Abstract

The importance of particle rotation to the mechanical behavior of granular materials subject to quasi-static shearing has been well recognized in the literature. Although the physical source of the resistance to particle rotation is known to lie in the particle surface topography, it has been conveniently studied using the rolling resistance model installed typically on spherical particles within the DEM community. However, there has been little effort on assessing the capability of the rolling resistance model to produce more realistic particle rotation behavior as exhibited by irregular-shaped particles. This paper aims to eliminate this deficiency by making a comprehensive comparison study on the micromechanical behavior of assemblies of irregular-shaped particles and spherical particles installed with the rolling resistance model. A variety of DEM analysis techniques have been applied to elucidate the full picture of micromechanical processes occurring in the two types of granular materials with different particle-level anti-rotation mechanisms. Simulation results show that the conventional rheology-type rolling resistance models cannot reproduce the particle rotation and strain localization behavior as displayed by irregular-shaped materials, although they demonstrate clear effects on the macroscopic strength and dilatancy behavior, as have been adequately documented in the literature. More insights into the effects of particle-level anti-rotation mechanism are gained from an in-depth inter-particle energy dissipation analysis.

Similar content being viewed by others

References

Iwashita, K., Oda, M.: Rolling resistance at contacts in simulation of shear band development by DEM. J. Eng. Mech. ASCE 124, 285–292 (1998)

Kuhn, M.R., Katalin, B.: Contact rolling and deformation in granular media. Int. J. Solids Struct. 41(21), 5793–5820 (2004)

Alonso-Marroquin, F., Vardoulakis, I., Herrmann, H.J., Weatherley, D., Mora, P.: Effect of rolling on dissipation in fault gouges. Phys. Rev. E 74(3), 031306 (2006)

Mohamed, A., Gutierrez, M.: Comprehensive study of the effects of rolling resistance on the stress–strain and strain localization behavior of granular materials. Granul. Matter 12, 527–541 (2010)

Tordesillas, A., Walsh, D.C.: Incorporating rolling resistance and contact anisotropy in micromechanical models of granular media. Powder Technol. 124(1), 106–111 (2002)

Zhang, W.C., Wang, J.F., Jiang, M.J.: DEM-aided discovery of the relationship between energy dissipation and shear band formation considering the effects of particle rolling resistance. J. Geotech. Geoenviron. Eng., online first (2013). doi:10.1061/(ASCE)GT.1943-5606.0000890

Astrom, J.A., Timonen, J.: Spontaneous formation of densely packed shear bands of rotating fragments. Eur. Phys. J. E 35(40), 1–5 (2012)

Holubec, I., D’Appolonia, E.: Effect of particle shape on the engineering properties of granular soils. Am. Soc. Test. Mater. ASTM STP 523, 304–318 (1973)

Guo, P., Su, X.: Shear strength, interparticle locking, and dilatancy of granuar materials. Can. Geotech. J 44(5), 579–591 (2007)

Tsomokos, A., Georgiannou, V.N.: Effect of grain shape and angularity on the undrained response of fine sands. Can. Geotech. J. 47(5), 539–551 (2010)

Cundall, P.A., Strack, O.D.: A discrete numerical-model for granular assemblies. Geotechnique 29, 47–65 (1979)

Emeriault, F., Chang, C.S.: Interparticle forces and displacements in granular materials. Comput. Geotech. 20(3–4), 223–244 (1997)

Sitharam, T.G.: Micromechanical modeling of granular materials: effect of confining pressure on mechanical behavior. Mech. Mater. 31(10), 653–665 (1999)

Liu, S.H., Matsuoka, H.: Microscopic interpretation on a stress–dilatancy relationship of granular materials. Soils Found. 43(3), 73–84 (2003)

Wang, J., Gutierrez, M.S.: Discrete element simulations of direct shear specimen scale effects. Géotechnique 60(5), 395–409 (2010)

Guo, P.: Critical length of force chains and shear band thickness in dense granular materials. Acta Geotech. 7, 41–55 (2012)

Iwashita, K., Oda, M.: Micro-deformation mechanism of shear banding process based on modified distinct element method. Powder Technol 109, 192–205 (2000)

Jiang, M.J., Yu, H.S., Harris, D.: A novel discrete model for granular material incorporating rolling resistance. Comput. Geotech. 32, 340–357 (2005)

Ai, J., Chen, J., Rotter, J.M., Ooi, J.Y.: Assessment of rolling resistance models in discrete element simulations. Powder Technol. 206, 269–282 (2011)

Wensrich, C.M., Katterfeld, A.: Rolling friction as a technique for modelling particle shape in DEM. Powder Technol. 217, 409–417 (2012)

Nouguier-Lehon, C., Cambou, B., Vincens, E.: Influence of particle shape and angularity on the behaviour of granular materials: a numerical analysis. Int. J. Numer. Anal. Methods Geomech. 27, 1207–1226 (2003)

Nouguier-Lehon, C.: Effect of the grain elongation on the behaviour of granular materials in biaxial compression. Computes Rendus Mecanique 338, 587–595 (2010)

Antonya, S.J., Momoha, R.O., Kuhnb, M.R.: Micromechanical modelling of oval particulates subjected to bi-axial compression. Comput. Mater. Sci. 29, 494–498 (2004)

Mahmood, Z., Iwashita, K.: Influence of inherent anisotropy on mechanical behavior of granular materials based on DEM simulations. Int. J. Numer. Anal. Methods Geomech. 34, 795–819 (2010)

Mahmood, Z., Iwashita, K.: A simulation study of microstructure evolution inside the shear band in biaxial compression test. Int. J. Numer. Anal. Methods Geomech. 35, 652–667 (2011)

Abedi, S., Mirghasemi, A.A.: Particle shape consideration in numerical simulation of assemblies of irregularly shaped particles. Particulology 9, 387–397 (2011)

Estrada, N., Azema, E., Radjai, F.: Identification of rolling resistance as a shape parameter in sheared granular media. Phys. Rev. E 84(1), 011306 (2011)

Favier, J.F., et al.: Shape representation of axisymmetrical, non-spherical particles in discrete element simulation using multi-element model particles. Eng. Comput. 16(4), 467–480 (1999)

Matuttis, H.G., Luding, S., Herrmann, H.J.: Discrete element simulations of dense packings and heaps made of spherical and non-spherical particles. Powder Technol. 109, 278–292 (2000)

Bagherzadeh-Khalkhali, A., Mirghasemi, A.A., Mohammadi, S.: Micromechanics of breakage in sharp-edge particles using combined DEM and FEM. Particuolagy 6, 347–361 (2008)

Bagherzadeh-Khalkhali, A., Mirghasemi, A.A.: Numerical and experimental direct shear tests for coarse-grained soils. Particuolagy 7, 83–91 (2009)

Alonso-Marroquin, F., Luding, S., Herrmann, H.J., Vardoulakis, I.: Role of anisotropy in the elastoplastic response of a polygonal packing. Phys. Rev. E 71, 051304 (2005)

Alonso-Marroquin, F.: Spheropolygons: a new method to simulate conservative and dissipative interactions between 2D complex-shaped rigid bodies. Europhys. Lett. 83, 14001 (2008)

Alonso-Marroquín, F., Wang, Y.: An efficient algorithm for granular dynamics simulations with complex-shaped objects. Granul. Matter 11, 317–329 (2009)

Galindo-Torres, S.A., Munoz, J.D., Alonso-Marroquin, F.: Minkowski-Voronoi diagrams as a method to generate random packings of spheropolygons for the simulation of soils. Phys. Rev. E 82, 056713 (2010)

Ashmawy, A.K., Sukumaran, B., Hoang, V.V.: Evaluating the influence of particle shape on liquefaction behavior using discrete element modeling. In: Proceedings of The 13th (2003) International Offshore And Polar Enginerring Conference, vol. 2, pp. 542–549 (2003)

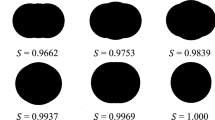

Riley, N.A.: Projection sphericity. J. Sediment. Petrol 11, 94–97 (1941)

Blott, S.J., Pye, K.: Particle shape: a review and new methods of characterization and classification. Sedimentology 55(1), 31–63 (2008)

Sukumaran, B., Ashmawy, A.K.: Quantitative characterisation of the geometry of discrete particles. Geotechnique 51(7), 619–627 (2001)

Bardet, J.P., Huang, Q.: Rotational stiffness of cylindrical particle contacts. In: Proceeding on 2nd International Conference on Micromechanics of Granular, Media, pp. 39–43 (1993)

Sakaguchi, H., Ozaki, E., Igarashi, T.: Plugging of the flow of granular materials during the discharge from a silo. Int. J. Mod. Phys. B 7, 1949–1963 (1993)

Itasca: PFC2D Manual (Version 4.0). Itasca Consulting Group Inc, Minneapolis (2008)

Astrom, J.A., Herrmann, H.J., Timonen, J.: Granular packings and fault zones. Phys. Rev. Lett. 84(4), 638–641 (2000)

Alonso-Marroquin, F., Herrmann, H.J.: Calculation of the incremental stress–strain relation of a polygonal packing. Phys. Rev. E 66(2), 021301 (2002)

Wang, Y.H., Leung, S.C.: Characterization of cemented sand by experimental and numerical investigations. J. Geotech. Geoenviron. Eng. ASCE 134(7), 992–1004 (2008)

Wang, J., Yan, H.B.: On the role of particle breakage in the shear failure behavior of granular soils by DEM. Int. J. Numer. Anal. Methods Geomech, Online first (2011). doi:10.1002/nag

Wang, J., Yan, H.B.: DEM analysis of energy dissipation in crushable soils. Soils Found. 52(4), 644–657 (2012)

Bolton, M.D., Nakata, Y., Cheng, Y.P.: Micro-and macro-mechanical behavior of DEM crushable materials. Geotechnique 58(6), 471–480 (2008)

Wang, J., Gutierrez, M.S., Dove, J.E.: Numerical studies of shear banding in interface shear tests using a new strain calculation method. Int. J. Numer. Anal. Meth. Geomech. 31(12), 1349–1366 (2007a)

Wang, J., Dove, J.E., Gutierrez, M.S.: Discrete-continuum analysis of shear band in the direct shear test. Géotechnique 57(6), 527–536 (2007b)

Wang, J., Jiang, M.J.: Unified soil behavior of interface shear test and direct shear test under the influence of lower moving boundaries. Granul. Matter 13(5), 631–641 (2011)

Azema, A., Radja, F.: Force chains and contact network topology in sheared packings of elongated particles. Phys. Rev. E 85, 031303 (2012)

Acknowledgments

This research was financially supported by National Science Foundation of China for Young Investigators with Grant No. 51109182, Research Grant No. SKLGP2012K019 from the State Key Laboratory of Geohazard Prevention and Geo-environment Protection of Chengdu University of Technology, Strategic Research Grant No. 7008180 from City University of Hong Kong, Grant No. 2012BAK10B00 from Ministry of National Science and Technology and Key Program No. 2009CDA007 of Natural Science Foundation of Hubei.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, B., Huang, R., Wang, H. et al. DEM investigation of particle anti-rotation effects on the micromechanical response of granular materials. Granular Matter 15, 315–326 (2013). https://doi.org/10.1007/s10035-013-0409-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-013-0409-9