Abstract

Elucidating the mechanical response of diamond is a difficult task due to its ultrahard nature. Here, we applied a molecular dynamics (MD) method to investigate the mechanical response of single-crystal diamond under nanoindentation. There was no obvious “pop in” phenomenon on the load–depth curve, and the elastic modulus deduced from the curve was 1128 GPa, which was similar to the value obtained from experimental measurements. Results from computed tomography (CT) and the coordination number showed that the distribution of the mismatched C atoms around the deformation zone took the form of a ‘double cross.’ The atoms around the indenter tip could be divided into two zones, a translation zone and a lattice distortion zone, based on their movements. Subsequent first-principles calculations revealed that the C-atom displacement barrier varied significantly with direction, which resulted in shear stress between the two zones and the formation of the double-cross splitting.

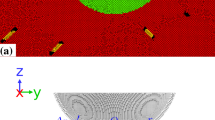

The displacement of the atoms around the indenter tip

Similar content being viewed by others

References

Li Y, Jia X, Yan B, Chen N, Fang C, Li Y, Sun S, Ma H (2016) Influence of carbon convection field on high quality large single crystal diamonds morphology under high pressure and high temperature. RSC Adv 6:40330–40335

Liang Q, Yan C, Meng Y, Lai J, Krasnicki S, Mao H, Hemley JR (2009) Enhancing the mechanical properties of single-crystal CVD diamond. J Phys Condens Matter 21:364215

Saurav G, Luo X, Robert LR (2013) Wear mechanism of diamond tools against single crystal silicon in single point diamond turning process. Tribo Intl 57:272–281

Burek JM, Leon PN, Shields JB, Hausmann JMB, Chu Y, Quan Q, Zibrov SA, Park H, Lukin DM, Loncar M (2012) Free-standing mechanical and photonic nanostructures in single-crystal diamond. Nano Lett 12:6084–6089

Fazio LD, Syngellakis S, Wood RJK, Fuginuele FM, Sciumé G (2001) Nanoindetation of CVD diamond, comparison of an FE model with analytical and experimental data. Diam Relat Mater 10:765–769

Zhang L, Ohmura T (2014) Plasticity initiation and evolution during nanoindentation of an iron–3% silicon crystal. Phys Rev Lett 112:145504

Wang CH, Fang TH, Cheng PC, Chiang CC, Chao KC (2015) Simulation and experimental analysis of nanoindentation and mechanical properties of amorphous NiAl alloys. J Mol Model 21:161

Minor AM, Asif SAS, Shan Z, Stach EA, Cyrankowski E, Wyrobek TJ, Warren OL (2006) A new view of the onset of plasticity during the nanoindentation of aluminium. Nat Mater 5:697

Richter A, Ries R, Smith R, Henkel M, Wolf B (2000) Nanoindentation of diamond, graphite and fullerene films. Diam Relat Mat 9:170–184

Fan X, Nose K, Diao D, Yoshida T (2013) Nanoindentation behaviors of amorphous carbon films containing nanocrystalline graphite and diamond clusters prepared by radio frequency sputtering. Appl Surf Sci 273:816–823

Sinnott SB, Colton RJ, White CT, Shenderova OA, Brenner DW, Harrison JA (1997) Atomistic simulations of the nanometer-scale indentation of amorphous-carbon thin films. J Vac Sci Technol A 15:936

Wiora M, Brühne K, Flöter A, Gluche P, Willey TM, Kucheyev SO, Van Buuren AW, Hamza AV, Biener J, Fecht HJ (2009) Grain size dependent mechanical properties of nanocrystalline diamond films grown by hot-filament CVD. Diam Relat Mat 18:927–930

Veprek-Heijman MGJ, Veprek GR, Argon AS, Parks MD, Veperk S (2009) Nonlinear finite element constitutive modeling of indentation into super and ultrahard materials: the plastic deformation of the diamond tip and the ratio of hardness to tensile yield strength of super and ultrahard nanocomposites. Surf Coat Technol 203:3385–3391

Paul W, Oliver D, Miyahara Y, Grütter HP (2013) Minimum threshold for in cipient plasticity in the atomic-scale nanoindentation of Au(111). Phys Rev Lett 110:135506

Zhuang C, Zheng Q (2016) QM/MM calculations and MD simulations of acetolactate decarboxylase to reveal substrate R/S-acetolactate binding mode and stereoselective catalytic mechanism. RSC Adv 6:91852–91859

Xue Q, Tao Y, Liu Z, Lu S, Li X, Wu T, Jin Y, Liu X (2015) Mechanism of oil molecules transportation in nano-sized shale channel: MD simulation. RSC Adv 5:25684–25692

Toda N, Kimizuka H, Ogata S (2010) DFT-based FEM analysis of nonlinear effects on indentation process in diamond crystal. Intl J Mech Sci 52:303–308

Liu J, Zeng Q, Zhang Y, Zhang CY (2016) A limited sample coarse-grained strategy and its applications to molecular crystals: elastic property prediction and nanoindentation simulations of 1,3,5-trinitro-1,3,5-triazinane. J Phys Chem C 120:15198–15208

Mathew N, Sewell DT (2016) Nanoindentation of the triclinic molecular crystal 1,3,5-triamino-2,4,6-trinitrobenzene: a molecular dynamics study. J Phys Chem C 120:8266–8277

Lin Y, Chen T, Yang P, Jian S, Lai Y (2007) Atomic-level simulation of nanoindentation induced phase transformation in mono-crystalline silicon. Appl Surf Sci 254:1415–1422

Hoover WG (1985) Canonical dynamics: equilibrium phase-space distributions. Phys Rev A 31:1695

Nosé S (1984) A unified formulation of constant temperature molecular dynamics methods. J Chem Phys 81:511

Tersoff J (1986) New empirical model for the structural properties of silicon. Phys Rev Lett 56:632–635

Tersoff J (1988) New empirical approach for the structure and energy of covalent systems. Phys Rev B 37:6991–7000

Tersoff J (1988) Empirical interatomic potential for carbon, with applications to amorphous carbon. Phys Rev Lett 61:2879–2882

Tersoff J (1988) Empirical interatomic potential for silicon with improved elastic properties. Phys Rev B 38:9902–9905

Erhart P, Albe K (2005) Analytical potential for atomistic simulations of silicon, carbon, and silicon carbide. Phys Rev B 71:035211

Liu Y, Inamura T, Takezawa N (2006) MD simulation of ultra-micro cutting of monocrystalline silicon with effects of air. JSME Int J Ser C 49:70–75

Fang F, Wu H, Liu Y (2005) Modelling and experimental investigation on nano-metric cutting of monocrystalline silicon. Int J Mach Tool Manu 45:1681–1686

Cai M, Li X, Rahman M (2007) Study of the mechanism of groove wear of the diamond tool in nanoscale ductile mode cutting of monocrystalline silicon. J Manuf Sci Eng 129:281–286

Zhou M, Ngoi BKA, Wang X (2003) Tool wear in ultra-precision diamond cutting of non-ferrous metals with a round-nose tool. Tribol Lett 15:211–216

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117:1–19 (also see http://lammps.sandia.gov/)

Li J (2003) Atomeye: an efficient atomistic configuration viewer. Modell Simul Mater Sci Eng 11:173–177

Stukowski A (2010) Visualization and analysis of atomistic simulation data with OVITO—the open visualization tool. Modell Simul Mater Sci Eng 18:015012 (also see http://www.ovito.org/)

Liu W, Wang Y, Ma Y, Yu Q, Huang Y (2016) Nanoindentation study on micromechanical behaviors of Au–Ni–Sn intermetallic layers in Au–20Sn/Ni solder joints. Mat Sci Eng A 653:13–22

Zhou X, Ouyang B, Curtin WA, Song J (2016) Atomistic investigation of the influence of hydrogen on dislocation nucleation during nanoindentation in Ni and Pd. Acta Mater 116:364–369

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Savvides N, Bell TJ (1992) Microhardness and Young’s modulus of diamond and diamondlike carbon films. J Appl Phys 72:2791

Brookes CA, Brookes EJ (1991) Diamond in perspective: a review of mechanical properties of natural diamond. Diam Relat Mater 1:13–17

Rabier J, Cordier P, Demenet JL, Garem H (2001) Plastic deformation of Si at low temperature under high confining pressure. Mater Sci Eng A 74:309–310

Kavner A, Duffy TS (2001) Pressure–volume–temperature paths in the laser-heated diamond anvil cell. J Appl Phys 89:1907–1914

Meade C, Jeanloz R (1990) The strength of mantle silicates at high pressures and room temperature: implications for the viscosity of the mantle. Nature 348:533–535

Han J, Xu S, Sun J, Fang L, Zhu H (2017) Pressure-induced amorphization in the nanoindentation of single crystalline silicon. RSC Adv 7:1357–1362

Acknowledgements

We are very grateful for the financial support from the National Natural Science Foundation of China (11572296).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

The figures of a blunter indenter and it’s CT graph. (DOCX 338 kb)

Rights and permissions

About this article

Cite this article

Wang, L., Ke, H., Ma, J. et al. Investigation of the ‘double cross’ splitting mechanism of single-crystal diamond under nanoindentation via molecular dynamics simulation. J Mol Model 23, 299 (2017). https://doi.org/10.1007/s00894-017-3467-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00894-017-3467-9