Abstract

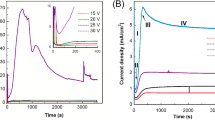

A procedure based on the high-field mechanism of the growth of anodic oxides was developed in order to evaluate the morphological features of porous layers. Since the thickness of the barrier film, separating the porous layer from the metal, does not change during the steady-state growth of an anodic porous layer, the rate of displacement of the metal-oxide interface to the metal direction must be equal to the rate of displacement of the pore base to the oxide direction. As a consequence, porosity can be expressed in terms of the ratio i diss/i ion, where i diss is the dissolution current density at the pore base, and i ion is the ionic current density at the metal-oxide interface. Pore diameter can be determined from geometrical considerations, while average pore population can be obtained from the ratio of porosity to the average surface area of a single pore. This procedure was checked by comparison with experimental results relative to membranes prepared in various conditions. The satisfactory agreement between theoretical and experimental findings indicates that porosity can be evaluated by current density data and vice-versa. Therefore, anodic alumina membranes may be tailored for different applications by choosing operative conditions giving the desired value of i diss/i ion.

Similar content being viewed by others

References

Henley VF (1982) Anodic oxidation of aluminium and its alloys. Pergamon, Oxford

Furneaux RC, Rigby WR, Davidson AP (1989) Nature 337:147

Asoh H, Nishio K, Nakao M, Tamamura T, Masuda H (2001) J Electrochem Soc 148:B152

Kovtyukhova NI, Mallouk TE, Mayer TS (2003) Adv Mater 15:780

Julbe A, Farrusseng D, Guizard C (2001) J Membr Sci 181:3

Bocchetta P, Sunseri C, Masi R, Piazza S, Di Quarto F (2003) Mater Sci Eng C 23:1021

Jessennsky O, Müller F, Gösele U (1998) Appl Phys Lett 72:1173

Masuda H, Yamada Y, Satoh M, Asoh H, Naka M, Tamamura T (1997) Appl Phys Lett 71:2770

Bocchetta P, Sunseri C, Bottino A, Capannelli G, Chiavarotti G, Piazza S, Di Quarto F (2002) J Appl Electrochem 32:977

Bocchetta P, Sunseri C, Chiavarotti G, Di Quarto F (2003) Electrochim Acta 48:3175

O’Sullivan JP, Wood GC (1970) Proc Roy Soc Lond A 317:511

Siejka J, Ortega C (1977) J Electrochem Soc 124:883

Shimizu K, Kobayashi K, Thompson GE, Wood GC (1992) Phil Mag 66:643

Patermarakis G (1996) J Electroanal Chem 404:69

Bernard WJ, Cook JW (1959) J Electrochem Soc 106:643

Harkness AC, Young L (1966) Can J Chem 44:2409

Wehrspohn RB, Nielsch K, Birner A, Schilling J, Muller F, Li A-P, Gosele U (2001) Electrochemically prepared high-aspect ratio highly ordered pore arrays and applications. In: Schmuki P, Lockwood DJ, Ogata YH, Isaacs HS (eds) Pits and pores II: formation properties, and significance for advanced materials, vol 2000–25, The Electrochemical Society, Inc., Pennington, NJ, pp 168–175

Wernick S, Pinner R, Sheasby PG (1987) The surface treatment and finishing of aluminium and its alloys, 5th edn, vol 1 ASM International, Finishing Publications LTD. Teddington, Middlesex, England

Acknowledgements

The authors gratefully acknowledge financial support from MIUR – Cofin 2002

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sunseri, C., Spadaro, C., Piazza, S. et al. Porosity of anodic alumina membranes from electrochemical measurements. J Solid State Electrochem 10, 416–421 (2006). https://doi.org/10.1007/s10008-005-0012-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-005-0012-z