Abstract

The topic of this study is to investigate the load-dependent losses of practical spur gears, for which the existing calculation method is analyzed in detail and improved.

In drive technology, spur gears are frequently used for the transformation of torque and speed. Power transmission always involves power losses. Thereby, particular interest has to be given to the load-dependent gear loss as it often accounts for a large share of the total loss.

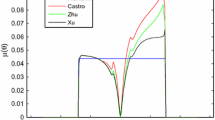

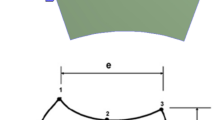

According to the state of the art, the calculation of load-dependent gear loss is mainly based on (i) gear loss factors derived from simplified load distributions and (ii) a mean coefficient of friction derived from empirical equations based on spur gears without flank modifications. In practice, however, helical gears for improved NVH (Noise-Vibration-Harshness) behavior and flank modifications for uniform contact patterns are used. The modified mesh and contact conditions of modified helical gears affect the load-dependent gear losses significantly. Hence, significant deviations compared to the state of the art can occur.

Comprehensive experimental investigations at the FZG efficiency test rig and FZG Bearing power loss test rig have been carried out to investigate the load-dependent gear losses of modified helical gears. The results are used to improve an existing calculation method that distinguishes between geometrical and tribological influence factors. Thereby, the local mesh and contact conditions along the plane of action are considered by the gear loss factor HVL according to Wimmer, whereas the calculation of the mean coefficient of friction µmz has been enhanced by regression analyses. A comparison of the improved calculation method to the state of the art shows improved accuracy for determining the load-dependent gear losses and hence the efficiency of gear boxes.

Similar content being viewed by others

Notes

Subscript “686” according to number of the FVA-Research Project: FVA-No. 686/I.

References

Bair S, Winer WO (1979) A rheological model for elastohydrodynamic contacts based on primary laboratory data. ASME J Lubr Technol 101:258–265

Diab Y, Ville F, Velex P (2006) Prediction of power losses due to tooth friction in gears. Tribol Trans 49(2):260–270

Doleschel A (2002) Wirkungsgradberechnung von Zahnradgetrieben in Abhängigkeit vom Schmierstoff. Dissertation, Technical University of Munich

Doleschel A, Michaelis K, Höhn B‑R (2009) Lubricant influence on gear efficiency. Proc. of the ASME Int. Design Engineering Techn. Conf., San Diego.

Ertel-Mohrenstein A (1984) Die Berechnung der hydrodynamischen Schmierung gekrümmter Oberflächen unter hoher Belastung und Relativbewegung. VDI Fortschrittsbericht, Reihe 1, vol. 115.

Eyring H (1936) Viscosity, plasticity, and diffusion as examples of absolute reaction rates. J Chem Phys 4(4):283–291

Fernandes CMCG, Marques P, Martins R, Seabra J (2015) Gearbox power loss. Part II: friction losses in gears. Tribol Int. doi:10.1016/j.triboint.2014.12.004

Grubin AN, Vinogradova JE (1949) Investigation of Contact Maschine Components. Cent. Sci. Res. Tech. Mech. Eng, Moskau. (Book No. 30)

Hepermann P, Beilicke R, Bartel D, Tenberge P, Deters L (2012) FVA-Nr. 598/I – Heft 1024 – Örtliche Fresstragfähigkeit. Forschungsvereinigung Antriebstechnik e. V., Frankfurt am Main

Hinterstoißer M (2013) Zur Optimierung des Wirkungsgrades von Stirnradgetrieben. Dissertation, Technical University of Munich

ISO 14635-1, 2000-06 (2000) FZG test method A/8.3/90 for relative scuffing load-carrying capacity of oils.

Jurkschat T, Otto M, Stahl K (2015) FVA – Nr. 364/IV – Heft 1145 – Erweiterung von LAGER2 zur Dimensionierung von Wälzlagern in Industriegetrieben: Verlustleistung und Betriebstemperatur. Forschungsvereinigung Antriebstechnik e. V., Frankfurt am Main

Jurkschat T, Lohner T, Stemplinger J‑P, Stahl K (2017) IGF Nr. 17151 N1, FVA-Nr. 686 – Verlustleistung von Stirnradverzahnungen. Forschungsvereinigung Antriebstechnik e. V., Frankfurt am Main

Lohner T, Mayer J, Michaelis K, Höhn B‑R, Stahl K (2017) On the running – in behavior of lubricated line contacts. J Eng Tribol 231(4):441–452. doi:10.1177/1350650115574869

Mayer J (2013) Einfluss der Oberfläche und des Schmierstoffs auf das Reibungsverhalten im EHD-Kontakt. Dissertation, Technical University of Munich

Ohlendorf H (1958) Verlustleistung und Erwärmung von Stirnrädern. Dissertation, Technical University of Munich

Schlenk L (1995) Untersuchungen zur Freßtragfähigkeit von Großzahnrädern. Dissertation, Technical University of Munich

Sheng L, Vaidyanathan A, Harianto J, Kahraman A (2009) Influence of design parameters on mechanical power losses of helical gear pairs. J Adv Mech Des Syst Manuf 3(2):146–158

SKF (1994) Hauptkatalog: Katalog 4000/IV T. Schweinfurt

Stiller S, Otto M, Stahl K (2014) FVA-Nr. 30VII – Heft 1077 – RIKOR J. Erweiterung Ritzelkorrekturprogramm (RIKOR) zur Bestimmung der Lastverteilung von Stirnradgetrieben. Forschungsvereinigung Antriebstechnik e. V., Frankfurt am Main

Velex P, Ville F (2009) An analytical approach to tooth friction losses in spur and helical gears-influence of profile modifications. J Mech Des. doi:10.1115/1.3179156 (Transactions of the ASME)

Wimmer A (2006) Lastverluste von Stirnradverzahnungen. Dissertation, Technical University of Munich

Ziegltrum A, Lohner T, Stahl K (2016) TEHL simulation on the influence of lubricants on load-dependent gear losses. Tribol Int. doi:10.1016/j.triboint.2016.12.018

Acknowledgements

The presented work was sponsored by the “Arbeitsgemeinschaft industrieller Forschungsvereinigung e. V. (AiF)”, with funding from the “Bundesministerium für Wirtschaft (BMWi, IGF no. 17151 N/1)” and with an equity ratio from the “Forschungsvereinigung Antriebstechnik e. V. (FVA)”. The results shown in this work were taken from results of the research project FVA 686/I. More detailed information is provided in the final report. Special gratitude is owed to the active members of the attendant working team for the joint research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jurkschat, T., Lohner, T. & Stahl, K. Improved calculation method for load-dependent gear losses. Forsch Ingenieurwes 81, 109–115 (2017). https://doi.org/10.1007/s10010-017-0231-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-017-0231-3