Abstract

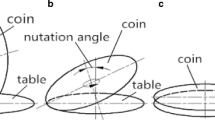

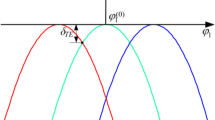

As a new type of gear transmission, nutation gear drive is extensively applied in aviation, ship, medical equipment and other fields. In this paper, a two-stage nutation drive mechanism of double circular arc (DCA) bevel gears is presented and its dynamic characteristics are studied. First, according to the principle of meshing transmission, a mathematical model of dynamic transmission error (DTE) based on assembly errors is established. Through the analysis of dynamic transmission characteristics, the DTE curves with assembly errors and varying load are obtained, and the simulation results are analyzed reasonably by using RMS evaluating indicator. Finally, through the test verification under different loads, it is concluded that in a reasonable loading range, the decrease of load will reduce the fluctuation range of transmission error. The reduction of transmission error fluctuation indicates that the nutation drive of DCA spiral bevel gears is more stable and the noise is reduced under low load conditions. The study of the dynamic characteristics will provide theoretical basis and practical reference for the design of DCA spiral bevel gears.

Zusammenfassung

Als neuartiger Getriebetyp wird das Nutationsgetriebe in der Luftfahrt, auf Schiffen, in medizinischen Geräten und in anderen Bereichen in großem Umfang eingesetzt. In dieser Arbeit wird ein zweistufiger Nutationsantrieb für Doppelkegelräder mit Kreisbogen (DCA) vorgestellt und seine dynamischen Eigenschaften untersucht. Zunächst wird nach dem Prinzip der vermaschten Übertragung ein mathematisches Modell des dynamischen Übertragungsfehlers (Dynamic Transmission Error, DTE) auf der Grundlage von Montagefehlern erstellt. Durch die Analyse der dynamischen Übertragungseigenschaften werden die DTE-Kurven mit Montagefehlern und variierender Last erhalten und die Simulationsergebnisse werden unter Verwendung des RMS-Bewertungsindikators angemessen analysiert. Schließlich wird durch die Prüfung unter verschiedenen Belastungen der Schluss gezogen, dass in einem angemessenen Belastungsbereich die Abnahme der Belastung den Schwankungsbereich des Übertragungsfehlers verringert. Die Verringerung der Übertragungsfehlerschwankung zeigt, dass der Nutationsantrieb von DCA-Spiralkegelrädern stabiler ist und das Geräusch unter Bedingungen geringer Last verringert wird. Die Untersuchung der dynamischen Eigenschaften liefert theoretische Grundlagen und praktische Hinweise für die Konstruktion von DCA-Spiralkegelrädern.

Similar content being viewed by others

References

Wei J, Gao P, Hu X et al (2014) Effects of dynamic transmission errors and vibration stability in helical gears. J Mech Sci Technol 28(6):2253–2262

Chen S, Tang J, Wu L (2014) Dynamics analysis of a crowned gear transmission system with impact damping: based on experimental transmission error. Mech Mach Theory 74:354–369

Zhu B, Qin W, Sun W et al (2011) Dynamic revolution and transmission error analysis of 2K-V cycloidal-pin planetary gear speed reducer. J Mech Transm 35(4):12–15

Yuan B, Chang S, Liu G et al (2019) Quasi-static analysis based on generalized loaded static transmission error and dynamic investigation of wide-faced cylindrical geared rotor systems. Mech Mach Theory 134:74–94

Karagiannis I, Theodossiades S (2013) An alternative formulation of the dynamic transmission error to study the oscillations of automotive hypoid gears. J Vib Acoust 136(1):11001–11012

Doğan O, Karpat F (2019) Crack detection for spur gears with asymmetric teeth based on the dynamic transmission error. Mech Mach Theory 133:417–431

Yang JJ, Shi ZH, Zhang H et al (2018) Dynamic analysis of spiral bevel and hypoid gears with high-order transmission errors. J Sound Vib 417:149–164

Hotait MA, Kahraman A (2013) Experiments on the relationship between the dynamic transmission error and the dynamic stress factor of spur gear pairs. Mech Mach Theory 70:116–128

Liu GZ, Shi WK, Chen ZY (2018) Finite element analysis of transmission error for hypoid gears considering installation error. J Jilin Univ (Eng Technol Ed) 48(4):984–989

Wu HP, Liu L (2018) Transmission error analysis of novel torus-involute gears based on ABAQUS. Mach Build Autom 47(3):115–118

Besharati SR, Dabbagh V, Amini H et al (2015) Nonlinear dynamic analysis of a new antibacklash gear mechanism design for reducing dynamic transmission error. J Mech Des N Y 137(5):54502–54503

Zhang ST, Wu FL, Zhang DH (2013) Analysis of effect of helix angle errors on gear drive of quasi-transverse-circular-arc gear. J Mech Transm 37(4):101–103, 109

Cho S, Choi J, Choi JH et al (2015) Numerical estimation of dynamic transmission error of gear by using quasi-flexible-body modeling method. J Mech Sci Technol 29(7):2713–2719

Sainte-Marie N, Velex P, Roulois G et al (2013) A study on the correlation between dynamic transmission error and dynamic tooth loads in spur and helical gears. ASME. J Vib Acoust 139(1):11001–11010

Velex P, Chapron M, Fakhfakh H et al (2016) On transmission errors and profile modifications minimising dynamic tooth loads in multi-mesh gears. J Sound Vib 379:28–52

Wang GJ, Chen L, Yu L et al (2017) Research on the dynamic transmission error of a spur gear pair with eccentricities by finite element method. Mech Mach Theory 109:1–13

Yao LG, Gu B, Huang SJ et al (2010) Mathematical modeling and simulation of the external and internal double circular-arc spiral bevel gears for the nutation drive. J Mech Des N Y 132(2):021008.1–2100810

Cai YW, Yao LG, Zhang J et al (2019) Feasibility analysis of using a two-stage nutation drive as joint reducer for industrial robots. J Mech Sci Technol 33(4):1799–1807

Cai YW, Yao LG, Xie ZY et al (2017) Influence analysis of system parameters on characteristics of the nutation drive with double circular arc spiral bevel gears. Forsch Ingenieurwes 81(2):125–133

Acknowledgements

The authors would like to acknowledge the support of the NSFC (Grant Nos. 51775114, 51275092 and 51875105), Fujian Provincial Industrial Robot Basic Components Technology Research and Development Center (Grant No. 2014H21010011), and Fujian Provincial Collaborative Innovation Center for High-end Equipment Manufacturing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cai, Y., Yao, L., Ding, J. et al. Study on transmission error of double circular arc spiral bevel gears for nutation drive based on assembly errors and different loads. Forsch Ingenieurwes 83, 481–490 (2019). https://doi.org/10.1007/s10010-019-00347-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-019-00347-4