Abstract

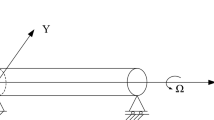

The paper presents an elastic multiple-mass model for rotordynamic analysis of flexible electrical rotors supported in sleeve bearings, considering mechanical unbalances and electromagnetic forces. This model has been especially developed for flexible electrical rotors, which operate near below or near above the first critical bending speed of the rotor. Using this simplified model, a static rotor active part eccentricity can be simulated and the orbital movement of the rotor can be calculated. Additionally, the influence of different balancing concepts—elastic balancing versus rigid balancing—on the shaft vibrations is analyzed. To verify the model, a finite element analysis was performed, which indicates a satisfactory match. On the one hand, the aim of the paper is to derive an elastic multiple-mass model for rotordynamic analysis of flexible electrical rotors for special boundary conditions. On the other hand, the aim is to show the mathematical coherences—based on a simplified model—between the rotordynamics, the oil film characteristics of the sleeve bearings, the elasticity of the rotor structure, the electromagnetics and the balancing concept.

Zusammenfassung

Der Beitrag beschreibt ein elastisches Mehrmassenmodell zur rotordynamischen Analyse von flexiblen Elektrorotoren mit Gleitlagern, unter der Berücksichtigung von Unwuchten und magnetischen Kräften. Das Modell wurde speziell entwickelt für flexible, elektrische Rotoren, die nahe unterhalb oder nahe oberhalb der ersten biegekritischen Drehzahl des Rotors betrieben werden. Mit diesem simplifizierten Modell kann eine statische Exzentrizität des Rotoraktivteils simuliert und die Orbitbewegungen des Rotors berechnet werden. Zusätzlich wird der Einfluss verschiedener Wuchtkonzepte – elastisches Wuchten gegenüber starrem Wuchten – untersucht. Um das Mehrmassenmodell zu verifizieren wurde eine Finite-Element Analyse durchgeführt und eine zufriedenstellende Übereinstimmung erreicht. Die Zielstellung dieses Beitrags ist es einerseits ein vereinfachtes Mehrmassenmodell für bestimmte Randbedingungen zur rotordynamischen Analyse von flexiblen Elektrorotoren herzuleiten. Andererseits sollen die mathematischen Zusammenhänge – basierend auf einem einfachen Modell – zwischen der Rotordynamik, den Ölfilmeigenschaften der Gleitlager, der Rotorstrukturelastizität, der Elektromagnetik und dem Wuchtkonzepte aufgezeigt werden.

Similar content being viewed by others

Abbreviations

- a n :

-

Semi-major axis of the orbit (m)

- b n :

-

Semi-minor axis of the orbit (m)

- c a,g,i :

-

Stiffness coefficients of the anti-friction bearing (kg/s2)

- c m :

-

Electromagnetic stiffness (kg/s2)

- c f,g,ij :

-

Stiffness coefficients of the oil film (kg/s2)

- c nk,ij :

-

Stiffness coefficients of the system (kg/s2)

- c r,nk :

-

Stiffness coefficients of the rotor structure (kg/s2)

- c s,g,i :

-

Stiffness coefficients of the support of the balancing machine (kg/s2)

- d f,g,ij :

-

Damping coefficients of the oil film (kg/s)

- d s,g,i :

-

Damping coefficients of the support of the balancing machine (kg/s)

- e m :

-

Electromagnetic eccentricity of the rotor active part (m)

- e u :

-

Static mass eccentricity of the rotor active part (m)

- F m :

-

Magnetic force (N)

- F k :

-

Static force (N)

- F b,g,i :

-

Bearing forces (N)

- l :

-

Length (m)

- m n :

-

Lumped masses of the rotor model (kg)

- m u :

-

Mass of the rotor active part (kg)

- m ∑ :

-

Mass of the whole rotor (kg)

- \(\underline{r}_{n}\) :

-

Complex vector (m)

- U k :

-

Unbalance (kgm)

- w n :

-

Displacement (m)

- z;y :

-

Coordinates (m)

- A b :

-

Flexible matrix for rigid rotor structure (s2/kg)

- A r :

-

Flexible matrix of the rotor structure (s2/kg)

- C :

-

Stiffness matrix of the system (kg/s2)

- C a,g :

-

Stiffness matrix of the anti-friction bearing (kg/s2)

- C f,g :

-

Stiffness matrix of the oil film (kg/s2)

- C m :

-

Electromagnetic stiffness matrix (kg/s2)

- C s,g :

-

Stiffness matrix of the support of the balancing machine (kg/s2)

- D :

-

Damping matrix of the system (kg/s)

- D a,g :

-

Damping matrix of the antifriction bearing (kg/s)

- D f,g :

-

Damping matrix of the oil film (kg/s)

- D s,g :

-

Damping matrix of the support of the balancing machine (kg/s)

- f :

-

Excitation vector (N)

- M :

-

Mass matrix of the system (kg)

- q;w :

-

Coordinate vector (m)

- α :

-

Real part of the complex eigenvalue (1/s)

- α b,nk,ij :

-

Flexibility coefficients for rigid rotor structure (s2/kg)

- α f,g,ij :

-

Flexibility coefficients of the oil film (s2/kg)

- α r,nk :

-

Flexibility coefficients of the rotor structure (s2/kg)

- β k ;β m :

-

Phase (rad)

- η :

-

Factor for ideal balancing (–)

- \(\underline{\lambda}\) :

-

Complex eigenvalue (1/s)

- ω :

-

Natural angular frequency (1/s)

- Ω :

-

Rotor angular frequency (1/s)

- ψ n :

-

Angle of the semi-major axis of the orbit (rad)

References

IEC 60034-14 (2007) Rotating electrical machines—Part 14: Mechanical vibration of certain machines with shaft heights 56 mm and higher—Measurement, evaluation and limits of vibration severity. International Electrotechnical Commission

ISO 10816-3 (2009) Mechanical vibration—Evaluation of machine vibration by measurements on non-rotating parts—Part 3: Industrial machines with nominal power above 15 kW and nominal speeds between 120 r/min and 15 000 r/min when measured in situ. International Organization for Standardization

ISO 7919-3 (2009) Mechanical vibration—Evaluation of machine vibration by measurements on rotating shafts—Part 3: Coupled industrial machines. International Organization for Standardization

API 541 (2004) Form-wound-Squirrel-Cage Induction Motors-500 Horse power and Larger. American National Standard Institute/American Petrol Institute

ISO 1940-1 (2003) Mechanical vibration—Balance quality requirements for rotors in a constant (rigid) state—Part 1: Specification and verification of balance tolerances. International Organization for Standardization

ISO 11342 (1998) Mechanical vibration—Methods and criteria for the mechanical balancing of flexible rotors. International Organization for Standardization

Kellenberger W (1987) Elastisches Wuchten. Springer, Berlin

Kellenberger W (1974) Limits to modal balancing of flexible rotors. In: IUTAM symp dynamics of rotors, Lybgby, Denmark. Springer, Berlin, pp 206–243

Gosiewski Z (1984) Automatic balancing of flexible rotors. J Sound Vib 100(4):551–567

Parkinson AG, Darlow MS, Smalley AJ (1980) A theoretical introduction to development of a unified approach to flexible rotor balancing. J Sound Vib 68:489–506

Lindley ALG, Bishop RED (1963) Some recent research on the balancing of large flexible rotors. Proc Inst Mech Eng 117:811–841

Gasch R, Nordmann R, Pfützner H (2002) Rotordynamik. Springer, Berlin

Genta G (2005) Dynamics of rotating systems. Springer, New York

Rao JS (1996) Rotor dynamics. Wiley, New York

Vance JM, Zeidan FJ, Murphy B (2010) Machinery vibration and rotordynamics. Wiley, Hoboken

Schuisky W (1972) Magnetic pull in electrical machines due to the eccentricity of the rotor. Electr Res Assoc Trans 295:391–399

Belmans R, Vandenput A, Geysen W (1987) Calculation of the flux density and the unbalanced magnetic pull in two pole induction machines. Arch Elektrotech 70:151–161

Arkkio A, Antila M, Pokki K, Simon A, Lantto E (2000) Electromagnetic force on a whirling cage rotor. IEE Proc, Electr Power Appl 147(5):353–360

Holopainen TP (2004) Electromechanical interaction in rotor dynamics of cage induction motors. VTT Technical Research Centre of Finland, PhD Thesis, Helsinki University of Technology, Finland

Werner U (2006) Rotordynamische Analyse von Asynchronmaschinen mit magnetischen Unsymmetrien. Dissertation, Technical University of Darmstadt. Shaker-Verlag, Aachen

Werner U (2009) Mathematical analysis of rotor shaft displacements in asynchronous machines; a critical speed or just a rotation of the orbit axis. Z Angew Math Mech 89(7):514–535

Tondl A (1965) Some problems of rotor dynamics. Chapman & Hall, London

Glienicke J (1967) Experimental investigation of the stiffness and damping coefficients of turbine bearings. Proc Inst Mech Eng 181:116–129

Lund J, Thomsen K (1978) A calculation method and data for the dynamics of oil lubricated journal bearings in fluid film bearings and rotor bearings system design and optimization. ASME, New York, pp 1–28

DIN 31657-1 (1996) Plain bearings—Hydrodynamic plain journal bearings under steady state conditions—Part 1: Calculation of multi-lobed and tilting pad journal bearings. Deutsches Institute für Normung

DIN 31652-1 (1983) Plain bearings; hydrodynamic plain journal bearings designed for operation under steady-state conditions; design of circular cylindrical bearings. Deutsche Institute für Normung

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Werner, U. Elastic multiple-mass model for rotordynamic analysis of flexible electrical rotors. Forsch Ingenieurwes 75, 209–229 (2011). https://doi.org/10.1007/s10010-011-0146-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-011-0146-3