Abstract

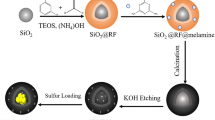

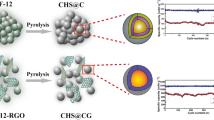

A hollow carbon microsphere (HC) material was synthesized by hydrothermal method, which could be used as a potential hard template. Active sulfur is encapsulated into the hollow carbon microspheres via simple impregnation and heat treatments to design a sulfur−hollow carbon microsphere (S−HC) composite with the novel yolk−shell structure. The hollow carbon shell, acts as a conductor to provide a highly conductivity and short Li+ diffusion distance, as well as absorbs polysulfides to improve the cycle ability of the S−HC composite in lithium sulfur (Li−S) batteries. The internal void space inside the shell can accommodate the volumetric expansion of sulfur during lithiation. The initial discharge capacity of S−HC cathode is as high as 1420 mA h g−1 at 0.1 C. After a 100 cycle stability test, the S−HC cathode exhibits still as high as 710 mA h g−1 at 0.2 C. Test results indicate that the S−HC composite is a promising host material for the sulfur cathode in the Li−S battery applications.

Similar content being viewed by others

References

Bruce PG, Freunberger SA, Hardwick LJ, Tarascon JM (2012) Nat Mater 11:19–29

Ji XL, Lee KT, Nazar LF (2009) Nat Mater 8:500–506

Suo L, Hu YS, Li H, Armand M, Chen L (2013) Nat Commun 4:1481–1489

Zhang YG, Zhao Y, Konarov A, Gosselink D, Soboleski HG, Chen P (2013) J Power Sources 241:517–521

Zhang C, Wu HB, Yuan C, Guo Z, Lou XW (2012) Angew Chem Int Ed 51:9592–9595

Li LY, Chen YX, Guo XD, Zhong BH, Zhong YJ (2014) Electrochim Acta 137:411–415

Zhang YG, Bakenov Z, Zhao Y, Konarov A, Doan TNL, Malik M, Paron T, Chen P (2012) J Power Sources 208:1–8

Zu C, Manthiram A (2013) Adv Energy Mater 3:1008–1012

Wang L, Wang D, Zhang FX, Jin J (2013) Nano Lett 13:4206–4211

Zhang YG, Bakenov Z, Zhao Y, Konarov A, Doan TNL, Sun KEK, Yermukhambetova A, Chen P (2013) Powder Technol 235:248–255

Song MS, Han SC, Kim HS, Kim JH, Kim KT, Kang YM, Ahn HJ, Dou SX, Lee JY (2004) J Electrochem Soc 151:A791–A795

Zhang YG, Zhao Y, Yermukhambetova A, Bakenov Z, Chen P (2013) J Mater Chem A 1:295–301

Evers S, Nazar LF (2013) Acc Chem Res 5:1135–1143

Cai K, Song MK, Cairns EJ, Zhang Y (2012) Nano Lett 12:6474–6479

Dörfler S, Hagen M, Althues H, Tübke J, Kaskel S, Hoffmann MJ (2012) Chem Commun 48:4097–4099

Xin S, Gu L, Zhao NH, Yin YX, Zhou LJ, Guo YG, Wan LJ (2012) J Am Chem Soc 134:18510–18513

Schuster J, He G, Mandlmeier B, Yim T, Lee KT, Bein T, Nazar LF (2012) Angew Chem Int Ed 51:3591–3595

Chen SR, Zhai YP, Xu GL, Jiang YX, Zhao D, Li JT, Huang L, Sun SG (2011) Electrochim Acta 26:9549–9555

Zheng SY, Chen Y, Xu Y, Yi F, Zhu Y, Liu Y, Yang J, Wang CS (2013) ACS Nano 7:10995–11003

Wang C, Wan W, Chen JT, Zhou HH, Zhang XX, Yuan LX, Huang YH (2013) J Mater Chem A 1:1716–1723

Zhou GM, Pei SF, Li L, Wang DW, Wang SG, Huang K, Yin LC, Li F, Cheng HM (2014) Adv Mater 26:625–631

Wang W, Li GC, Wang Q, Li GR, Ye SH, Gao XP (2013) J Electrochem Soc 160:A805–A810

Seh ZW, Li W, Cha JJ, Zheng G, Yang Y, McDowell MT, Hsu PC, Cui Y (2013) Nat Commun 4:1331–1337

Zhou WD, Yu YC, Chen H, DiSalvo FJ, Abruña HD (2013) J Am Chem Soc 135:16736–16743

White RJ, Tauer K, Antonietti M, Magdalena M (2010) J Am Chem Soc 132:17360–17363

Acknowledgments

This work was supported by the financial supports of the National Natural Science Foundation of China (Nos. 21,301,140 and 21,061,130,551), the Natural Science Foundation of Shaanxi Province (Nos. 2012JQ6019 and 2013JM2009), and the Xi’an Industrial Technology Innovation Project-technology transfer promoting program (No. CXY1438-7).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yuan, G., Wang, G., Wang, H. et al. A novel sulfur/carbon hollow microsphere yolk−shell composite as a high-performance cathode for lithium sulfur batteries. J Solid State Electrochem 19, 1143–1149 (2015). https://doi.org/10.1007/s10008-014-2710-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-014-2710-x