Abstract

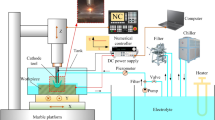

An ITO layer is produced using semiconductor techniques, although the defect rate during production is easily seen. Current work presents a new modus of electrochemical machining using a ‘design recycle’ system offering faster performance in removing the color filter surface’s ITO layer. Higher electrical current is not required when an effective feeding electrode is used to reduce the response area. Through establishing an ultra-precise recycling process to remove the thin film microstructure, this helps the semiconductor optoelectronic industry to reduce both production costs and pollution. The design features of the removal processes for a thin film and the tool design of plate-form electrode are of major interest. In the current experiment, the author utilizes a 5th Generation TFT-LCD. The design of tool electrodes is used with continuous and pulsed direct current in the electrochemical machining experiment. High rotational speed of the tool electrodes and high flow velocity of the electrolyte elevates the discharge mobility and improves the removal effect. Pulsed direct current can improve the effect of dregs discharge and is advantageous to associate with the fast feed rate of the workpiece. A color filter with a fast feed rate is combined with enough electric power to provide highly effective removal. A smaller end radius and a thin plate-form positive-electrode provide a larger discharge space and better removal effect. A precision recycling process is presented using an effective plate-form positive-electrode in electrochemical machining. It only needs a short period of time to remove the ITO layer easily and cleanly.

Similar content being viewed by others

References

Shima T, Itakura T, Minamizaki, H, Maruyama T (1997) Proc Int ISSCC’, Kawasaki, Japan 97:192

Avenel E, Barlet C (2000) J Econ Manage Strategy 9(3):211

Takabatake M, Ohwada J, Ono YA, Ono K, Mimura A, Konishi, N (1991) IEEE Trans Electron Devices 38(6):1303

Guh HS (2004) MNew Wun Ching Developmental Publishing Co., Ltd., Taiwan

Biai I, Quinteda M, Mendes, L et al (1999) Int’l J Thin Solid Films 337:171

Kim H-C, Kwon B-H, Choi M-R (2001) IEEE Trans Electron 47

Daeil K, Steven K (2002) Int’l J Surf Coat Technol 154:204

Lee P, Chen H (2005) IEEE Conference Proceeding 1:780

Wilson J (1971) Wile-Interscience. New York, NY, 79

Phillips RE (1996) Carbide Tool J 18(6):12

Mileham AR, Harrey SJ, Stout KJ (1986) The Characterization of Electrochemically Machined Surfaces, Wear 109:207

McGeough JA (1974) Principles of electrochemical machining. Chapman & Hall, London

Bannard J (1977) J Appl Electrochem 7:267

Datta M, Landolt D (1983) J Appl Electrochem 13:795

Shen WM (1995) M.Sc. Thesis, National Yunlin Institute of Techndogy, Taiwan

Mansour SS (1980) I A S; Sedahmed, G H Surface Technol 10(5):357

Datta M, Landolt D (1981) Elector Acta 26(7):899

Rajurkar KR (1995) Annals of the CIRP 44:177

Cagnon L, Kirchner V, Kock M, Schuster R, Ertl G, Gmelin WT, Kuck, H (2003) Z Phys Chem 217:299

Jain VK, Yogindra, PG, Murugan S (1987) Int J Mach Tools Manufact 27(1):1135

Hocheng H, Pa PS (2002) 120:6

Hocheng H, Pa PS (2003) J Mater Process Technol 142(1):203

Hocheng H, Pa PS (2004) 20(4):312

Pa PS (2006) Mater Sci Forum 5:32–533:965

Kim BH, Ryu SH, Choi, SH, Chu CN (2005) J Micromechanics and Microengineering 15:124

Acknowledgement

The current study is supported by BEN TEN THE CO., The current study is supported by National Science Council, contract 95-2622-E-152-001-CC3 and 95-2622-E-152-001-CC3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pa, P.S. Precision removal of ITO layer using plate-form tool design. J Solid State Electrochem 12, 1445–1451 (2008). https://doi.org/10.1007/s10008-007-0492-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-007-0492-0