Abstract

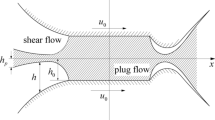

Considering surface roughness and non-equal cross-section feature of tapered body and non-Newtonian characters of grease, fresh grease lubrication problem at two tapered bodies contact in the initial lubrication stage was analyzed, and effects of profile crowning, misalignment (tilting and skewing), sliding and loads were included. The multigrid method was applied to grease lubrication simulation by linear interpolation of rough surfaces and the discrete convolution and FFT (DC-FFT) was employed to compute elastic deformation. The results show that grease film thickness decreases with sliding aggravation. Both surface roughness and tilting motion will weaken the effectiveness of crowning and deteriorate the film bearing capacity. The adaptability of the tapered body with the cut-off profile to tilting motion is better than that with the logarithmic profile. However, if the cut-off profile is adopted, the crowning radius at small end of the tapered body should be larger than that at large end. The effect of minor skewing on grease lubrication is relatively slight. In a wide range of speed, the variation of traction coefficient is similar to the typical Stribeck curve, and the contact would experience three states of full-film, mixed and boundary lubrication.

Zusammenfassung

Unter Berücksichtigung der Oberflächenrauheit und der ungleichen Querschnittsmerkmale des Kegelkörpers und der nicht-Newtonschen Merkmale des Schmierfetts wurde das Problem der Frischfettschmierung bei Kontakt zweier Kegelkörper in der Anfangsschmierungsphase analysiert und die Effekten vom Konturänderung, Fehlausrichtung (Kippen und Schräglauf), Rutschen und Lasten waren enthalten. Die Multigrid-Methode wurde auf die Schmierfettsimulation durch lineare Interpolation von rauen Oberflächen angewendet, und die diskrete Faltung und FFT (DC-FFT) wurden benutzt, um die elastische Verformung zu berechnen. Die Ergebnisse zeigen, dass die Fettfilmdicke mit zunehmender Verschlechterung des Rutschens abnimmt. Sowohl die Oberflächenrauheit als auch die Kippbewegung werden die Wirksamkeit des Konturänderungs schwächen und die Filmtragfähigkeit verschlechtern. Die Anpassungsfähigkeit des sich verjüngenden Körpers mit dem cut-off Profil an eine Kippbewegung ist besser als die mit dem logarithmischen Profil. Wenn jedoch das cut-off Profil übernommen wird, sollte der Balligkeitsradius am kleinen Ende des sich verjüngenden Körpers größer sein als am großen Ende. Der Effekt eines geringen Schräglaufs auf die Fettschmierung ist relativ gering. In einem weiten Geschwindigkeitsbereich ist die Variation des Traktionskoeffizienten der typischen Stribeck-Kurve ähnlich, und der Kontakt würde drei Zustände der Vollfilm-, Misch- und Grenzflächenschmierung erleben.

Similar content being viewed by others

References

Gerstenberger J, Poll G (2001) Rolling bearing lubrication with grease at low temperatures. Tribology 39:303–312

Gonzalez-Perez I, Roda-Casanova V, Fuentes A (2015) Modified geometry of spur gear drives for compensation of shaft deflections. Meccanica 50(7):1855–1867. https://doi.org/10.1007/s11012-015-0129-9

Deng S, Gu J, Cui Y et al (2017) Dynamic analysis of a tapered roller bearing. Ind Lubr Tribol 70(1):191–200

Hu YZ, Zhu D (2000) A full numerical solution to the mixed lubrication in point contacts. J Tribol 122(1):1–9

Noguchi S, Hotta T, Kanada T (2014) Development of tapered roller bearing with low torque: Reduction of sliding friction between large flange and roller end faces machined by precision powder shot peening. Proc Inst Mech Eng J J Eng Tribol 228(9):937–946

Lugt PM (2013) Grease lubrication in rolling bearings. John Wiley, West Sussex, UK

Rezasoltani A, Khonsari MM (2016) Mechanical degradation of lubricating grease in an EHL line contact. Tribol Int 109:541–551

Bujurke NM, Kantli MH, Shettar BM (2017) Jacobian free Newton–GMRES method for the solution of elastohydrodynamic grease lubrication in line contact using wavelet based pre–conditioners. Proc Natl Acad Sci India 4:1–19

Zhang C, Wang S, Zhang Y (2015) Pressure distribution analysis of elastohydrodynamic journal bearing under grease lubrication. In: International Conference on Fluid Power & Mechatronics, pp 74–79

Kauzlarich J, Greenwood JA (1972) Elastohydrodynamic lubrication with Herschel–Bulkley model greases. ASLE Trans 15(4):269–277

Yoo JG, Kim KW (1997) Numerical analysis of grease thermal elastohydrodynamic lubrication problems using the Herschel–Bulkley model. Tribol Int 30(6):401–408

Deng L, Ding M, Li GH et al (2009) Numerical analysis on elastohydrodynamic lubrication of automotive wheel bearings lubricated with grease. Lubr Eng 34(10):21–25 (In Chinese)

Liu MY, Zhu CC, Liu HJ (2014) A thermal EHL model for finite line contact with non-Newtonian fluids. Lubr Eng 39(2):48–55 (In Chinese)

Wen SZ, Ying TN (1988) A theoretical and experimental study of EHL lubricated with grease. J Tribol 110(1):38–43

Cheng J (1990) Elastohydrodynamic grease lubrication theory and numerical solution in line contacts. Lubr Eng 37(4):711–718

Jonkisz W, Krzeminski-Freda H (1982) The properties of elastohydrodynamic grease films. Wear 77(3):277–285

Hurley S, Cann PM (1999) Grease composition and film thickness in rolling contacts. NLGI Spokesman 63(4):12–22

Wang ZJ, Shen XJ, Chen XY et al (2018) Experimental investigation of EHD grease lubrication in finite line contacts. Friction 7(3):1–9. https://doi.org/10.1007/s40544-018-0208-8

Cann PM (2010) Grease lubrication of rolling element bearings—role of the grease thickener. Lubr Sci 19(3):183–196

Tong VC, Hong SW (2015) Characteristics of tapered roller bearings in relation to roller profiles. J Mech Sci Technol 29(7):2913–2919

Lundberg G (1939) Elastische berührung zweier halbräume. Forschung auf dem Gebiet des Ingenieurwesens 10(5):201–211

Zhu D, Ai XL (1997) Point contact EHL based on optically measured three-dimensional rough surfaces. J Tribol 119(3):375–384

Roelands CJA, Vlugter JC, Waterman HI (1963) The viscosity-temperature-pressure relationship of lubricating oils and its correlation with chemical constitution. J Fluids Eng 85(4):601–607

Liu S, Wang Q, Liu G (2000) A versatile method of discrete convolution and FFT (DC-FFT) for contact analyses. Wear 243(1–2):101–111

Hu YZ, Tonder K (1992) Simulation of 3‑D random rough surface by 2‑D digital filter and Fourier analysis. Int J Mach Tools Manuf 32(1):83–90

Dowson D (1992) Friction and traction in lubricated contacts. Fundamentals of friction: macroscopic and microscopic processes. Springer, Netherlands

Hamrock BJ, Jacobson BO (1984) Elastohydrodynamic lubrication of line contacts. ASLE Trans 27(4):275–287

Wymer DG, Cameron A (1974) Elastohydrodynamic lubrication of a line contact. ARCHIVE. Proc Inst Mech Eng 188:221–238

Dyson A, Wilson AR (1965) Paper 3: Film Thicknesses In Elastohydrodynamic Lubrication By Silicone Fluids. Proceedings of the Institution of Mechanical Engineers, Conference Proceedings 180(11):97–112. https://doi.org/10.1243/PIME_CONF_1965_180_323_02

Wen SZ, Huang P (2012) Principles of tribology. Tsinghua University Press, Beijing (In Chinese)

Lu X, Khonsari MM (2007) An experimental investigation of grease—lubricated journal bearings. J Tribol 129(1):84–90

Funding

The paper is supported by the National Natural Science Foundation of China (Grand No. 51675427).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Z. Wu, Y. Xu and K. Liu declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Wu, Z., Xu, Y. & Liu, K. The Analysis on Grease Lubrication at Two Tapered Bodies Contact Considering Surface Roughness. Forsch Ingenieurwes 83, 339–350 (2019). https://doi.org/10.1007/s10010-019-00350-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-019-00350-9