Abstract

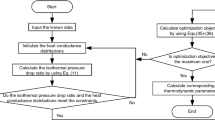

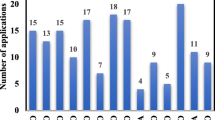

As a novel renewable energy cell type, flat tubular solid oxide fuel cell (FT-SOFC) has the advantages of easy sealing, low resistance, and better stability. Optimization for fuel cell output performance was traditionally implemented through the combination and comparison of a set of experiments or simulations. Optimization algorithms are rarely used in the single cell field. This work contributes to the fuel cell development on performance optimization by combining the numerical simulation with the Nelder-Mead simplex optimization algorithm, where multi-variables are optimized simultaneously. The numerical model is developed based on the constructed three-dimensional FT-SOFC model which fully couples the chemical and physical processes. The dependence of cell performance on a variety of operating and structural characteristics is studied, and five strong correlation parameters are selected as decision variables. Through the simulation-based optimization framework, an optimal combination of these parameters for the maximum power density is obtained. Compared with the original FT-SOFC, the average current density and average power density of the optimized cell is increased by 10.4% and 9.0%, respectively. The optimal solution tends to adopt a higher reactant concentration, and a superior proportion of inlet/outlet width is acquired. In particular, the optimized wide inlet and narrow outlet channel contributes to even current density distribution. The results highlight that the simulation-based optimization has great potential in fuel cell improvements as well as the broad renewable energy application.

Similar content being viewed by others

Abbreviations

- C i :

-

molar concentration, mol/m3

- R :

-

gas constant, kJ/(kmol K)

- C p :

-

heat capacity, J/(kg K)

- T :

-

temperature, K

- d k :

-

diffusional driving force, m−1

- V cell :

-

cell voltage, V

- D ik :

-

multicomponent Fick diffusivities, m2/s

- x :

-

mole fraction

- \({D}_{i}^{T}\) :

-

thermal diffusion coefficient, kg/(m s)

- α :

-

charge transfer coefficient

- F :

-

Faraday’s constant, C/mol

- ɛ :

-

porosity

- ΔG T.P :

-

Gibbs free energy, kJ/mol

- η :

-

overpotential, V

- i :

-

current density, A/m2

- κ :

-

permeability

- j i :

-

relative mass flux, kg/(m2·s)

- λ :

-

thermal conductivity, W/(m K)

- M i :

-

molar mass, kg/mol

- μ :

-

viscosity, Pa s

- P i :

-

partial pressure, Pa

- ρ :

-

density, kg/m3

- Q :

-

heat source, W/m3

- σ :

-

electrical conductivity, S/m

- u :

-

velocity, m/s

- Φ :

-

potential, V

- V pol :

-

polarization, V

- ɷ i :

-

mass fraction

References

Ramadhani F, Hussain MA, Mokhlis H, Hajimolana S (2017) Optimization strategies for solid oxide fuel cell (SOFC) application: A literature survey. Renew Sustain Energy Rev 76:460–484. https://doi.org/10.1016/j.rser.2017.03.052

Huang Y, Lin Q, Liu H et al (2017) Evaluation of the waste heat and residual fuel from the solid oxide fuel cell and system power optimization. Int J Heat Mass Transf 115:1166–1173. https://doi.org/10.1016/j.ijheatmasstransfer.2017.07.115

Ghorbani B, Vijayaraghavan K (2018) 3D and simplified pseudo-2D modeling of single cell of a high temperature solid oxide fuel cell to be used for online control strategies. Int J Hydrog Energy 43:9733–9748. https://doi.org/10.1016/j.ijhydene.2018.03.211

Park K, Yu S, Bae J et al (2010) Fast performance degradation of SOFC caused by cathode delamination in long-term testing. Int J Hydrog Energy 35:8670–8677. https://doi.org/10.1016/j.ijhydene.2010.05.005

Choudhury A, Chandra H, Arora A (2013) Application of solid oxide fuel cell technology for power generation—a review. Renew Sustain Energy Rev 20:430–442. https://doi.org/10.1016/j.rser.2012.11.031

Tikiz I, Taymaz I (2016) An experimental investigation of solid oxide fuel cell performance at variable operating conditions. Therm Sci 20:1421–1433. https://doi.org/10.2298/TSCI130617019T

Singhal S (2000) Advances in solid oxide fuel cell technology. Solid State Ion 135:305–313. https://doi.org/10.1016/S0167-2738(00)00452-5

Ho TX, Kosinski P, Hoffmann AC, Vik A (2010) Effects of heat sources on the performance of a planar solid oxide fuel cell. Int J Hydrog Energy 35:4276–4284. https://doi.org/10.1016/j.ijhydene.2010.02.016

Pianko-Oprych P, Zinko T, Jaworski Z (2016) A Numerical investigation of the thermal stresses of a planar solid oxide fuel cell. Materials 9:814. https://doi.org/10.3390/ma9100814

Fischer K, Seume JR (2009) Impact of the temperature profile on thermal stress in a tubular solid oxide fuel cell. J Fuel Cell Sci Technol 6:011017. https://doi.org/10.1115/1.2971132

Gao J-T, Li J-H, Wang Y-P et al (2020) Self-sealingmetal-supported sofc fabricated by plasma spraying and its performance underunbalanced gas pressure. J Therm Spray Technol 29:2001–2011. https://doi.org/10.1007/s11666-020-01096-5

Liu R, Zhao C, Li J et al (2010) Testing of a cathode fabricated by painting with a brush pen for anode-supported tubular solid oxide fuel cells. J Power Sources 195:541–545. https://doi.org/10.1016/j.jpowsour.2009.06.099

Ilbas M, Kumuk B, Alemu MA, Arslan B (2020) Numerical investigation of a direct ammonia tubular solid oxide fuel cell in comparison with hydrogen. Int J Hydrog Energy 45:35108–35117. https://doi.org/10.1016/j.ijhydene.2020.04.060

Park J, Bae J, Kim J-Y (2012) A numerical study onanode thickness and channel diameter of anode-supported flat-tube solid oxidefuel cells. Renew Energy 42:180–185. https://doi.org/10.1016/j.renene.2011.08.022

Han Z, Wang Y, Yang Z, Han M (2016) Electrochemical properties of tubular sofc based on a porous ceramic support fabricated byphase-inversion method. J Mater Sci Technol 32:681–686. https://doi.org/10.1016/j.jmst.2016.03.002

Huang K, Singhal SC (2013) Cathode-supported tubularsolid oxide fuel cell technology: A critical review. J Power Sources 237:84–97. https://doi.org/10.1016/j.jpowsour.2013.03.001

Gong S, Zeng H, Lin J et al (2018) A robust flat-chip solid oxide fuel cell coupled with catalytic partial oxidation of methane. J Power Sources 402:124–132. https://doi.org/10.1016/j.jpowsour.2018.09.017

Lu Y, Schaefer L (2006) Numerical study of a flat-tubehigh power density solid oxide fuel cell. J Power Sources 153:68–75. https://doi.org/10.1016/j.jpowsour.2005.03.189

Lim T-H, Park J-L, Lee S-B et al (2010) Fabricationand operation of a 1 kW class anode-supported flat tubular SOFC stack. Int JHydrog Energy 35:9687–9692. https://doi.org/10.1016/j.ijhydene.2010.06.052

Ghorbani B, Vijayaraghavan K (2019) A review study on software-based modeling of hydrogen-fueled solid oxide fuel cells. Int J Hydrog Energy 44:13700–13727. https://doi.org/10.1016/j.ijhydene.2019.03.217

Khodabandeh E, Akbari OA, Akbari S et al (2021) The effects of oil/MWCNT nanofluids and geometries on the solid oxide fuel cell cooling systems: a CFD study. J Therm Anal Calorim 144:245–256. https://doi.org/10.1007/s10973-020-09422-3

Mohd Nazrul Aman NA, Muchtar A, Somalu MR et al (2018) A short review on the modeling of solid-oxide fuel cells by using computational fluid dynamics: assumptions and boundary conditions. Int J Integr Eng 10:87–92. https://doi.org/10.30880/ijie.2018.10.05.014

Lu X, Bertei A, Heenan TMM et al (2019) Multi-length scale microstructural design of micro-tubular solid oxide fuel cells for optimised power density and mechanical robustness. J Power Sources 434:226744. https://doi.org/10.1016/j.jpowsour.2019.226744

Cui D, Ji Y, Chang C et al (2020) Influence of structure size on voltage uniformity of flat tubular segmented-in-series solid oxide fuel cell. J Power Sources 460:228092. https://doi.org/10.1016/j.jpowsour.2020.228092

Park J, Bae J, Kim J-Y (2011) The current density and temperature distributions of anode-supported flat-tube solid oxide fuel cells affected by various channel designs. Int J Hydrog Energy 36:9936–9944. https://doi.org/10.1016/j.ijhydene.2011.04.168

Murray PM, Bellany F, Benhamou L et al (2016) The application of design of experiments (DoE) reaction optimisation and solvent selection in the development of new synthetic chemistry. Org Biomol Chem 14:2373–2384. https://doi.org/10.1039/C5OB01892G

Fath V, Kockmann N, Otto J, Röder T (2020) Self-optimising processes and real-time-optimisation of organic syntheses in a microreactor system using Nelder-Mead and design of experiments. React Chem Eng 5:1281–1299. https://doi.org/10.1039/D0RE00081G

Abdullah T, Liu L (2016) Simulation-based microstructural optimization of solid oxide fuel cell for low temperature operation. Int J Hydrog Energy 41:13632–13643. https://doi.org/10.1016/j.ijhydene.2016.05.177

Feng H, Chen L, Xie Z, Sun F (2015) Constructal optimization for a single tubular solid oxide fuel cell. J Power Sources 286:406–413. https://doi.org/10.1016/j.jpowsour.2015.03.162

Bunin GA, François G, Bonvin D (2010) Two-layered real-time optimization of a solid oxide fuel cell stack. IFAC Proc 43:847–852. https://doi.org/10.3182/20100705-3-BE-2011.00140

Zhao Y, Shah N, Brandon N (2011) Comparison between two optimization strategies for solid oxide fuel cell–gas turbine hybrid cycles. Int J Hydrog Energy 36:10235–10246. https://doi.org/10.1016/j.ijhydene.2010.11.015

Zhang L, Li X, Jiang J et al (2015) Dynamic modeling and analysis of a 5-kW solid oxide fuel cell system from the perspectives of cooperative control of thermal safety and high efficiency. Int J Hydrog Energy 40:456–476. https://doi.org/10.1016/j.ijhydene.2014.10.149

Cao H, Li X, Deng Z et al (2013) Thermal management oriented steady state analysis and optimization of a kW scale solid oxide fuelcell stand-alone system for maximum system efficiency. Int J Hydrog Energy 38:12404–12417. https://doi.org/10.1016/j.ijhydene.2013.07.052

Secanell M, Wishart J, Dobson P (2011) Computational design and optimization of fuel cells and fuel cell systems: A review. J Power Sources 196:3690–3704. https://doi.org/10.1016/j.jpowsour.2010.12.011

Nelder JA, Mead R (1965) A simplex method for function minimization. Comput J 7:308–313. https://doi.org/10.1093/comjnl/7.4.308

Conn AR, Scheinberg K, Vicente LN (2009) Introduction to derivative-free optimization. Society for Industrial and Applied Mathematics, Philadelphia

Lee Y, Resiga A, Yi S, Wern C (2020) The optimization of machining parameters for milling operations by using the Nelder-Mead simplex method. J Manuf Mater Process 4:66. https://doi.org/10.3390/jmmp4030066

Lin B, Shi Y, Cai N (2017) Numerical simulation of cell-to-cell performance variation within a syngas-fuelled planar solid oxide fuel cell stack. Appl Therm Eng 114:653–662. https://doi.org/10.1016/j.applthermaleng.2016.12.014

Yang P, Wang Y, Jin Z (2021) Numerical simulation study on operation characteristics of PEMFC in low temperature environment. J Renew Sustain Energy 13:014301. https://doi.org/10.1063/5.0021429

Kuo J-K, Wang J-K (2012) Characteristic simulation with various anode support thicknesses of membrane electrode assembly in SOFC. J Solid State Electrochem 16:329–340. https://doi.org/10.1007/s10008-011-1328-5

Acknowledgements

The authors thank Zhejiang Zhentai Energy Technology Co. Ltd for providing the FT-SOFC. The authors also appreciate the editor and reviewers for their constructive comments.

Funding

We received support from the Key Research and Development Program of Zhejiang (Grant No. 2021C01100).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liao, J., Jie, H., Zhang, C. et al. Numerical simulation and optimization of operating and structural parameters for solid oxide fuel cell. J Solid State Electrochem 25, 2321–2332 (2021). https://doi.org/10.1007/s10008-021-05007-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-021-05007-8