Abstract

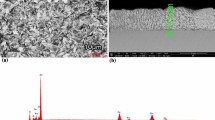

In order to improve the cathodic protection and wear resistance of cold spraying Zn-based coatings, Zn–Ni/Cu–Al2O3 composite coating was prepared by co-depositing Zn powders, nickel-coated Cu powders, and Al2O3 powders on the steel substrate using the low-pressure cold spraying method. The structure and composition of Zn–Ni/Cu–Al2O3 coatings were analyzed by scanning electron microscopy, energy dispersive spectrum analysis, and X-ray diffraction, respectively. And their wear and corrosion resistance were tested. The results show that the structure of the Zn–Ni/Cu–Al2O3 composite coating is compact and the nickel powder is evenly distributed in the coating. Compared with the Zn–Al2O3 coating and Zn–Cu–Al2O3 coating, the Zn–Ni/Cu–Al2O3 composite coating has better wear resistance in air and stronger corrosion resistance in the 3.5 wt.% NaCl solutions. The Zn–Ni/Cu–Al2O3 coating has the lowest corrosion rate and maximum impedance after the immersion and scratch tests. Due to the promoting effect of Ni, the Zn–Ni/Cu–Al2O3 coating can quickly form a dense protective layer of corrosion products, which makes the Zn–Ni/Cu–Al2O3 composite coating has better cathodic protection and defect self-repair performance.

Similar content being viewed by others

References

Stankiewicz A, Szczygieł I, Szczygieł B (2013) Self-healing coatings in anti-corrosion applications. J Mater Sci 48(23):8041–8051. https://doi.org/10.1007/s10853-013-7616-y

Nazeer AA, Madkour M (2018) Potential use of smart coatings for corrosion protection of metals and alloys: a review. J Mol Liq 253:11–22. https://doi.org/10.1016/j.molliq.2018.01.027

Stankiewicz A, Barker MB (2016) Development of self-healing coatings for corrosion protection on metallic structures. Smart Mater Struct 25(8). https://doi.org/10.1088/0964-1726/25/8/084013

Montemor MF (2014) Functional and smart coatings for corrosion protection: a review of recent advances. Surf Coat Technol 258:17–37. https://doi.org/10.1016/j.surfcoat.2014.06.031

Lazorenko G, Kasprzhitskii A, Nazdracheva T (2021) Anti-corrosion coatings for protection of steel railway structures exposed to atmospheric environments: a review. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2021.123115

Malarvannan RRR, Moorthy TV, Sathish S, Hariharan P (2015) Investigation on the corrosion behavior of physical vapor deposition coated high speed steel. Adv Mech Eng 7(8). https://doi.org/10.1177/1687814015599524

Yoganandan G, Balaraju JN (2014) Synergistic effect of V and Mn oxyanions for the corrosion protection of anodized aerospace aluminum alloy. Surf Coat Technol 252:35–47. https://doi.org/10.1016/j.surfcoat.2014.04.062

Paz Martínez-Viademonte M, Abrahami ST, Hack T, Burchardt M, Terryn H (2020) A review on anodizing of aerospace aluminum alloys for corrosion protection. Coatings 10(11). https://doi.org/10.3390/coatings10111106

Liu C, Wei D, Huang X, Mai Y, Zhang L, Jie X (2019) Electrodeposition of Co–Ni–P/graphene oxide composite coating with enhanced wear and corrosion resistance. J Mater Res 34(10):1726–1733. https://doi.org/10.1557/jmr.2019.15

Zhang Y, Descartes S, Vo P, Chromik RR (2015) Cold-sprayed Cu-MoS2 and its fretting wear behavior. J Therm Spray Technol 25(3):473–482. https://doi.org/10.1007/s11666-015-0372-6

Raoelison RN, Verdy C, Liao H (2017) Cold gas dynamic spray additive manufacturing today: deposit possibilities, technological solutions and viable applications. Mater Des 133:266–287. https://doi.org/10.1016/j.matdes.2017.07.067

Spencer K, Fabijanic DM, Zhang MX (2009) The use of Al–Al2O3 cold spray coatings to improve the surface properties of magnesium alloys. Surf Coat Technol 204(3):336–344. https://doi.org/10.1016/j.surfcoat.2009.07.032

Wang Q, Spencer K, Birbilis N, Zhang M-X (2010) The influence of ceramic particles on bond strength of cold spray composite coatings on AZ91 alloy substrate. Surf Coat Technol 205(1):50–56. https://doi.org/10.1016/j.surfcoat.2010.06.008

Kang H-K, Kang SB (2003) Tungsten/copper composite deposits produced by a cold spray. Scr Mater 49(12):1169–1174. https://doi.org/10.1016/j.scriptamat.2003.08.023

Chen W, Yu Y, Cheng J, Wang S, Zhu S, Liu W et al (2018) Microstructure, mechanical properties and dry sliding wear behavior of Cu-Al2O3-graphite solid-lubricating coatings deposited by low-pressure cold spraying. J Therm Spray Technol 27(8):1652–1663. https://doi.org/10.1007/s11666-018-0773-4

Wei Y-K, Li Y-J, Zhang Y, Luo X-T, Li C-J (2018) Corrosion resistant nickel coating with strong adhesion on AZ31B magnesium alloy prepared by an in-situ shot-peening-assisted cold spray. Corros Sci 138:105–115. https://doi.org/10.1016/j.corsci.2018.04.018

Xie C, Li H, Zhou X, Sun C (2019) Corrosion behavior of cold sprayed pure zinc coating on magnesium. Surf Coat Technol 374:797–806. https://doi.org/10.1016/j.surfcoat.2019.06.068

Zhang L, Yang S, Lv X, Jie X (2019) Wear and corrosion resistance of cold-sprayed Cu-based composite coatings on magnesium substrate. J Therm Spray Technol 28(6):1212–1224. https://doi.org/10.1007/s11666-019-00887-9

Wang Y (2022) Enhanced corrosion and wear resistance of AZ91 magnesium alloy by fabrication of galvanized Zn-Al-Mg coating in chloride solution. Int J Electrochem Sci. https://doi.org/10.20964/2022.05.65

Lu X, Wang S, Xiong T, Wen D, Wang G, Du H (2019) Anticorrosion properties of Zn–Al composite coating prepared by cold spraying. Coatings 9(3). https://doi.org/10.3390/coatings9030210

Lee M-H, Kim Y-W, Lim K-M, Lee S-H, Moon K-M (2013) Electrochemical evaluation of zinc and magnesium alloy coatings deposited on electrogalvanized steel by PVD. Transactions of Nonferrous Metals Society of China 23(3):876–880. https://doi.org/10.1016/s1003-6326(13)62542-x

Bai Y, Wang Z, Li X, Huang G, Li C, Li Y (2018) Microstructure and mechanical properties of Zn-Ni-Al2O3 composite coatings. Materials (Basel, Switzerland) 11(5). https://doi.org/10.3390/ma11050853

Arai S, Endo M, Hashizume S, Shimojima Y (2004) Nickel-coated carbon nanofibers prepared by electroless deposition. Electrochem Commun 6(10):1029–1031. https://doi.org/10.1016/j.elecom.2004.08.001

Li Y-J, Luo X-T, Rashid H, Li C-J (2018) A new approach to prepare fully dense Cu with high conductivities and anti-corrosion performance by cold spray. J Alloys Compd 740:406–413. https://doi.org/10.1016/j.jallcom.2017.11.053

Liu C, Wei D, Xu R, Mai Y, Zhang L, Jie X (2020) Electroplated Co-Ni/WS2 composite coating with excellent tribological and anticorrosion performance. Tribol Trans 63(5):857–866. https://doi.org/10.1080/10402004.2020.1759742

Wu H, Zhang L, Liu C, Mai Y, Zhang Y, Jie X (2020) Deposition of Zn-G/Al composite coating with excellent cathodic protection on low-carbon steel by low-pressure cold spraying. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2019.153483

Bai Y, Wang ZH, Li XB, Huang GS, Li CX, Li Y (2017) Corrosion behavior of low pressure cold sprayed Zn-Ni composite coatings. J Alloys Compd 719:194–202. https://doi.org/10.1016/j.jallcom.2017.05.134

Ding R, Chen S, Zhou N, Zheng Y, Li BJ, Gui TJ et al (2019) The diffusion-dynamical and electrochemical effect mechanism of oriented magnetic graphene on zinc-rich coatings and the electrodynamics and quantum mechanics mechanism of electron conduction in graphene zinc-rich coatings. J Alloys Compd 784:756–768. https://doi.org/10.1016/j.jallcom.2019.01.070

Shen G, Zhang L, Wu W, Wu H, Gu Z, Liu S et al (2022) Design and fabrication of enhanced corrosion-resistant LDH-Zn-G/Ni dual-layer structural coatings on magnesium alloys. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2022.165475

Conde A, De Damborenea JJ (2002) Electrochemical impedance spectroscopy for studying the degradation of enamel coatings. Corros Sci 44:1555–1567. https://doi.org/10.20964/2022.05.65

Xue Q, Sun Cy YuJY, Huang L, Wei J, Zhang J (2017) Microstructure evolution of a Zn-Al coating co-deposited on low-carbon steel by pack cementation. J Alloys Compd 699:1012–1021. https://doi.org/10.1016/j.jallcom.2016.12.291

Funding

This work was supported by the National Natural Science Foundation of China (No. 52105176 and No. 51709049), the National Key R&D Program of China (2021YFB3400601), and the Program for Guangdong Introducing Innovative and Entrepreneurial Teams (2019BT02Z393).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Y., Tan, G., Tang, J. et al. Enhanced corrosion and wear resistance of Zn–Ni/Cu–Al2O3 composite coating prepared by cold spray. J Solid State Electrochem 27, 439–453 (2023). https://doi.org/10.1007/s10008-022-05335-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-022-05335-3