Abstract

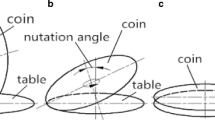

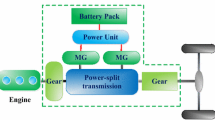

Since more attention has been paid to the development of pure electric vehicles, small and high efficiency of transmission system is the trend. The paper proposes a novel double-arc bevel gear nutation transmission system with two inputs and one output for pure electric vehicles. Compared with the traditional planetary gear transmission, the designed system has advantages of compact structure, small radial dimension and low cost. The nutation transmission of double-arc bevel gears is transformed into a spur planetary gear transmission mechanism with few teeth difference when the inclination angle is equal to zero. Based on kinetic and gear meshing analysis, it is found that the transmission efficiency of the model is related to the nutation gear ratio and the speed ratio of two power sources. The approach of analyzing the efficiency proposed in this paper can provide theoretical basis for the efficiency analysis of the nutation transmission in the future.

Zusammenfassung

Da der Entwicklung von reinen Elektrofahrzeugen mehr Aufmerksamkeit gewidmet wurde, ist der Trend bei der kleinen und hohen Effizienz des Übertragungssystems. Das Papier schlägt ein neuartiges Doppelbogen-Getriebe mit zwei Eingängen und einem Ausgang für reine Elektrofahrzeuge vor. Im Vergleich zur herkömmlichen Planetengetriebe hat das entworfene System Vorteile der kompakten Struktur, der geringen Radialgeschwindigkeit und der geringen Kosten. Die Nutverbindung von Doppelbogen-Kegelrädern wird in einen Stirnrüsten-Planetengetriebemechanismus mit wenigen Zahnunterschieden umgewandelt, wenn der Neigungswinkel gleich Null ist. Basierend auf der kinetischen und Zahnradmeshing-Analyse wird festgestellt, dass die Übertragungseffizienz des Modells mit dem Verzugsgetriebe-Verhältnis und dem Geschwindigkeitsverhältnis zweier Stromquellen zusammenhängt. Der Ansatz, die in diesem Papier vorgeschlagene Effizienz zu analysieren, kann theoretische Grundlagen für die Effizienzanalyse der Nutationsübertragung in der Zukunft liefern.

Similar content being viewed by others

Abbreviations

- \(d_{m}\) :

-

Pitch circle diameter of the midpoint of tooth width

- \(F_{n}\) :

-

Positive pressure

- \(F_{t}\) :

-

Tangential force

- \(F_{\tau }\) :

-

Radial force

- \(F_{x}\) :

-

Axial force

- \(i_{12}\) :

-

Ratio of components 1 and 2

- \(i_{12}^{3}\) \(i_{21}^{3}\) :

-

ratio of components 1 and 2 when \(-\omega _{3}\) is added to the mechanism

- \(i_{13}^{2}\) \(i_{31}^{2}\) :

-

Ratio of components 1 and 3 when \(-\omega _{2}\) is added to the mechanism

- \(i_{31}\) :

-

Ratio of components 3 and 1

- \(i_{32}\) :

-

Ratio of components 3 and 2

- \(i_{32}^{1}\) \(i_{23}^{1}\) :

-

Ratio of components 3 and 2 when \(-\omega _{1}\) is added to the mechanism

- P:

-

\(\mathrm{Z}_{2}/\mathrm{Z}_{1}\)

- \(P_{1}^{3}\) \(P_{2}^{3}\) :

-

Power of component 1, 2 when \(-\omega _{3}\) is added to the mechanism

- \(P_{i}(i=1,2,3)\) :

-

Power of component 1, 2, 3

- \(P_{\text{in}}\) :

-

Input power

- \(P_{\mathrm{loss}}\) :

-

Relative sliding loss power

- \(r_{1}\) \(r_{2}\) :

-

Pitch radius of spiral bevel gear pair

- \(r_{v1}\) \(r_{v2}\) :

-

Equivalent pitch radius of cylindrical gear pair

- \(T_{i}(i=1,2,3)\) :

-

Torque of component 1, 2, 3

- \(v_{t}\) :

-

Relative sliding velocity

- \(\mathrm{Z}_{1}\) \(\mathrm{Z}_{2}\) :

-

Tooth number of components 1, 2

- \(z_{v1}\) \(z_{v2}\) :

-

Equivalent teeth number

- \(\alpha _{n}\) :

-

Pressure angle of pitch circle

- \(\upbeta\) :

-

Tooth alignment pressure angle

- \(\updelta\) :

-

Pitch cone angle

- \(\eta\) :

-

Mechanical efficiency of the nutation gear drive

- \(\eta '\) :

-

Efficiency coefficient

- \(\eta ^{''}\) :

-

Loss coefficient

- \(\eta _{\text{total}}\) :

-

Total efficiency of the nutation transmission system

- \(\mu\) :

-

Friction coefficient

- \(\varphi _{1}\) \(\varphi _{2}\) :

-

Meshing power coefficient of component 1, 2

- \(\omega _{i}(i=1,2,3,5)\) :

-

Angular velocity of component 1,2,3,5

- \(\omega _{i}^{3}(i=1,2,5)\) :

-

Angular velocity of component 1, 2, 5 when \(-\omega _{3}\) is added to the mechanism

- \(\omega _{v1}\) \(\omega _{v2}\) :

-

Angular velocity of the equivalent gear pair

References

Husani I (2003) Electric and Hybrid Vehicles. CRC Press, Boca Raton, Florida

Miller M, Holmes A, Conlon B, Savagian P (2011) The GM “Voltec” 4ET50 multi-mode electric transaxle. Engines, vol 4. SAE, Int. J, pp 1102–1114

Mousavi MSR, Boulet B (2014) Modeling, simulation and control a seamless two-speed automated transmission for electric vehicles. in. American Control Conference, Portland, Oregon, USA, pp 3826–3831

Walker PD, Rahman AS, Zhu B (2015) Modelling, simulations, and optimization of electric vehicles for analysis of transmission ratio selection. Adv. Mech Eng 5:340435–340448

Roozegar M, Angeles J (2017) The optimal gear-shifting for a multi-speed transmission system for electric vehicles. Mech Mach Theory 116:1–13

Wu J, Liang J, Ruan J, Zhang N, Walker PD (2018) Efficiency comparison of electric vehicles powertrains with dual motor and single motor input. Mech Mach Theory 128:569–585

Holdstock T, Sorniotti A, Fracchia M, Bologna S, Bertolotto S (2012) Energy consumption analysis of a novel four-speed dual motor drivetrain for electric vehicles. in. Korea, vol 2012. IEEE, Vehicle Power and Propulsion Conference, Seoul, pp 295–300

Pennestrì E, Mariti L, Valentini PP, Mucino VH (2012) Efficiency evaluation of gearboxes for parallel hybrid vehicles: Theory and applications. Mech Mach Theory 49:157–176

Gupta AK, Ramanarayanan CP (2012) Analysis of circulating power within hybrid electric vehicle transmissions. Mech Mach Theory 49:157–176

Hu M, Zeng J, Xu S, Fu C, Qin D (2015) Efficiency study of a dual-motor coupling EV powertrain. Ieee Trans Veh Technol 64:2252–2260

Wang Y, Sun D (2014) Powertrain matching and optimization of dual-motor hybrid driving system for electric vehicle based on quantum genetic intelligent algorithm. Discret Dyn Nat Soc 2014:1–11

Urbina Coronado PD, Ahuett-Garza H (2014) Analysis of energy efficiency and driving range of electric vehicles equipped with a bimotor architecture propulsion system. Int J Electr Hybrid Veh 6:152–177

Urbina Coronado PD, Ahuett-Garza H (2015) Control strategy for power distribution in dual motor propulsion system for electric vehicles. Math Probl Eng 2015:1–10

Cai Y, Yao L, Xie Z, Zhang J, Peng C (2017) Influence analysis of system parameters on characteristics of the nutation drive with double circular arc spiral bevel gears. Forsch Ingenieurwes 81:125–133

Uzuka K, Enomoto I, Suzumori K (2009) Comparative assessment of several nutation motor types. Ieee/asme Trans Mechatronics 14:82–92

Yao L, Gu B, Haung S, Wei G, Dai JS (2010) Mathematical modeling and simulation of the external and internal double circular-arc spiral bevel gears for the nutation drive. J Mech Des 132(021008):1–10

Hong J, Yao L, Ji W, Huang Z (2015) Kinematic modeling for the nutation drive based on screw theory. Procedia CIRP 36:123–128

Huang D, Yao L, Li W, Zhang J (2017) Geometric modeling and torque analysis of the magnetic nutation gear drive. Forsch Ingenieurwes 81:101–108

Acknowledgements

The authors would like to acknowledge the support of the NSFC (Grant Nos. 51775114, 51275092 and 51875105), and Fujian Provincial Innovation Center for Robot Basic Components Technology and System Integration Manufacturing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wan, N., Yao, L. Efficiency modelling and analysis for a novel double-arc bevel gear nutation transmission system for pure electric vehicles. Forsch Ingenieurwes 83, 393–399 (2019). https://doi.org/10.1007/s10010-019-00359-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-019-00359-0