Abstract

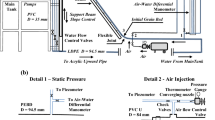

Pneumatic conveying of bulk materials has become an important technology in many industries: from pharmaceuticals to petro-chemicals and power generation. Particulate segregation has been investigated in many solids handling processes. However, little work has been published on the segregation and mixing in pneumatic conveying pipelines, particularly in dense phase pneumatic conveying. Due to the character of dense phase flow, it is difficult to investigate the segregation in a flowing plug. A sampling device was designed and built to take samples from the pneumatic conveying pipeline after “catching a plug”. Several experiments were conducted over a range of gas–solids flow conditions with 3 mm nylon pellets and 3 mm ballotini as a segregating mixture. Experimental data combined with video footage were analysed to describe the segregation and mixing of solids plugs in pipes. This investigation provides initial research on establishing a segregation index in a flowing plug. A gas–solids two-dimensional mathematical model was developed for plug flow of a nylon-glass particulate mixture in a horizontal pipeline in dense phase pneumatic conveying. The model was developed based on the discrete element method (DEM). The model was used to simulate the motion of particles both in a homogeneous flow and as binary mixtures taking into account the various interactions between gas, particles and pipe wall. For the gas phase, the Navier Stokes equations were integrated by the semi-implicit method for pressure-linked equations (SIMPLE) using the scheme of Patankar employing the staggered grid system. For the particle motion the Newtonian equations of motion of individual particles were integrated, where repulsive and damping forces for particle collision, the gravity force, and the drag force were taken into account. For particle contact, a model with a simple non-linear spring and dash pot model for both normal and tangential components was used. This model employed a mixture of 3 mm pellets and ballotini as virtual materials with properties of nylon and glass. The results from the model are discussed and compared with experimental work and show qualitative agreement. Further modelling and experimental work in key areas is proposed.

Similar content being viewed by others

References

De Silva, S.R.: Mixing and segregation in industrial processes, IFPRI Report SAR 12-20 Tel-Tek Report 410037-1 (1997)

Marjanovic, P. et al.: Final report—ECSC targeted project No 7220-EA/132 (1999)

Mosby J., Enstad G.G.: Segregation of Particulate Solids: Processes, Mechanisms, and Counteractions. Process Engineering Publisher, Prague (1996)

Jones, M.G., Marjanovic, P., McGlinchey, D.: An investigation of degradation and segregation in typical coal handling processes, Proceedings of the third Israeli conference for conveying and handling of particulate solids, The Dead Sea, May 29–June 1 (2000)

McGlinchey, D., Jones, M.G., Marjanovic, P.: The Blending and Segregation of Coal for the UK Industrial Market, Bulk Solids Handling, vol. 19 No 3, pp. 345–351, Trans Tech Publications, July/September (1999)

Bates L.: User Guide to Segregation. British Materials Handling Board, Cheshire (1997)

Xiang J.: Investigation of Particle Motion in Dense Phase Pneumatic Conveying. Ph.D. thesis, Glasgow Caledonian University, Glasgow (2004)

McGlinchey, D., Marjanovic, P., Cook, S., Jones, M.G.: Segregation in pneumatic conveying lines. The international conference on powder and bulk solids handling, organised by IMechE, London UK (2000)

Cundall P.A., Strack O.D.L.: A discrete numerical model for granular assemblies. G′eotechnique 29, 47–65 (1979)

Tsuji Y., Tanaka T., Ishida T.: Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 71, 239–250 (1992)

Xiang J., McGlinchey D.: Numerical simulation of particle motion in dense phase pneumatic conveying. Granular Matter 6, 167–172 (2004)

Mindlin, R.D., Deresiewicz, H.: Elastic spheres in contact under varying oblique forces. J. Appl. Mech. pp. 327–344 (1953)

Ergun S.: Fluid flow through packed columns. Chem. Eng. Prog. 48(2), 89 (1952)

Wen C.Y., Yu Y.H.: Mechanics of fluidization. Chem. Eng. Prog. Symp. Series 62, 100 (1966)

Pnueli D., Gutfinger C.: Fluids Mechanics. Cambridge University Press, Cambridge (1992)

Tsuji Y., Kawaguchi T., Tanaka T.: Discrete particle simulation of two-dimensional fluidized bed. Powder Technol. 77(1), 79–87 (1993)

Patankar S.V.: Numerical Heat Transfer and Fluid Flow. Hemisphere, New York (1980)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiang, J., McGlinchey, D. & Latham, JP. An investigation of segregation and mixing in dense phase pneumatic conveying. Granular Matter 12, 345–355 (2010). https://doi.org/10.1007/s10035-010-0171-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-010-0171-1