Abstract

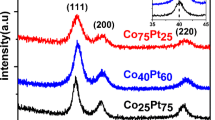

Platinum-rich CoPt films have been electrodeposited with the aim of preparing hard magnetic films on silicon-based substrates without the need for subsequent annealing. Electrodeposition conditions have permitted the crystalline structure of the films to be controlled. Pt percentages of up to 60–65 wt.% have been attained while maintaining the hexagonal Co phase, leading to CoPt films with moderate coercivity and good corrosion resistance. However, when low deposition potentials were used, CoPt films with higher Pt percentages were obtained, but in this case, the films exhibited an fcc structure, having lower coercivity and less corrosion resistance. The presence of hypophosphite in the solution limited the platinum percentage in the deposited CoPtP films, but an hexagonal close-packed (hcp) structure was always observed in this case. The incorporation of P into the deposits led to increases in both the coercivity of the films and the corrosion resistance of the coatings, with respect to pure CoPt. The highest coercivity was obtained for hcp CoPtP deposits with 40 wt.% of Pt.

Similar content being viewed by others

References

Casals-Terré J, Duch M, Plaza JA, Esteve J, Pérez-Castillejos R, Vallés E, Gómez E (2008) Sens Actuators, A, Phys 147:600

Osaka T, Sawaguchi T, Mizutani F, Yokoshima T, Takai M, Okinaka Y (1999) J Electrochem Soc 146:3295

Tabakovic I, Inturi V, Riemer S (2002) J Electrochem Soc 149:C18

Lallemand F, Comte D, Ricq L, Renaux P, Pagetti J, Dieppedale C, Gaud P (2004) Appl Surf Sci 225:59

Chin TS (2000) J Magn Magn Mater 209:75

Cho HJ, Ahn CH (2002) J Microelectromechanical Syst 11:78

Park DY, Myung NV, Schwartz M, Nobe K (2002) Electrochim Acta 47:2893

Myung NV, Park DY, Yoo BY, Sumodjo PTA (2003) J Magn Magn Mater 265:189

Niarchos D (2003) Sens Actuators A Phys 109:166

Guan S, Nelson BJ (2005) Sens Actuators A Phys 118:307

Guan S, Nelson BJ (2005) J Magn Magn Mater 292:49

Su Y, Wang H, Ding G, Cui F, Zhang W, Chen W (2005) IEEE Trans Magn 41:4380

Pigazo F, Palomares FL, Cebollada F, González JM (2008) J Magn Magn Mater 320:1966

Lew KS, Rajab M, Thanikaikarasan S, Kim T, Kim YD, Mahalingam T (2008) Mater Chem Phys 112:249

Pané S, Gómez E, Vallés E (2007) Electrochem Commun 9:1755

Xu QY, Kageyama Y, Suzuki T (2005) J Appl Phys 97:10K308

Chen XY, Jiang ZhL, Zhang L, Chen Y, Bai FM, Chen HM, Zhu J (2003) Mater Sci Forum 426:2381

Liu Y, Dallimore MP, McCormick PG, Alonso T (1992) Appl Phys Lett 60:3186

Pattanaik G, Kirkwood DM, Xu X, Zangari G (2007) Electrochim Acta 52:2755

Myung NY, Park DY, Schwartz M, Nobe K, Yang H, Yang CK, Judy JW (2000) Magnetic materials, processes and devices. In: Krongelb S, Romankiw LT, Ahn CH, Chang JW, Schwarzacher W (eds) The electrochemical society proceedings series. Electrochemical Society, Pennington

Zuzek-Rozman K, Krause A, Leistner K, Fähler S, Schultz L, Schlorb H (2007) J Magn Magn Mater 314:116

Cavallotti PL, Bestetti M, Franz S (2003) Electrochim Acta 48:3013

Zana I, Zangari G, Park JW, Allen MG (2004) J Magn Magn Mater 272–276:e1775

Lee KH, Kang SW, Kim GH, Jeung WY (2004) J Magn Magn Mater 272–276:e925

Park HD, Lee KH, Kim GH, Jeung WY (2006) J Appl Phys 99:08N305

Vieux-Rochaz L, Dieppedale C, Desloges B, Gamet D, Barragatti C, Rostaing H, Meunier-Carus J (2006) J Micromech Microeng 16:219

Cortés M, Matencio S, Gómez E, Vallés E (2009) J Electroanal Chem 627:69

Oliveira MC, do Rego AMB (2006) J Alloys Compd 425:64

Dulal SMSI, Kim TH, Shin CB, Kim CK (2008) J Alloys Compd 461:382

Cheonga WJ, Luana BL, Shoesmitha DW (2004) Appl Surf Sci 229:282

Homma T, Komatsu I, Tamaki A, Nakai H, Osaka T (2001) Electrochim Acta 47:47

Gómez E, Vallés E (2002) J Appl Electrochem 32:693

Boultif A, Loüer D (2004) J Appl Crystallogr 37:724

Cullity BD (1978) Elements of X-ray diffraction, 2nd edn. Addison-Wesley, Boston

García-Torres J, Gómez E, Vallés E (2009) J Appl Electrochem 39:233

Homma T, Sezai Y, Osaka T, Maeda Y, Donnet DM (1997) J Magn Magn Mater 173:314

Burchardt T, Hansen V, Valand T (2001) Electrochim Acta 46:2761

Jung H, Alfantazi A (2006) Electrochim Acta 51:1806

Acknowledgments

The authors wish to thank the Serveis Cientificotècnics (Universitat de Barcelona) and the Servei de Magnetoquímica (Universitat de Barcelona) for the use of their equipment. This paper was supported by contract MAT2006-12913-C02-01 from the Comisión Interministerial de Ciencia y Tecnología (CICYT).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cortés, M., Gómez, E. & Vallés, E. Magnetic properties of nanocrystalline CoPt electrodeposited films. Influence of P incorporation. J Solid State Electrochem 14, 2225–2233 (2010). https://doi.org/10.1007/s10008-010-1055-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-010-1055-3