Abstract

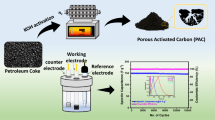

High-performance activated carbon for electrochemical double-layer capacitors (EDLC) has been prepared from cation exchange resin by carbonization and subsequent activation with KOH. The activation temperature has a key role in the determination of porous carbon possessing high surface areas, and large pore structures. The porous carbon activated at 700 °C (carbon-700-1:4) has high surface area (2236 m2 g−1) and large total pore volume (1.15 cm3 g−1), which also displays best capacitive performances due to its well-balanced micro- or mesoporosity distribution. In details, specific capacitances of the carbon-700-1:4 sample are 336.5 F g−1 at a current density of 1 A g−1 and 331.8 F g−1 at 2 A g−1. At high current density as 20 A g−1, the retention of its specific capacitance is 68.4 %. The carbon-700-1:4 sample also exhibits high performance of energy density (46.7 Wh kg−1) and long cycle stability (∼8.9 % loss after 3,000 cycles). More importantly, due to the amount of waste ion-exchange resins increasing all over the world, the present synthetic method might be adopted to dispose them, producing high-performance porous carbons for EDLC electrode materials.

Similar content being viewed by others

References

Gogotsi Y, Simon P (2011) Science 334:917–918

Kötz R, Carlen M (2000) Electrochim Acta 45:2483–2498

Simon P, Gogotsi Y (2008) Nat Mater 7:845–854

Frackowiak E, Béguin F (2001) Carbon 39:937–950

Nishihara H, Kyotani T (2012) Adv Mater 24:4473–4498

Xia Y, Yang Z, Mokaya R (2010) Nanoscale 2:639–659

Zhai Y, Dou Y, Zhao D, Fulvio PF, Mayes RT, Dai S (2011) Adv Mater 23:4828–4850

Wang J, Kaskel S (2012) J Mater Chem 22:23710–23725

Zhang LL, Zhao XS (2009) Chem Soc Rev 38:2520–2531

Zhu Y, Murali S, Stoller MD, Ganesh KJ, Cai W, Ferreira PJ, Pirkle A, Wallace RM, Cychosz KA, Thommes M, Su D, Stach EA, Ruoff RS (2011) Science 332:1537–1541

Xing W, Huang CC, Zhuo SP, Yuan X, Wang GQ, Hulicova-Jurcakova D, Yan ZF, Lu GQ (2009) Carbon 47:1715–1722

Lv Y, Zhang F, Dou Y, Zhai Y, Wang J, Liu H, Xia Y, Tu B, Zhao DY (2012) J Mater Chem 22:93–99

Yoon SH, Lim S, Song Y, Ota Y, Qiao W, Tanaka A, Mochida I (2004) Carbon 42:1723–1729

Li X, Han C, Chen X, Shi C (2010) Microporous Mesoporous Mater 131:303–309

Nakagawa H, Watanabe K, Harada Y, Miura K (1999) Carbon 37:1455–1461

Nezu A, Morishima T, Watanable T (2003) Thin Solid Films 435:335–339

Hu M, Reboul J, Furukawa S, Torad NL, Ji Q, Srinivasu P, Ariga K, Kitagawa S, Yamauchi Y (2012) J Am Chem Soc 134:2864–2867

Díaz-Terán J, Nevskaia DM, Fierro JLG, López-Peinado AJ, Jerez A (2003) Microporous Mesoporous Mater 60:173–181

Lillo-Ródenas MA, Cazorla-Amorós D, Linares-Solano A (2003) Carbon 41:267–275

Romanos J, Beckner M, Rash T, Firlej L, Kuchta B, Yu P, Suppes G, Wexler C, Pfeifer P (2012) Nanotechnol 23:015401

Yang S, Hu H, Chen G (2002) Carbon 40:277–284

Liang Y, Feng X, Zhi L, Kolb U, Müllen K (2009) Chem Commun (7):809–811

Li F, Morris M, Chan KY (2011) J Mater Chem 21:8880–8886

Radhakrishnan L, Reboul J, Furukawa S, Srinivasu P, Kitagawa S, Yamauchi Y (2011) Chem Mater 23:1225–1231

Jiang HL, Liu B, Lan YQ, Kuratani K, Akita T, Shioyama H, Zong F, Xu Q (2011) J Am Chem Soc 133:11854–11857

Okpalugo TIT, Papakonstantinou P, Murphy H, McLaughlin J, Brown NMD (2005) Carbon 43:153–161

Datsyuk V, Kalyva M, Papagelis K, Parthenios J, Tasis D, Siokou A, Kallitsis I, Galiotis C (2008) Carbon 46:833–840

Pevida C, Drage TC, Snape CE (2008) Carbon 46:1464–1474

Deitzel JM, Kosik W, McKnight SH, Beck Tan NC, DeSimone JM, Crette S (2002) Polymer 43:1025–1029

Yang D, Velamakanni A, Bozoklu G, Park S, Stoller M, Piner RD, Stankovich, Jung I, Field DA, Ventrice CA Jr, Ruoff RS (2009) Carbon 47:145–152

Coullerez G, Léonard D, Lundmark S, Mathieu HJ (2000) Surf Interface Anal 29:431–443

Lozano-Castelló D, Cazorla-Amorós D, Linares-Solano A, Shiraishi S, Kurihara H, Oya A (2003) Carbon 41:1765–1775

Fuertes AB, Lota G, Centeno TA, Frackowiak E (2005) Electrochim Acta 50:2799–2805

Chen LF, Zhang XD, Liang HW, Kong M, Guan QF, Chen P, Wu ZY, Yu SH (2012) ACS NANO 6:7092–7102

Kötz R, Hahn M, Gallay R (2006) J Power Sources 154:550–555

Acknowledgments

This work was supported by Anhui Province Key Laboratory of Environment-friendly Polymer Materials, Anhui University, Hefei 230039, China (KF2012009). Dr. Xiang Ying Chen also thanks the financial support from the National Natural Science Foundation of China (21101052) and China Postdoctoral Science Foundation (20100480045).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Figure S1

(a) Cyclic voltammograms at the scan rates of 50 mV s−1; (b) galvanostatic charge–discharge curves measured at the current density of 4 A g−1; (c) specific capacitances at various current densities; (d) cycling stability of the carbon samples. (DOC 881 kb)

Figure S2

(a) Ragone plots showing energy density vs. power density of the carbon samples; (b) Nyquist plots before/after 50 cycles of the carbon samples. (DOC 113 kb)

Rights and permissions

About this article

Cite this article

Zhang, Z.J., Cui, P., Chen, X.Y. et al. The production of activated carbon from cation exchange resin for high-performance supercapacitor. J Solid State Electrochem 17, 1749–1758 (2013). https://doi.org/10.1007/s10008-013-2039-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-013-2039-x