Abstract

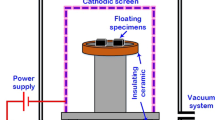

We report here on the synthesis of homogenous, well-adherent composite film of Fe2O3/SiO2, up to 7 μm thick, on the titanium substrate by anodic treatment optimized for an aqueous suspension of K2O·SiO2 and Fe2O3 powder under galvanostatic conditions. The end products were characterized by scanning electron microscopy, energy-dispersive X-ray, X-ray powder diffractometry, X-ray photoelectron spectroscopy, and Mössbauer spectroscopy, concluding that the formation of composite coating at the SiO2 to Fe2O3 ratio of approximately 1:1 proceeds just after formation of a thin TiO2 layer with Fe2O3 particle inclusions without transformations via an electrophoresis deposition of negatively charged Fe2O3 species enveloped by silica ions.

Similar content being viewed by others

References

Široky K, Jirešova J, Hudec LO (1994) Thin Solid Films 245:211. doi:10.1016/0040-6090(94)90902-4

Matijević E, Scheiner P (1978) J Colloid Interface Sci 63:509. doi:10.1016/S0021-9797(78)80011-3

Faust B, Hoffmann M, Bachnemann D (1989) J Phys Chem 93:6371. doi:10.1021/j100354a021

Gong C, Chen D, Jiao X, Wang Q (2002) J Mater Chem 12:1844. doi:10.1039/b201243j

Baltes M, Mathieu M, Vansant EF (2002) J Phys Chem B 106:13146. doi:10.1021/jp0211640

Park S, Lim S, Choi H (2006) Chem Mater 18:5150. doi:10.1021/cm0601990

Lee CW, Jung SS, Lee JS (2008) Mater Lett 62:561. doi:10.1016/j.matlet.2007.08.073

Zhang LY, Feng J, Xue DS (2007) Mater Lett 61:1363. doi:10.1016/j.matlet.2006.07.049

Gao CX, Liu QF, Xue DS (2002) J Mater Sci Lett 21:1781. doi:10.1023/A:1020941325311

Wang HW, Lin HC, Yeh YC, Kuo CH (2007) J Magn Magn Mater 310:2425. doi:10.1016/j.jmmm.2006.10.814

Suber L, Imperatori P, Ausanio G, Fabbri F, Hofmeister H (2005) J Phys Chem B 109:7103. doi:10.1021/jp045737f

Cornell RM, Schwertmann U (2003) The iron oxides, 2nd edn. Wiley-VCH, Weinheim

Kulkarni SS, Lokhande CD (2003) Mater Chem Phys 82:151. doi:10.1016/S0254-0584(03)00212-8

Choi KH, Lee SH, Kim YR, Malkinski L, Vovk A, Barnakov Y, Park JH, Jung YK, Jung JS (2007) J Magn Magn Mater 310:e861. doi:10.1016/j.jmmm.2006.11.022

Zou G, Xiong K, Jiang C, Li H, Li T, Du J, Qian Y (2005) J Phys Chem B 109:18356. doi:10.1021/jp052678c

Noorjahan M, Kumari VD, Subrahmanyam M, Boule P (2004) Appl Catal B 47:209. doi:10.1016/j.apcatb.2003.08.004

Sakthivel S, Shankar MV, Palanichamy M, Arabindoo B, Murugesan V (2002) J Photochem Photobiol A 148:153. doi:10.1016/S1010-6030(02)00085-0

Zhang RB (2005) J Non-Cryst Solids 351:2129. doi:10.1016/j.jnoncrysol.2005.04.048

Gao Y, Liu H (2005) Mater Chem Phys 92:604. doi:10.1016/j.matchemphys.2005.02.018

Geus JW (1986) Appl Catal 25:313. doi:10.1016/S0166-9834(00)81249-X

Huo L, Li W, Lu L, Cui H, Xi S, Wang J, Zhao B, Shen Y, Lu Z (2000) Chem Mater 12:790. doi:10.1021/cm990690+

Ohmori T, Takahashi H, Mametsuka H, Suzuki E (2000) Phys Chem Chem Phys 2:3519. doi:10.1039/b003977m

Catti M, Valerio G, Dovesi R (1995) Phys Rev B 51:7441. doi:10.1103/PhysRevB.51.7441

Hansen MF, Koch CB, Mørup S (2000) Phys Rev B 62:1124. doi:10.1103/PhysRevB.62.1124

Xu X, Wang J, Yang C, Wu H, Yang FJ (2009) Alloys Compd 468:414. doi:10.1016/j.jallcom.2008.01.013

Philipse AP, Bruggen MPB, Pathmamanoharan C (1994) Langmuir 10:92. doi:10.1021/la00013a014

Solinas S, Piccaluga G, Morales MP, Serna CJ (2001) Acta Mater 49:2805. doi:10.1016/S1359-6454(01)00160-4

Lu Y, Yin YD, Brian TM, Xia YN (2002) Nano Lett 2(3):183. doi:10.1021/nl015681q

Malyshev VN, Zorin KM (2007) Appl Surf Sci 254:1511. doi:10.1016/j.apsusc.2007.07.079

Wagner CD, Riggs WM, Davis LE, Moulder JF, Muilenberg GE (1978) Handbook of X-ray photoelectron spectroscopy. Perkin-Elmer, Minnesota

Patel MN, Williams RD, May RA, Uchida H, Stevenson KJ, Johnston KP (2008) Chem Mater 20:6029. doi:10.1021/cm8012705

Yerokhin AL, Nie X, Leyland A, Matthews A (2000) Surf Coat Technol 130:195. doi:10.1016/S0257-8972(00)00719-2

Somasundaran P (ed) (2006) Encyclopaedia of surface and colloid science. Taylor & Francis, New York, p 1857

Acknowledgments

This research was in part supported by a grant from the Lithuanian State Science and Studies Foundation (C-07035). The authors are grateful to Remigijus Juškėnas from the Institute of Chemistry for assistance in XRD spectroscopy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jagminas, A., Ragalevičius, R., Mažeika, K. et al. A new strategy for fabrication Fe2O3/SiO2 composite coatings on the Ti substrate. J Solid State Electrochem 14, 271–277 (2010). https://doi.org/10.1007/s10008-009-0820-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-009-0820-7