Abstract

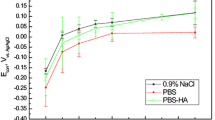

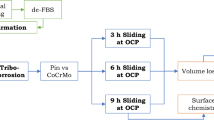

The low carbon Co28Cr6Mo alloy used for artificial joints like hip and knee prostheses is subjected to a surface treatment called SMAT (surface mechanical attrition treatment). The purpose of this treatment is to modify the surface mechanical properties of the treated alloy. Since the SMAT impacts the surface of materials, its influence on the corrosion behavior of the CoCrMo alloy has to be assessed in a physiological solution as Ringer’s solution. Furthermore, a specific biomedical polishing is coupled with the SMAT in order to finalize the production of a hip prosthesis ready for use. The corresponding corrosion behavior is also studied. The corrosion behavior of CoCrMo alloy samples is investigated using electrochemical techniques (potentiodynamic polarization measurements and electrochemical impedance spectroscopy (EIS)) in physiological liquid and simulated by an equivalent circuit. The polarization results show the reduction of the corrosion current density and the increase of the corrosion potential after the SMAT. The EIS analyses also show the benefit of the SMAT on the corrosion resistance of the CoCrMo alloy. The surface morphology modification and the phase’s transformation induced by the SMAT are evaluated by scanning electron microscopy (SEM) and X-ray diffraction (XRD).

Similar content being viewed by others

References

KaivosojaE, TiainenVM, TakakuboY, RajchelB, SobieckiJ, KonttinenYT, TakagiM (2013) In: Affatato S (ed) Wear of orthopaedic implants and artificial joints, A volume in Woodhead Publishing Series in Biomaterials, Cambridge

Martin CT, Callaghan JJ, Gao Y, Pugely AJ, Liu SS, Warth LC, Goetz DD (2016) What can we learn from 20-year followup studies of hip replacement? Clin Orthop Relat Res 474(2):402–407. https://doi.org/10.1007/s11999-015-4260-7

Kamath AF, Sheth NP, Hosalkar HH, Babatunde OM, Lee GC, Nelson CL (2012) Modern total hip arthroplasty in patients younger than 21 years. J Arthroplast 27(3):402–408. https://doi.org/10.1016/j.arth.2011.04.042

Pezzotti G, Yamamoto K (2014) Artificial hip joints: the biomaterials challenge. J Mech Behav Biomed Mater 31:3–20. https://doi.org/10.1016/j.jmbbm.2013.06.001

Wang XH, Li JS, Hu R, Kou HC (2015) Mechanical properties and pore structure deformation behaviour of biomedical porous titanium. Trans Nonferrous Met Soc China 25(5):1543–1550. https://doi.org/10.1016/S1003-6326(15)63756-6

Niinomi M (2008) Metallic biomaterials. J Artif Organs 11(3):105–110. https://doi.org/10.1007/s10047-008-0422-7

Jaimes RFVV, Afonso MLCA, Rogero SO, Agostinho SML, Barbosa CA (2010) New material for orthopedic implants: electrochemical study of nickel free P558 stainless steel in minimum essential medium. Mater Lett 64(13):1476–1479. https://doi.org/10.1016/j.matlet.2010.03.066

Geetha M, Singh AK, Asokamani R, Gogia AK (2009) Ti based biomaterials, the ultimate choice for orthopaedic implants—a review. Prog Mater Sci 54(3):397–425. https://doi.org/10.1016/j.pmatsci.2008.06.004

Simon JP, Fabry G (1991) An overview of implants materials. Acta Orthop Belg 57(1):1–5

Jin L, Cui W, Song X, Liu G, Zhou L (2014) Effects of surface nanocrystallization on corrosion resistance of β-type titanium alloy. Trans Nonferrous Met Soc China 24(8):2529–2535. https://doi.org/10.1016/S1003-6326(14)63379-3

Liu G, Lu J, Lu K (2000) Surface nanocrystallization of 316L stainless steel induced by ultrasonic shot peening. Mater Sci Eng A 286(1):91–95. https://doi.org/10.1016/S0921-5093(00)00686-9

Liu G, Wang SC, Lou XF, Lu J, Lu K (2001) Low carbon steel with nanostructured surface layer induced by high-energy shot peening. Scripta Mater 44(8-9):1791–1795. https://doi.org/10.1016/S1359-6462(01)00738-2

Zhang K, Zhang X, Deng X, Li X, Ma M (2013) Relationship between extrusion, Y and corrosion behavior of Mg-Y alloy in NaCl solution. J Magnesium Alloys 1(2):134–138. https://doi.org/10.1016/j.jma.2013.07.002

Yang S, Dillon OW, Puleo D, Jawahir IS (2013) Effect of cryogenic burnishing on surface integrity modifications of Co-Cr-Mo biomedical alloy. J Biomed Mater Res B Appl Biomater 101B(1):139–152. https://doi.org/10.1002/jbm.b.32827

Ralston KD, Birbilis N, Davies CHJ (2010) Revealing the relationship between grain size and corrosion rate of metals. Scripta Mater 63(12):1201–1204. https://doi.org/10.1016/j.scriptamat.2010.08.035

Balusamy T, Sankara Narayanan TSN, Ravichandran K, Park IS, Lee MH (2013) Influence of surface mechanical attrition treatment (SMAT) on the corrosion behaviour of AISI 304 stainless steel. Corros Sci 74:332–344. https://doi.org/10.1016/j.corsci.2013.04.056

Hao YW, Deng B, Zhong C, Jiang YM, Li J (2009) Effect of surface mechanical attrition treatment on corrosion behavior of 316 stainless steel. J Iron Steel Res Int 16(2):68–72. https://doi.org/10.1016/S1006-706X(09)60030-3

Balusamy T, Kumar S, Sankara Narayanan TSN (2010) Effect of surface nanocrystallization on the corrosion behaviour of AISI 409 stainless steel. Corros Sci 52(11):3826–3834. https://doi.org/10.1016/j.corsci.2010.07.004

Jelliti S, Richard C, Retraint D, Roland T, Chemkhi M, Demangel C (2013) Effect of surface nanocrystallization on the corrosion behavior of Ti-6Al-4V titanium alloy. Surf Coat Technol 224:82–87. https://doi.org/10.1016/j.surfcoat.2013.02.052

Petrov YN, Prokopenko GI, Mordyuk BN, Vasylyev MA, Voloshko SM, Skorodzievski VS, Filatova VS (2016) Influence of microstructural modifications induced by ultrasonic impact treatment on hardening and corrosion behavior of wrought Co-Cr-Mo biomedical alloy. Mater Sci Eng C 58:1024–1035. https://doi.org/10.1016/j.msec.2015.09.004

Demangel C, Poznanski A, Steenhout V, Levesque A, Benhayoune H, Retraint D (2014) Benefit of a surface nanocrystallization treatment on Co28Cr6Mo abrasive wear properties. Adv Mater Res 966–967:435–441. https://doi.org/10.4028/www.scientific.net/AMR.966-967.435

Zhang LC, Kiat ECS, Pramanik A (2009) A briefing on the manufacture of hip joint prostheses. Adv Mater Res 76-78:212–216. https://doi.org/10.4028/www.scientific.net/AMR.76-78.212

Lu K, Lu J (2004) Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment. Mat Sci Eng A 375–377:38–45

Yamanaka K, Mori M, Kurosu S, Matsumoto H, Chiba A (2009) Ultrafine grain refinement of biomedical Co-29Cr-6Mo alloy during conventional hot-compression deformation. Metall Mater Trans A 40(8):1980–1994. https://doi.org/10.1007/s11661-009-9879-0

Drevet R, Aaboubi O, Benhayoune H (2012) In vitro corrosion behavior of electrodeposited calcium phosphate coatings on Ti6Al4V substrates. J Solid State Electrochem 16(9):3069–3077. https://doi.org/10.1007/s10008-012-1742-3

Wu X, Tao N, Hong Y, Liu G, Xu B, Lu J, Lu K (2005) Strain-induced grain refinement of cobalt during surface mechanical attrition treatment. Acta Mater 53(3):681–691. https://doi.org/10.1016/j.actamat.2004.10.021

McCafferty E (2005) Validation of corrosion rates measured by the Tafel extrapolation method. Corros Sci 47(12):3202–3215. https://doi.org/10.1016/j.corsci.2005.05.046

Fu T, Zhan Z, Zhang L, Yang Y, Liu Z, Liu J, Li L, Yu X (2015) Effect of surface mechanical attrition treatment on corrosion resistance of commercial pure titanium. Surf Coat Technol 280:129–135. https://doi.org/10.1016/j.surfcoat.2015.08.041

Luo H, Dong CF, Xiao K, Li XG (2011) Characterization of passive film on 2205 duplex stainless steel in sodium thiosulphate solution. Appl Surf Sci 258(1):631–639. https://doi.org/10.1016/j.apsusc.2011.06.077

Li H, Jiang Z, Feng H, Wang Q, Zhang W, Fan G, Li G, Wang L (2015) Electrochemical corrosion characteristics of super duplex stainless steel S32750 in LT-MED environment. Int J Electrochem Sci 10:1616–1631

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tchana Nkonta, D.V., Simescu-Lazar, F., Drevet, R. et al. Influence of the surface mechanical attrition treatment (SMAT) on the corrosion behavior of Co28Cr6Mo alloy in Ringer’s solution. J Solid State Electrochem 22, 1091–1098 (2018). https://doi.org/10.1007/s10008-017-3851-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-017-3851-5