Abstract

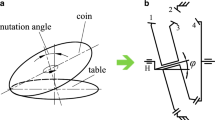

Gear transmission systems are one of the most frequently used systems for power transmission. The characteristics of a gear transmission system have important guiding significance in the design, manufacture and application of transmissions. This paper focuses on the influence of system parameters on the characteristics of a specific type of gear transmission, the nutation drive with double circular arc spiral bevel gears. Based on the transmission ratio analysis of single-stage and two-stage nutation drive systems, the system parameters, including nutation angle, gear spiral angle, pitch angle and cone distance, were defined. An analysis of the influence of system parameters on transmission efficiency was performed. Furthermore, the influence of system parameters on axial misalignment and cone displacement error was investigated. Finally, by changing the input frequency, input load, nutation angle, and spiral angle, variation regularity of the dynamic meshing force was obtained. A transmission performance analysis based on the influence of system parameters was achieved and provides the theoretical basis for better design of the nutation drive with double circular arc spiral bevel gear.

Similar content being viewed by others

References

Hsieh SP, Hwang TS, Ni CW (2009) Twin-VCM controller design for the nutator system with evolutionary algorithms. IETE Technical Review (Institution of Electronics and Telecommunication Engineers, India) 26(4):290–302

Uzuka K, Enomoto I, Suzumori K (2009) Comparative assessment of several nutation motor types. Ieee/asme Trans Mechatronics 14(1):82–92

He SJ (2007) Theory research on output mechanism of conical roller in nutation gear. Coal Mine Mach 28(2):55–57

Kemper Y (1981) The nutating traction drive. J Eng Power 103(1):154–158

Maroth AM, Riede U (1973) Nutation drive: a high-ratio power transmission. Mech Eng 95(2):30–34

Elu P, Kemper Y (1980) Performance of a nutating traction drive. American Society of Mechanical Engineers (Paper). 1980(80-C2/DET-63):50–56

Uzuka K, Enomoto I, Suzumori K (2006) Development of nutation motors (1st report, driving principle and basic characteristics of pneumatic nutation motor). Trans Japan Soc Mech Eng 72(4):1194–1199

Uzuka K, Enomoto I, Suzumori K (2007) Development of nutation motors (4th report, development of small-sized and high torque pneumatic nutation motor by the OFW type bevel gears and principle of lever). Trans Japan Soc Mech Eng 73(6):1731–1737

Oda S, Suzumori K, Uzuka K et al (2010) Development of nutation motors (improvement of pneumatic nutation motor by optimizing diaphragm design). Journal of Mechanical Science and Technology 24(1):25–28

Saribay ZB, Bill RC (2013) Design analysis of pericyclic mechanical transmission system. Mech Mach Theory 61(1):102–122

Green I (2008) On the kinematics and kinetics of mechanical seals, rotors, and wobbling bodies. Mech Mach Theory 43(7):909–917

Wang GX, Zhu LL, Wan ZY et al Electromechanical integrated nutation movable teeth transmission device. Chin Pat 102594016:2012-07-18

Wang GX, He WJ et al (2016) Analysis of the contact strength of the tooth face on the central disk of the nutation tooth. J Dalian Jiaotong University 37(2):32–37

Gu B, Yao LG et al (2006) The analysis and modeling for nutation drives with double circular-arc helical bevel gears. Material Sci Forum 505:949–954

Cai YJ, Yao LG et al (2007) Kinematics and dynamics simulation of nutation drive of double circular arc spiral bevel gear. Transm Technol 21(4):22–26

Yao LG, Gu B et al (2010) Mathematical modeling and simulation of the external and internal double circular-arc spiral bevel gears for the nutation drive. Journal of Mechanical Design, ASME 132(2):021008.1–10

Lin Z, Yao LG (2013) Mathematical model and 3d modeling of involute spiral bevel gears for nutation drive. Adv Mat Res 697:503–506

Lin Z, Yao LG et al (2014) Contact trace of internal meshing double circular-arc spiral bevel gears. Adv Mat Res 945:822–825

Zhang J, Yao LG et al (2015) Tooth profile accurate modeling of internal and external double circular-arc spiral bevel gears. Modern Manufacturing Engineering 0(1):119–124. doi:10.16731/j.cnki.1671-3133.2015.01.013

Hong JL, Yao LG et al (2015) Kinematic modeling for the nutation drive based on screw theory. Procedia Cirp 36:123–128

Litvin FL, Kuan C, Wang JC et al (1993) Minmization of deviation of gear real tooth surfaces determined by coordinate measurements. J Mech Des Asme 115(4):995–1001

Simon V (2008) Influence of tooth errors and misalignments on tooth contact in spiral bevel gears. Mech Mach Theory 43(10):1253–1267

Li J (2007) Design and dynamic simulation research of the planetary gear transmission with axial series less teeth difference. Master Degree Thesis Chongqing University. doi:10.7666/d.y1139230

Yao JC, Chen YB et al (2001) Study on calculation method of meshing efficiency of gear transmission. Chin J Mech Eng 37(11):18–21

Ming XZ, Li MD et al (2014) The establishment and analysis of the gear surface equation with error surface based on multi body system theory. Mech Drive 38(11):1–4

Wang ZH, Yu J et al (2014) Analysis of the influence of installation errors on the contact trace of spiral bevel gears. Mech Transm 38(2):21–24

Li JH, Wang Q et al (2014) Gear tooth contact analysis considering the error. Mech Drive 38(3):133–136

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cai, Y., Yao, L., Xie, Z. et al. Influence analysis of system parameters on characteristics of the nutation drive with double circular arc spiral bevel gears. Forsch Ingenieurwes 81, 125–133 (2017). https://doi.org/10.1007/s10010-017-0245-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-017-0245-x