., Childs, T.: Laser sintering (SLS) of hard metal powders for abrasion resistant coatings. J. Mater. Process. Technol. 149(1–3), 609–615 (2004)

Matsumoto, M., Shiomi, M., Osakada, K., Abe, F.: Finite element analysis of single layer forming on metallic powder bed in rapid prototyping by selective laser processing. Int. J. Mach. Tools Manuf. 42(1), 61–67 (2002)

Muhieddine, M., Canot, E., March, R.: Various approaches for solving problems in heat conduction with phase change. Int. J. Finite Vol. 6, 66–85 (2009)

Munson, B., Young, D., Okiishi, T.: Fundamentals of Fluid Mechanics. Wiley, Hoboken (2005)

Nelson, J., Xue, S., Barlow, J.W., Beaman, J.J., Beaman, J., Marcus, H.L., Bourell, D.: Model of the selective laser sintering of bisphenol-A polycarbonate. Ind. Eng. Chem. Res. 32, 2305–2317 (1993)

Perkins, E.D., Williams, J.R.: Generalized spatial binning of bodies of different sizes. In: Cook, B.K., Jensen, R.P. (eds.) Discrete Element Methods: Numerical Modeling of Discontinua, pp. 52–55. ASCE, Reston (2002)

Schmidt, M., Pohle, D., Rechtenwald, T.: Selective laser sintering of PEEK. CIRP Ann. Manuf. Technol. 56(1), 205–208 (2007)

Shifeng, W., Shuai, L., Qingsong, W., Yan, C., Sheng, Z., Yusheng, S.: Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. J. Mater. Process. Technol. 214, 2660–2667 (2014)

Simchi, A.: Direct laser sintering of metal powders: mechanism, kinetics and microstructural features. Mater. Sci. Eng. A 428(1–2), 148–158 (2006)

Simchi, A., Pohl, H.: Effects of laser sintering processing parameters on the microstructure and densification of iron powder. Mater. Sci. Eng. A 359(1–2), 119–128 (2003)

Steen, W.M., Mazumder, J.: Laser Material Processing. Springer, London (2010)

Tan, K., Chua, C., Leong, K., Cheah, C., Cheang, P., Abu Bakar, M., Cha, S.: Scaffold development using selective laser sintering of polyetheretherketone hydroxyapatite biocomposite blends. Biomaterials 24(18), 3115–3123 (2003)

Wellmann, C., Wriggers, P.: A two-scale model of granular materials. Comput. Methods Appl. Mech. Eng. 205–208, 46–58 (2012)

Williams, J.M., Adewunmi, A., Schek, R.M., Flanagan, C.L., Krebsbach, P.H., Feinberg, S.E., Hollister, S.J., Das, S.: Bone tissue engineering using polycaprolactone scaffolds fabricated via selective laser sintering. Biomaterials 26(23), 4817–27 (2005)

Zeng, K., Pal, D., Stucker, B.: A review of thermal analysis methods in laser sintering and selective laser melting. In: 23rd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, pp. 796–814 (2012)

Zohdi, T.: Rapid simulation of laser processing of discrete particulate materials. Arch. Comput. Methods Eng. 20(4), 309–325 (2013)

Zohdi, T.: Additive particle deposition and selective laser processing-a computational manufacturing framework. Comput. Mech. 54, 171–191 (2014)

Zohdi, T.: A direct particle-based computational framework for electrically enhanced thermo-mechanical sintering of powdered materials. Math. Mech. Solids 19(1), 93–113 (2014)

Acknowledgments

The authors would like to express their gratitude towards Ramesh Subramanian and Marco Brunelli of Siemens Energy, Inc. for funding this research. Additionally, the input of other members of the Siemens Corporation was useful in the formulation and validation of this approach. Finally the authors would like to thank fellow members of the CMRL lab at UC Berkeley for many fruitful discussions and their aid in the proofreading and editing of this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ganeriwala, R., Zohdi, T.I. A coupled discrete element-finite difference model of selective laser sintering. Granular Matter 18, 21 (2016). https://doi.org/10.1007/s10035-016-0626-0

Received:

Published:

DOI: https://doi.org/10.1007/s10035-016-0626-0