Abstract

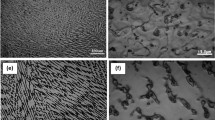

The metastable pitting characteristics of Ni-based alloy coatings in chloride ion media have been investigated, and a pitting model based on empirical electron theory (EET or Yu Ruihuang electron theory) was developed to analyze the pitting mechanism. The results indicate that higher chloride ion concentrations promote the metastable pitting behavior and increase the pitting susceptibility. However, passivation films on Ni-based alloy coatings always exhibit n-p semiconductor properties over a range of chloride ion concentrations. Metastable pitting occurs in the intergranular area of Ni-based alloy coatings because of the high cohesive energy of intergranular compounds.

Similar content being viewed by others

Data availability

All data generated and/or analyzed during this study are included in this article. The data are available from the corresponding author upon reasonable request.

References

Xia W, Zhao X, Yue L et al (2020) A review of composition evolution in Ni-based single crystal superalloys. J Mater Sci Technol 44(1):76–95

Mallikarjuna HT, Richards NL, Caley WF (2017) Isothermal oxidation comparison of three Ni-based superalloys. J Mater Eng Perform 26:2014–2023

Wang QY, Wang XZ, Luo H (2016) A study on corrosion behaviors of Ni-Cr-Mo laser coating 316 stainless steel and X70 steel in simulated solutions with H2S and CO2. Surf Coat Technol 291:250–257

Xu LY, Zhang JY, Han YD (2019) Insights into the intergranular corrosion of overlay welded joints of X65-Inconel 625 clad pipe and its relationship to damage penetration. Corros Sci 160:108169

Farias FWC, Da Cruz Payão J, Da Filho DA, Júnior S (2019) Microstructural characterization of Ni-based superalloy 625 clad welded on a 9% Ni steel pipe by plasma powder transferred arc. Surf Coat Technol 374:1024–1037

Vega JM, Ganborena L, Gonzalez-Garcia Y et al (2023) Exploring the effect of the pH on the corrosion of multilayer nickel-chromium coatings. Corros Sci 210:110819

Feng X, Wang H, Liu X et al (2021) Effect of Al content on wear and corrosion resistance of Ni-based alloy coatings by laser cladding. Surf Coat Technol 412:126976

Jie G, Yan S, Kangning W et al (2022) Effect of Fe content on microstructure and corrosion resistance of Ni-based alloy formed by laser cladding. Surf Coat Technol 446:128761

Meng Z, Shi Y, Qiao Z et al (2022) Study on microstructure and corrosion resistance of Ti-doped nickel-based alloy coatings. J Solid State Electrochem 26(8):1677–1686

Mosayebi S, Rezaei M, Mahidashti Z (2020) Comparing corrosion behavior of Ni and Ni-Mo electroplated coatings in chloride mediums. Colloids Surf A 594:124654

Song R, Zhang S, He Yi et al (2022) Silicon nitride nanoparticles reinforced the corrosion resistance of Ni-Cu composite coating in simulated seawater solution. Colloids Surf A 649:129427

Strehblow HH (2002) Mechanisms of pitting corrosion. In: Marcus P (ed) Corrosion Mechanisms in Theory and Practice, 2nd edn. Marcel Dekker AG, New York

Ter-Ovanessian B, Normand B (2016) Passive films growth on different Ni-Cr alloys from the migration of cation vacancies. J Solid State Electrochem 20:9–18

Longjun Xu, Pangang Wu, Zhu X et al (2022) Structural characteristics and chloride intrusion mechanism of passive film. Corros Sci 207:110563

Ter-Ovanessian Benoˆıt, Mary N, Normand B (2016) Passivity breakdown of Ni-Cr alloys: from anions interactions to stable pits growth. J Electrochem Soc 163(8):C410–C419

Szklarska-Smialowska Z (2002) Mechanism of pit nucleation by electrical breakdown of the passive film. Corros Sci 44:1143–1149

Natishan PM, O’Grady WE (2014) Chloride ion interactions with oxide-covered aluminum leading to pitting corrosion: a review. J Electrochem Soc 161:C421–C432

Sharifi-Asl S, Mao FX, Lua P (2015) Exploration of the effect of chloride ion concentration and temperature on pitting corrosion of carbon steel in saturated Ca (OH)2 solution. Corros Sci 98:708–715

Wang JM, Qian SS, Li YH (2019) Passivity breakdown on 436 ferritic stainless steel in solutions containing chloride. J Mater Sci Technol 35:637–643

Lin C, Yin G, Zhao Y (2015) Calculation of the cohesive energy of solids with the use of valence electron structure parameters. Comput Mater Sci 101:168–174

Lin C, Yin G, Zhao Y (2016) Analysis of the effect of alloy elements on allotropic transformation in titanium alloys with the use of cohesive energy. Comput Mater Sci 111:41–46

Lin C, Zhao YQ, Yin GL (2015) Calculation of the lattice constant of solids with the use of valence electron structure parameters. Comput Mater Sci 97:86–93

Fu BQ, Liu W, Li ZL (2010) Surface energy calculation of alkali metals with the empirical electron surface model. Mater Chem Phys 123:658–665

Gupta RK, Sukiman NL, Cavanaugh MK (2012) Metastable pitting characteristics of aluminium alloys measured using current transients during potentiostatic polarisation. Electrochim Acta 66:245–254

Wu CJ, Lin Z, Li X et al (2014) Electrochemical corrosion behavior of zinc powder sherardized carbon steel. Corros Sci Protect Technol 26(5):441–445

Li ZX, Zhang LM, Ma AL (2021) Comparative study on the cavitation erosion behavior of two different rolling surfaces on 304 stainless steel. Tribol Int 159:106994

Dean MH, Stimming U (1989) The electronic properties of disordered passive films. Corros Sci 29:199–211

Tang YB, Shen XW, Qiao YX (2021) Corrosion behavior of a selective laser melted Inconel 718 Alloy in a 3.5 wt.% NaCl Solution. J Mater Eng Perform 30:5506–5514

Wasekar NP, Hebalkar N, Jyothirmayi A (2020) Influence of pulse parameters on the mechanical properties and electrochemical corrosion behavior of electrodeposited Ni-W alloy coatings with high tungsten content. Corros Sci 165:108409

Zhang H, Zhao J, Yang C et al (2020) Corrosion resistance of Cu-bearing 316L stainless steel tuned by various passivation potentials. Wiley Analy Sci 53(6):592–602

Luo H, Gao S, Dong C, Li X (2014) Characterization of electrochemical and passive behavior of Alloy 59 in acid solution. Electrochim Acta 1350:412–419

Author information

Authors and Affiliations

Contributions

Zhongli Qiao: writing—original draft and writing—review and editing. Yanhua Shi: conceptualization and writing—review and editing. Chen Lin: methodology, writing—review and editing. Ping Liang: resources and supervision. Zixuan Meng: data curation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qiao, Z., Shi, Y., Lin, C. et al. Study on the corrosion behavior and pitting mechanism of Ni-based alloy coatings in chloride ion media. J Solid State Electrochem 27, 841–855 (2023). https://doi.org/10.1007/s10008-022-05367-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-022-05367-9