Abstract

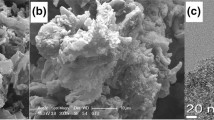

At lower operation temperature of intermediate temperature solid oxide fuel cells (IT-SOFC), polarization resistance was recognized as a limiting step because polarization at cathode is dependent on the rate of oxygen reduction reaction. The enhancement of cathode microstructure is one of the effective ways to improve the reaction rate. Pore former addition method is proven to be able to tailor the microstructure of cathode. The addition of polyether ether ketone (PEEK) as pore former was evaluated and compared with common pore formers (corn starch and graphite) for the microstructure cathode layer. Brush painting technique was used to deposit cathode layer on anode/electrolyte dual layer support hollow fiber. X-ray diffraction (XRD) analysis had proven that the resulting layer was free from impurities after the sintering treatment. Corn starch was able to induced cathode layer with coarse and large interconnected pores for efficient gas diffusion, as was proven by the SEM analysis. Additionally, SEM analysis also showed the formation of fine micropores throughout the layer when graphite was used as the pore former that can provide the increase in triple phase boundary region (TPB) in the layer. PEEK was able to generate both high porosity for oxygen diffusion to the reactive sites and increased number of TPB by the formation of fine microstructure pores in the cathode layer.

Similar content being viewed by others

References

Singhal SC, Kendall K (2003) Introduction to SOFCs. In: High temp. solid oxide fuel cells. Elsevier, Oxford, UK, pp 1–22

Minh NQ, Takahashi T (1995) Introduction. In: Science and technology of ceramic fuel cells. Elsevier, Amsterdam, pp 1–14

Baqué L, Caneiro A, Moreno MS, Serquis A (2008) High performance nanostructured IT-SOFC cathodes prepared by novel chemical method. Electrochem commun 10:1905–1908

Nie L, Liu J, Zhang Y, Liu M (2011) Effects of pore formers on microstructure and performance of cathode membranes for solid oxide fuel cells. J Power Sources 196:9975–9979

Peña-Martínez J, Marrero-López D, Sánchez-Bautista C, Dos Santos-García AJ, Ruiz-Morales JC, Canales-Vázquez J, Núñez P (2010) Effect of a CGO buffer layer on the performance of (La0.6Sr0.4)0.995Co0.2Fe0.8O3-d cathode in YSZ-based SOFC. Boletín de la Sociedad Española de Cerámica y Vidrio 49:15–22

Teraoka Y, Zhang HM, Okamoto K, Yamazoe N (1988) Mixed ionic-electronic conductivity of La1−xSrxCo1−yFeyO3−δ perovskite-type oxides. Mater Res Bull 23:51–58

Esquirol A, Brandon NP, Kilner JA, Mogensen M (2004) Electrochemical characterization of La0.6Sr0.4Co0.2Fe0.8O3 cathodes for intermediate-temperature SOFCs. J Electrochem Soc 151:A1847

Tu HY, Phillipps MB, Takeda Y, Ichikawa T, Imanishi N, Sammes NM, Yamamoto O (1999) Gd1-xAxMn1-yCoyO3-δ (A=Sr, Ca) as a cathode for solid-oxide fuel cells. J Electrochem Soc 146:2085

Reshetenko TV, Kim H-T, Kweon H-J (2007) Cathode structure optimization for air-breathing DMFC by application of pore-forming agents. J Power Sources 171:433–440

Prestat M, Morandi A, Heel A, Holzer L, Holtappels P, Graule TJ (2010) Effect of graphite pore former on oxygen electrodes prepared with La0.6Sr0.4CoO3-δ nanoparticles. Electrochem commun 12:292–295

Kenney B, Karan K (2007) Engineering of microstructure and design of a planar porous composite SOFC cathode: a numerical analysis. Solid State Ionics 178:297–306

Barbucci A, Viviani M, Panizza M, Delucchi M, Cerisola G (2005) Analysis of the oxygen reduction process on SOFC composite electrodes. J Appl Electrochem 35:399–403

Cho Y-H, Jung N, Kang YS, Chung DY, Lim JW, Choe H, Cho Y-H, Sung Y-E (2012) Improved mass transfer using a pore former in cathode catalyst layer in the direct methanol fuel cell. Int J Hydrogen Energy 37:11969–11974

Mingyi L, Bo Y, Jingming X, Jing C (2010) Influence of pore formers on physical properties and microstructures of supporting cathodes of solid oxide electrolysis cells. Int J Hydrogen Energy 35:2670–2674

Hu J, Lü Z, Chen K, Huang X, Ai N, Du X, Fu C, Wang J, Su W (2008) Effect of composite pore-former on the fabrication and performance of anode-supported membranes for SOFCs. J Membrane Science 318:445–451

Poon M, Kesler O (2012) The influence of pore formers on the microstructure of plasma-sprayed NiO-YSZ anodes. J Power Sources 210:204–217

Haslam JJ, Pham A-Q, Chung BW, DiCarlo JF, Glass RS (2005) Effects of the use of pore formers on performance of an anode supported solid oxide fuel cell. J Am Ceram Soc 88:513–518

Sanson A, Pinasco P, Roncari E (2008) Influence of pore formers on slurry composition and microstructure of tape cast supporting anodes for SOFCs. J Eur Ceram Soc 28:1221–1226

Nie L, Liu Z, Liu M, Yang L, Zhang Y, Liu M (2010) Enhanced performance of La0.6Sr0.4Co0.2Fe0.8O3-δ (LSCF) cathodes with graded microstructure fabricated by tape casting. J Electrochem Sci Technol 1:50–56

Horri BA, Selomulya C, Wang H (2012) Characteristics of Ni/YSZ ceramic anode prepared using carbon microspheres as a pore former. Int J Hydrogen Energy 37:15311–15319

Sarikaya A, Dogan F (2013) Effect of various pore formers on the microstructural development of tape-cast porous ceramics. Ceram Int 39:403–413

Medyanik SN, Karpov EG, Liu WK (2006) Domain reduction method for atomistic simulations. J Comput Phys 218:836–859

Othman MHD, Droushiotis N, Wu Z, Kelsall G, Li K (2011) Novel fabrication technique of hollow fibre support for micro-tubular solid oxide fuel cells. J Power Sources 196:5035–5044

Othman MHD, Droushiotis N, Wu Z, Kelsall G, Li K (2011) High-performance, anode-supported, microtubular SOFC prepared from single-step-fabricated, dual-layer hollow fibers. Adv Mater 23:2480–2483

Droushiotis N, Doraswami U, Ivey D, Othman MHD, Li K, Kelsall G (2010) Fabrication by co-extrusion and electrochemical characterization of micro-tubular hollow fibre solid oxide fuel cells. Electrochem commun 12:792–795

Othman MHD, Wu Z, Droushiotis N, Doraswami U, Kelsall G, Li K (2010) Single-step fabrication and characterisations of electrolyte/anode dual-layer hollow fibres for micro-tubular solid oxide fuel cells. J Memb Sci 351:196–204

Droushiotis N, Torabi A, Othman MHD, Etsell TH, Kelsall GH (2012) Effects of lanthanum strontium cobalt ferrite (LSCF) cathode properties on hollow fibre micro-tubular SOFC performances. J Appl Electrochem 42:517–526

Liu S, Li K, Hughes R (2003) Preparation of porous aluminium oxide (Al2O3) hollow fibre membranes by a combined phase-inversion and sintering method. Ceram Int 29:875–881

Guan Y, Pan X, Liu G, Liang Z, Chen S, Zhang X, Xiong Y, Tian Y, Xia C (2013) Analysis of impact of sintering temperature on microstructure of LSCF-SDC composite cathodes using nano-CT. In: Lai B (ed) Proc. SPIE. pp 885112–885116

Lee SJ, Lee JM, Kim YG, Yoon SD, Yun JW (2014) Thermal cycle development of PMMA pore former removal for honeycomb-type SOFC supports. Ceram Int 40:4879–4887

Yuan C, Liu Y, Zhou Y, Zhan Z, Wang S (2013) Fabrication and characterization of a cathode-support solid oxide fuel cell by tape casting and lamination. Int J Hydrogen Energy 38:16584–16589

Kingsbury BFK, Li K (2009) A morphological study of ceramic hollow fibre membranes. J Memb Sci 328:134–140

Tomkiewicz AC, Meloni M, McIntosh S (2014) On the link between bulk structure and surface activity of double perovskite based SOFC cathodes. Solid State Ionics 260:55–59

Küngas R, Bidrawn F, Mahmoud E, Vohs JM, Gorte RJ (2012) Evidence of surface-reaction rate limitations in SOFC composite cathodes. Solid State Ionics 225:146–150

Wu X, Weng D, Xu L, Li H (2001) Structure and performance of γ-alumina washcoat deposited by plasma spraying. Surf Coatings Technol 145:226–232

Sun H, Ma W, Yu J, Chen X, Lin H (2010) Preparation and characterization of La0.8Sr0.04Ca0.16Co0.6Fe0.4O3-δ-La0.9Sr0.1 Ga0.8Mg0.2O3 composite cathode thin film for SOFC by slurry spin coating. J Rare Earths 28:917–921

Hwang HJ, Moon J-W, Moon J, Awano M (2004) Removal of nitric oxide (NO) by perovskite-type composite catalytic thick film, La0.6Sr0.4Co0.2Fe0.8O3-δ and gadolinia-doped ceria electrolyte, Gd0.2Ce0.8O2-δ. J Am Ceram Soc 88:79–84

Hwang HJ, Moon J-W, Lee S, Lee EA (2005) Electrochemical performance of LSCF-based composite cathodes for intermediate temperature SOFCs. J Power Sources 145:243–248

Acknowledgments

The authors gratefully acknowledge financial support from Ministry of Education Malaysia under Exploratory Research Grant Scheme (Project Number: R.J130000.7842.4L104) and Fundamental Research Grant Scheme (Project Number: R.J130000.7809.4F282), and Universiti Teknologi Malaysia under Research University Grant Tier 1 (Project number: Q.J130000.2509.05H53). The authors also would like to thank Research Management Centre, Universiti Teknologi Malaysia, for the technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abd Mutalib, M., Othman, M.H.D., Aziz, M. et al. The influence of PEEK as a pore former on the microstructure of brush-painted LSCF cathodes. J Solid State Electrochem 20, 2895–2905 (2016). https://doi.org/10.1007/s10008-016-3300-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-016-3300-x