Abstract.

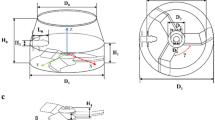

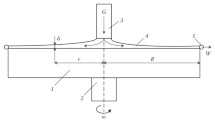

Changes of torque during fine material (foundry dolomite) granulation in a horizontal drum granulator at changing wetting parameters were studied. The variable parameters were droplet diameter and wetting of granular material. The bed of loose material was sprayed during feeding, at a constant liquid flow rate V l = 0.012 m3/h. The size of wetting liquid droplets was changed using different rates of air flow through pneumatic spraying nozzles in the range from V p = 1.0 to 3.0 m3/h and applying a sprinkler which supplied (drop-wise) the liquid uniformly along the entire drum length. In each test, instantaneous values of torque on the granulator shaft were measured in 1 s time intervals. The effect of droplet size and moisture content of the bed of granular material on torque in the whole granulation cycle was estimated. It was found that bed wetting conditions had a significant influence on the nucleation and growth of agglomerates. A minimum (boundary) size of liquid droplets, at which the bed is not transformed into granulated material, depends on the total amount of liquid supplied at the wetting stage. Changes of torque during the drum granulation are a good representation of the phenomena related to the transformation of wetted feed into granulated product and can be an easy indicator of the process.

Similar content being viewed by others

References

A. Heim, T. Gluba & A. Obraniak, Investigation of Torque during Drum Granulation, Physicochemical Problems of Mineral Processing, (1999), p. 49–62

T. Gluba, A. Heim & A. Obraniak, Driving Torque in the Process of Drum Granulation, CHISA 2000, (Prague, 2000)

P. C. Kapur, S. Ranjan & D. W. A. Fuerstenau, Cascade-Cataract Charge Flow Model for Power Draft of Tumbling Mills. Int. J. Miner. Proc., 36, (1992), p. 9–29

A. Heim, T. Gluba & A. Obraniak, The Effect of the Process and Equipment Parameters on the Value of Torque during the Drum Granulation, Zeszyty Naukowe PL, 28, (2000) p. 91–99

J. Mellmann, The Transverse Motion of Solids in Rotating Cylinders – Forms of Motion and Transition Behavior, Powder Technol, 118, (2001), p. 251–270

K. Terashita, M. Kato & A. Ohike, Analysis of end-point with power consumption in high speed mixer. Chem. Pharm. Bull, 38, (1990), p. 1977–1982

P. Holm, T. Schaefer & H. G. Kristensen, Granulation in high speed mixers. Part V: Power consumption and temperature changes during granulation. Powder Technology, 43, (1985), p. 213–223

P. Holm, T. Schaefer & H. G. Kristensen, Granulation in high speed mixers. Part VI: Effects of process conditions on power consumption and granule growth. Powder Technology, 3, (1993), p. 286–293

A. Heim, T. Gluba & A. Obraniak, The Effect of Wetting Parameters on Torque during Drum Granulation, CHISA 2002, (Prague, 2002)

J. D. Litster, K. P. Hapgood, J. N. Michaels, A. Sims, M. Roberts, S. K. Kameneni & T. Hsu, Liquid distribution in wet granulation: dimensionless spray flux, Powder Technology 114, (2001), p. 32–39

S. M. Iveson & J. D. Litster, Growth regime map for liquid-bound granules. AIChE J. 44, (1998), p. 1510–1518

P. C. Kapur, Balling and granulation, Adv. Chem. Eng. 10, (1978), p. 55–123

F. Hoornaert, P. A. L. Wauters, G. M. H. Meesters, S. E. Pratsinis & B. Scarlett, Agglomeration behaviour of powders in a Lodige mixer granulator, Powder Technol. 96, (1998), p. 116–128

P. J. Sherington, The granulation of sand as an aid to understanding fertilizer granulation, Chem. Eng. (1968) 201–215

C. E. Capes & P. V. Danckwerts, Granule formation by the agglomeration of damp powders: Part l. The mechanism of granule growth, Trans. Inst. Chem. Eng. 43, (1965), p. 116–124

S. M. Iveson, P. A. L. Wauters, S. Forrest, J. D. Litster, G. M. H. Meesters & B. Scarlett, Growth regime map for liquid-bound granules: further development and experimental validation. Powder Technology 117, (2001), p. 83–97

Author information

Authors and Affiliations

Corresponding author

Additional information

The work was carried out within the project no. 4 T09C 023 22. financed by the State Committee for Scientific Research in the years 2002–2005.

Rights and permissions

About this article

Cite this article

Heim, A., Gluba, T. & Obraniak, A. The effect of the wetting droplets size on power consumption during drum granulation. GM 6, 137–143 (2004). https://doi.org/10.1007/s10035-004-0169-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s10035-004-0169-7