Abstract

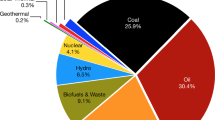

Over the last decades, the use of wind power as a source of renewable power has increased, while the Levelized Cost of Electricity (LCoE) of wind power has fallen. In order to further drive down the LCoE, there is an increasing interest to monitor key turbine quantities in order to improve maintenance procedures and decrease downtime. In this paper, we focus on the indirect detection of one such key quantity, the torque load on the gearbox. In order to avoid expensive direct torque sensors, we study the potential of strain gauges installed on the gearbox housing as virtual torque sensors. Our results verify that the strain response is repeatable, torque-driven and predictable; which are the most important conditions for using the sensors in virtual load sensing. Next, we compare the measured strain response to simulated strain results obtained from a physics-based model. The model consists of a static FE model of the gearbox housing and a torsional model of the shafts and gears in the drivetrain. An optimisation approach selects the FE model node where the simulated strain best matches the measured strain. We conclude that the studied strain gauges are promising for model-based virtual sensing of the torque on the gearbox.

Zusammenfassung

Im Lauf der letzten Jahrzehnte hat die Nutzung der Windkraft als Quelle erneuerbarer Energie zugenommen, während die Stromgestehungskosten („Levelized Cost of Electricity”, LCoE) der Windkraft gesunken sind. Um die LCoE weiter zu senken, besteht ein zunehmendes Interesse daran, wichtige Schlüsselgrößen der Windenergieanlagen zu überwachen, um die Wartungsverfahren zu verbessern und Ausfallzeiten zu verkürzen. In diesem Beitrag konzentrieren wir uns auf die indirekte Erfassung einer solchen Schlüsselgröße, der Drehmomentbelastung des Getriebes. Um teure direkt-messende Drehmomentsensoren zu vermeiden, untersuchen wir das Potenzial von Dehnungsmessstreifen (DMS), die auf dem Getriebegehäuse als virtuelle Drehmomentsensoren installiert sind. Unsere Ergebnisse bestätigen, dass das Dehnungssignal wiederholbar, drehmomentgesteuert und vorhersagbar ist; dies sind die wichtigsten Voraussetzungen für den Einsatz der DMS als virtuelle Drehmomentsensoren. Weiterhin vergleichen wir das gemessene Dehnungssignal mit simulierten Dehnungssignalen, die von einem physikalischen Modell stammen. Das Modell besteht aus einem statischen FE-Modell des Getriebegehäuses und einem Torsionsmodell der Wellen und Zahnräder im Antriebsstrang der Windenergieanlage. Ein Optimierungsansatz wählt denjenigen Knoten des FE-Modells aus, bei dem das simulierte Dehnungssignal am besten mit dem gemessenen übereinstimmt. Wir schließen daraus, dass die untersuchten DMS vielversprechend für die modellbasierte virtuelle Erfassung des Drehmoments am Getriebe sind.

Similar content being viewed by others

References

Eurostat (2022) Renewable energy on the rise: 37% of EU’s electricity. https://ec.europa.eu/eurostat/web/products-eurostat-news/-/ddn-20220126-1. Accessed 9 December 2022

(2019) A European Green Deal. https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en. Accessed 9 December 2022

IRENA (2020) Renewable Power Generation Costs in 2019. Tech. Rep., IRENA, Abu Dhabi. https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2018/Jan/IRENA_2017_Power_Costs_2018.pdf (arXiv:1011.1669v3.). Accessed 9 December 2022

Nejad AR et al (2022) Wind turbine drivetrains: state-of-the-art technologies and future development trends. Wind Energy Sci 7(1):387–411. https://doi.org/10.5194/wes-7-387-2022

Peeters J, Schmidt S, Verellen M, Desmet W, Pluymers B, Moens D, Neeckx S (eds) (2022) Empowering a sustainable future with continuous innovation in wind turbine powertrains. Proceedings of ISMA2022 International Conference on Noise and Vibration Engineering. KU Leuven, Leuven, pp 27–39

Turnbull A, McKinnon C, Carrol J, McDonald A (2022) On the development of offshore wind turbine technology: an assessment of reliability rates and fault detection methods in a changing market. Energies. https://doi.org/10.3390/en15093180

Carroll J, McDonald A, McMillan D (2016) Failure rate, repair time and unscheduled O&M cost analysis of offshore wind turbines. Wind Energy 19:1107–1119. https://doi.org/10.1002/we.1887

HBM T12HT – very high-capacity torque. https://www.hbm.com/en/6337/t12ht-high-capacity-torque-sensor. Accessed 17 October 2022

Cappelle C et al (2021) Sensor selection for cost-effective virtual torque measurements on a wind turbine gearbox. Forsch Ingenieurwes 85(2):325–334. https://doi.org/10.1007/s10010-021-00464-z

Forrier B, Naets F, Desmet W (2017) Broadband load torque estimation in mechatronic powertrains using nonlinear kalman filtering. IEEE Trans Ind Electron 65(3):2378–2387. https://doi.org/10.1109/TIE.2017.2739709

Perišić N, Kirkegaard PH, Pedersen BJ (2015) Cost-effective shaft torque observer for condition monitoring of wind turbines. Wind Energy 18:1–19

Mehlan FC, Nejad AR, Gao Z (2022) Digital twin based virtual sensor for online fatigue damage monitoring in offshore wind turbine drivetrains. J Offshore Mech Arct Eng 144:1–9. https://doi.org/10.1115/1.4055551

Azzam B, Schelenz R, Jacobs G (2022) Sensor screening methodology for virtually sensing transmission input loads of a wind turbine using machine learning techniques and drivetrain simulations. Sensors. https://doi.org/10.3390/s22103659

CWD Center for wind power drives. www.cwd.rwth-aachen.de. Accessed 13 October 2022

Azzam B, Schelenz R, Cardaun M, Jacobs G (2023) From simulations to accelerated testing: design of experiments for accelerated load testing of a wind turbine drivetrain based on aeroelastic multibody simulation data. Appl Sci 13(1):356. https://doi.org/10.3390/app13010356

Azzam B, Schelenz R, Jacobs G Development of a virtual sensor to estimate wind turbine gearbox input loads (Unpublished manuscript)

Bosmans J, Gallas S, Rocha de Melo Filho NG, Kirchner M, Desmet W (2022) Validation of wind turbine gearbox structural FE models through modal analysis at component and (sub-)assembly level. Proceedings of ISMA2022 International Conference on Noise and Vibration Engineering. Leuven, pp 4551–4565

Risaliti, E. Model based virtual sensors for wheel center loads and full strain field on vehicle suspension components. Ph.D. thesis, KU Leuven (2019).

Vanhollebeke, F. Dynamic Analysis of a Wind Turbine Gearbox Towards Prediction of Mechanical Tonalities. Ph.D. thesis, KU Leuven (2015).

Acknowledgements

This research is supported by the Flanders Innovation & Entrepreneurship Agency within the V6LoadS project in cooperation with the Center for Wind Power Drives and ZF Wind Power. The Center for Wind Power Drives is acknowledged for providing the measurement data considered in this paper, in the context of the joint V6LoadS project. Furthermore, the Research Fund KU Leuven is gratefully acknowledged for its support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bosmans, J., Kirchner, M., Croes, J. et al. Validation of a wind turbine gearbox strain simulation model in service to virtual sensing. Forsch Ingenieurwes 87, 107–117 (2023). https://doi.org/10.1007/s10010-023-00635-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-023-00635-0