Abstract

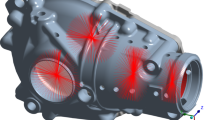

High load carrying capacity in the gear mesh can be achieved when the contact load is well distributed. Designing an adequate tooth flank geometry requires a thorough calculation approach. This is particularly important for automotive hypoid gearboxes with aluminum housing. In this paper, the deformation analysis of housing, bearings and shafts for a hypoid gearbox is validated by measurements at a static test rig. The challenge of compensating friction effects to get high-quality measurement results is successfully met by the presented approach.

There are several computer programs to calculate the elastic deformation behavior of the system shaft-bearing-housing. Most of the calculation programs use analytical approaches. The advantage of these programs, in comparison to a full FEM approach, is an efficient parameterization of gears and a very short calculation time, while delivering high precision results. The deformation behavior of housings can be considered in different ways. The deformation behavior of a bearing seat can be modelled by its stiffnesses. For housings with lower stiffnesses (for example aluminum housings), crossover influences become more and more important. The deformation behavior of a housing can be taken into account by a stiffness matrix. The stiffness matrix of a housing can be determined by using the finite elements method. Therefore, the complex elastic deformation behavior of housings can be considered in analytical calculation approaches. Within the scope of a research project, investigations have been made to validate the calculated elastic deformations of the shaft-bearing-housing system. For this purpose, deformation measurements of a test gearbox were taken by using a 3D coordinate measuring machine. The test gearbox is static and consists of a hypoid gearbox for automotive applications. The input torque is provided by a lever mechanism. The elastic deformation of the test gear box has been measured and compared to calculation results. Therefore, different approaches of modelling the elastic deformation behavior of the housing can be validated and compared to each other.

Similar content being viewed by others

References

Coleman W (1975) Analysis of mounting deflections on bevel and hypoid gears. SAE technical paper series. doi:10.4271/750152

Xu H (2009) Effects of axle deflection and tooth flank modification on hypoid gear stress distribution and contact fatigue life. Gear Technol 8:39–46

Choi B‑J, Yoon J‑H, Oh J‑E (2012) A study on axle gear whine noise reduction with deflection test. Proc Inst Mech Eng D J Automob Eng 226:225–233

Yoon J‑H, Choi B‑J, Yang I‑H, Oh J‑E (2011) Deflection test and transmission error measurement to identify hypoid gear whine noise. Int J Automot Technol 12(1):59–66

James B, Douglas M, Palmer D (2002) Predicting the contact conditions for hypoid gear sets by analysis and a comparison with test data. SAE Trans J Passeng Cars 2002:1489–1494

Weidner G, Jäckle M, Lechner G (1994) Verformungsmessung an Fahrzeuggetrieben auf einem Koordinatenmeßgerät. Antriebstechnik 33(1–2):47–50

Jäckle M (2001) Untersuchungen zur elastischen Verformung von Fahrzeuggetrieben. Habilitationsschrift, Universität Stuttgart

Neubauer B, Weinberger U (2016) FVA-Nr. 571/II – Heft 1197 – Berechnung der Lastverteilung in Getriebesystemen mit beliebig angeordneten Planetenradstufen. Forschungsvereinigung Antriebstechnik e. V., Frankfurt a. M.

Curtis S, Pears J, Palmer D, Eccles M, Poon A, Moon-Gon K, Geum-Yong J, Jong-Kuk K, Sang-Hoon J (2005) An analytical method to reduce gear whine noise, including validation with test data. SAE Trans J Passeng Cars 2005:2195–2202

James B, Douglas M (2002) Development of a gear whine model for the complete transmission system. SAE Trans J Passeng Cars 2002:1065–1074

James B, Harris O (2002) Predicting unequal planetary load sharing due to manufacturing errors and system deflections, with validation against test data. SAE Trans J Passeng Cars 2002:1057–1064

Pears J, Curtis S, Poon A, Smith A, Poon D, Palmer D (2005) Investigation of methods to predict parallel and epicyclic gear transmission error. SAE Trans J Passeng Cars 2005:2186–2194

Smith A, Pears J, Platten M, Palmer D (2007) Epicyclic gear transmission error – the importance of controlling tolerances. SAE Trans J Passeng Cars 2007:1763–1770

Weinberger U, Glenk C (2017) FVA-Nr. 711 – Heft (vor Drucklegung) – Einbindung elastischer Gehäusestrukturen in die Getriebeauslegung mit RIKOR und Visualisierung des Getriebegesamtsystems in der FVA-Workbench. Forschungsvereinigung Antriebstechnik e. V., Frankfurt a. M.

Klingelnberg J (2008) Kegelräder. Grundlagen, Anwendungen. Springer, Heidelberg

Acknowledgements

The authors would like to thank the Forschungsvereinigung Antriebstechnik e. V. and the working groups “AK Berechnung und Simulation” and “AG RIKOR” for the financing and support of this research project.

Funding

The contents of this publication are based on a research project, supported by the Forschungsvereinigung Antriebstechnik e. V. (FVA-Nr. 592 II “Weiterführende Validierung der Verformungsrechnung in RIKOR – Detaillierte Betrachtung einzelner Getriebeelemente”).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Daffner, M., Otto, M. & Stahl, K. Elastic deformation of a hypoid gearbox. Forsch Ingenieurwes 81, 215–220 (2017). https://doi.org/10.1007/s10010-017-0216-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-017-0216-2