Abstract

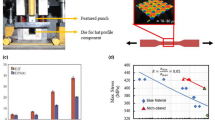

Gearwheels in automotive applications are usually designed as monolithic parts. Adapting the concept of multi-component design to those applications allows to reduce the car’s weight. The presented multi-component gearwheels consist of three pieces: a gear ring including teeth, a shaft and a wheel body that connects shaft and gear ring. Two gearwheel concepts as well as the corresponding joining strategy of gear ring and wheel body are introduced in this paper. First manufacturing concept is about the wheel body stapled by fine blanked sheet metal layers. Gear ring and wheel body are joined by a press fit. The second concept focuses on manufacturing the wheel body by lateral extrusion of a metal disk. Using the gear ring as the die in the forging tool allows manufacturing the wheel body as well as joining wheel body and gear ring simultaneously. The authors investigate both production processes virtually and compare both gearwheels designs regarding load and lightweight potential.

Similar content being viewed by others

References

Severin F (2014) Massiver Leichtbau. Potenziale massivumgeformter Komponenten. Industrieverband Massivumformung e. V, Hagen

Niemann G, Winter H, Höhn B‑R (2005) Konstruktion und Berechnung von Verbindungen, Lagern, Wellen. Maschinenelemente, vol. 1.

Hörmann F (2008) Einfluss der Prozessparameter auf einstufige Scherschneidverfahren zum Ausschneiden mit endkonturnaher Form. Technische Universität München. utg-Forschungsberichte, vol. 46. Hieronymus, München

Meissner R, Benkert T, Liewald M, Volk W (2017) Lightweight gearwheel design using separate gear ring and wheel body. Part II: Different manufacturing concepts for replacing a full body gearwheel. Steels in Cars and Trucks 2017, Proceedings

Mattheck C (2010) Denkwerkzeuge nach der Natur. Karlsruher Inst. für Technologie – Campus Nord, Karlsruhe

Meissner R, Liewald M (2016) Numerical investigations of multicomponent process lightweight design for joining gearwheels by lateral extrusion. MATEC Web Conf 80:13005

Meissner R, Liewald M (2016) Verfahrenskonzept zur umformtechnischen Herstellung von gebauten Zahnrädern im Mehrkomponentenverfahren mittels Quer-Fließpressen. 7. VDI-Fachtagung Welle-Nabe-Verbindungen. Gestaltung – Fertigung – Anwendungen. VDI-Berichte, vol. 2287. VDI-Verlag, Düsseldorf

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meissner, R., Benkert, T., Hiller, M. et al. Manufacturing processes of multi-component gearwheels. Forsch Ingenieurwes 81, 265–269 (2017). https://doi.org/10.1007/s10010-017-0249-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-017-0249-6