Abstract

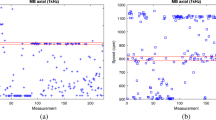

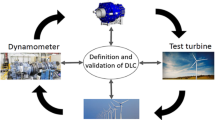

Drivetrain failures result in the largest downtime per failure among the different turbine components. To minimize O&M costs, it is therefore essential to be able to anticipate failure events sufficiently in advance such that scheduled maintenance can take place. Moreover, a root cause for the failure should be identified, allowing to incorporate this knowledge in future design iterations, thereby increasing the reliability of the machine. In offshore wind energy, high-frequency SCADA (1 Hz) and vibration data (>20 kHz) are becoming increasingly available to monitor machine performance and health. This paper presents a twofold approach for monitoring drivetrain health and load history based on these two data sources. First, SCADA data is used to extract different design load cases (DLCs), described in IEC 61400‑3. Second, vibration data is used for advanced signal analysis to detect potential incipient bearing or gear defects in the drivetrain. It is shown that the efficacy of this vibration analysis is further enhanced by combining it with operating condition information from the SCADA data.

Zusammenfassung

Ausfälle des Antriebsstrangs verursachen von allen Turbinenkomponenten die größte Ausfallzeit pro Ausfall. Um die Betriebs- und Wartungskosten zu minimieren, ist es daher von entscheidender Bedeutung, dass Ausfallereignisse so frühzeitig erkannt werden, dass eine planmäßige Wartung durchgeführt werden kann. Darüber hinaus sollte die Fehlerursache identifiziert werden, um dieses Wissen in zukünftige Konstruktionsiterationen einfließen zu lassen und so die Zuverlässigkeit der Anlage zu erhöhen. In der Offshore-Windenergie werden zunehmend hochfrequente SCADA- (1 Hz) und Schwingungsdaten (>20 kHz) zur Überwachung der Maschinenleistung und des Maschinenzustands verfügbar. In diesem Beitrag wird ein zweifacher Ansatz zur Überwachung des Zustands des Antriebsstrangs und des Lastverlaufs auf der Grundlage dieser beiden Datenquellen vorgestellt. Erstens werden SCADA-Daten verwendet, um verschiedene Auslegungslastfälle (DLCs) zu extrahieren, die in IEC 61400-3 beschrieben sind. Zweitens werden die Schwingungsdaten für eine erweiterte Signalanalyse verwendet, um mögliche beginnende Lager- oder Getriebeschäden im Antriebsstrang zu erkennen. Es wird gezeigt, dass die Wirksamkeit dieser Schwingungsanalyse durch die Kombination mit Betriebszustandsinformationen aus den SCADA-Daten weiter verbessert wird.

Similar content being viewed by others

References

Walsh C et al (2019) Offshore wind in europe—key trends and statistics 2019. Wind Europe, Brussels

Short W, Packey DJ, Holt T (1995) A manual for the economic evaluation of energy efficiency and renewable energy technologies. tech. rep. National Renewable Energy Lab, Golden

Helsen J, Vanhollebeke F, Vandepitte D, Desmet W (2012) Some trends and challenges in wind turbine upscaling. In: Proceedings of ISMA International Conference On Noise And Vibration 2012, vol 6, pp 4345–4359

Wind Energy Technologies Office (2015) Statistics show bearing problems cause the majority of wind turbine gearbox failures

Peeters C, Guillaume P, Helsen J (2018) Vibration-based bearing fault detection for operations and maintenance cost reduction in wind energy. Renew Energy 116:74–87

Leahy K, Gallagher C, Bruton K, O’Donovan P, O’Sullivan DT (2017) Automatically identifying and predicting unplanned wind turbine stoppages using scada and alarms system data: case study and results. J Phys Conf Ser 926:12011

van Binsbergen D, Soares MN, Pedersen E, Nejad AR (2022) A physics-, scadabased remaining useful life calculation approach for wind turbine drivetrains. J Phys Conf Ser 2265:32079

Korkos P, Linjama M, Kleemola J, Lehtovaara A (2021) Data annotation and feature extraction in fault detection in a wind turbine hydraulic pitch system. Renew Energy 85:692–703

Daems PJ, Guo Y, Sheng S, Peeters C, Guillaume P, Helsen J (2020) Gaining in-sights in loading events for wind turbine drivetrain prognostics. In: Turbomachinery technical conference & exposition

Hannesdóttir Á, Kelly M (2019) Detection and characterization of extreme wind speed ramps. Wind Energy Sci 4(3):385–396

de Azevedo HDM, Araújo AM, Bouchonneau N (2016) A review of wind turbine bearing condition monitoring: state of the art and challenges. Renew Sustain Energy Rev 56:368–379

Lu B, Li Y, Wu X, Yang Z (2009) A review of recent advances in wind turbine condition monitoring and fault diagnosis. In: 2009 IEEE power electronics and machines in wind applications, pp 1–7

Tchakoua P, Wamkeue R, Ouhrouche M, Slaoui-Hasnaoui F, Tameghe TA, Ekemb G (2014) Wind turbine condition monitoring: state-of-the-art review, new trends, and future challenges. Energies 7(4):2595–2630

Peeters C, Guillaume P, Helsen J (2017) A comparison of cepstral editing methods as signal pre-processing techniques for vibration-based bearing fault detection. Mech Syst Signal Process 91:354–381

Peeters C, Leclere Q, Antoni J, Lindahl P, Donnal J, Leeb S, Helsen J (2019) Review and comparison of tacholess instantaneous speed estimation methods on experimental vibration data. Mech Syst Signal Process 129:407–436

Nejad AR, Keller J, Guo Y, Sheng S, Polinder H, Watson S, Helsen J (2022) Wind turbine drivetrains: state-of-the-art technologies and future development trends. Wind Energy Sci 7(1):387–411

Helsen J, Peeters C, Doro P, Ververs E, Jordaens PJ (2017) Wind farm operation and maintenance optimization using big data. In: 2017 IEEE Third International Conference on big data computing service and applications (BigDataService). IEEE, pp 179–184

Peeters C, Antoni J, Helsen J (2020) Blind filters based on envelope spectrum sparsity indicators for bearing and gear vibration-based condition monitoring. Mech Syst Signal Process 138:106556

Helsen J, Peeters C, Verstraeten T, Verbeke J, Gioia N, Nowé A (2018) Fleet-wide condition monitoring combining vibration signal processing and machine learning rolled out in a cloud-computing environment. In: International Conference on Noise and Vibration Engineering (ISMA), pp 17–19

Gioia N, Daems PJ, Peeters C, El-Kafafy M, Guillaume P, Helsen J (2019) Influence of the harmonics on the modal behavior of wind turbine drivetrains. In: Rotating machinery, vibro-acoustics & laser vibrometry, vol 7. Springer, Cham, pp 231–238

Koukoura S, Peeters C, Helsen J, Carroll J (2020) Investigating parallel multi-step vibration processing pipelines for planetary stage fault detection in wind turbine drivetrains. J Phys Conf Ser 1618(2):22054

Daems PJ, Gioia N, Vervaeck H, Peeters C, Verbeke J, Guo Y, Helsen J (2019) Automatic detection of events critical for drivetrain health and lifetime from long-term field measurements. In: Conference for wind power drives 2019: conference proceedings. Books on Demand, p 405

Soares MN, Gyselinck J, Mollet Y, Peeters C, Gioia N, Helsen J (2018) Vibration-based rotor-side-converter open-switch-fault detection in DFIGs for wind turbines. In: 2018 IEEE International Conference on Prognostics and Health Management (ICPHM). IEEE, pp 1–6

Gioia N, Peeters C, Guillaume P, Helsen J (2019) Identification of noise, vibration and harshness behavior of wind turbine drivetrain under different operating conditions. Energies 12(17):3401

Helsen J, Gioia N, Peeters C, Jordaens PJ (2017) Integrated condition monitoring of a fleet of offshore wind turbines with focus on acceleration streaming processing. J Phys Conf Ser 842(1):12052

Jamil F, Verstraeten T, Nowé A, Peeters C, Helsen J (2022) A deep boosted transfer learning method for wind turbine gearbox fault detection. Renew Energy 197:331–341

Peeters C, Antoni J, Leclère Q, Verstraeten T, Helsen J (2022) Multi-harmonic phase demodulation method for instantaneous angular speed estimation using harmonic weighting. Mech Syst Signal Process 167:108533

Daems PJ, Peeters C, Guillaume P, Helsen J (2022) Removal of non-stationary harmonics for operational modal analysis in time and frequency domain. Mech Syst Signal Process 165:108329

Perez-Sanjines F, Peeters C, Verstraeten T, Antoni J, Nowé A, Helsen J (2023) Fleet-based early fault detection of wind turbine gearboxes using physics-informed deep learning based on cyclic spectral coherence. Mech Syst Signal Process 185:109760

Kestel K, Peeters C, Antoni J, Sheng S, Helsen J (2022) Bearing fault detection on wind turbine gearbox vibrations using generalized likelihood ratio-based indicators (no. NREL/CP-5000-81777). National Renewable Energy Lab.(NREL), Golden

Peeters C, Antoni J, Gioia N, Guillaume P, Helsen J (2018) A novel multi-harmonic demodulation technique for instantaneous speed estimation. In: Conference on noise and vibration engineering

Peeters C, Verstraeten T, Nowé A, Helsen J (2019) Wind turbine planetary gear fault identification using statistical condition indicators and machine learning. In: International conference on offshore mechanics and arctic engineering, vol 58899. American Society of Mechanical Engineers,

Peeters C, Antoni J, Daems PJ, Helsen J (2020) Separation of vibration signal content using an improved discrete-random separation method. In: Separation of vibration signal content using an improved discrete-random separation method ISMA 2020, pp 1–9

Acknowledgements

This research was supported by funding from the Flemish Government under the “Onderzoeksprogramma Artificiële Intelligentie (AI) Vlaanderen” programme. The authors moreover acknowledge the financial support via theMaDurOS program from VLAIO (Flemish Agency for Innovation and Entrepreneurship) and SIM (Strategic Initiative Materials) through project SBO MaSiWEC (HBC.2017.0606) and SBO SeaFD (HBC.2019.0121). The authors would also like to acknowledge FWO (Fonds Wetenschappelijk Onderzoek) for their support through the junior postdoc grant of Cédric Peeters (#1282221N). The authors also acknowledge the support of De Blauwe Cluster through the project Supersized 4.0 (HBC.2019.0135).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

P.-J. Daems, C. Peeters, J. Matthys, T. Verstraeten and J. Helsen declare that they have no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Daems, PJ., Peeters, C., Matthys, J. et al. Fleet-wide analytics on field data targeting condition and lifetime aspects of wind turbine drivetrains. Forsch Ingenieurwes 87, 285–295 (2023). https://doi.org/10.1007/s10010-023-00643-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-023-00643-0