Abstract

Objectives

Primary healing of dental implants is influenced by their surface morphology. However, little is known about any alterations in morphology during their insertion. Therefore, the aim of this study was to evaluate the surface morphology of four different implant systems, following their insertion in porcine jaw bones.

Methods

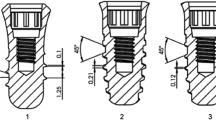

Four fresh porcine mandible specimens were used. Six new implants of four systems (Ankylos® 4.5 × 14 mm, Frialit Synchro® 4.5 × 15 mm, NobelReplace ® Tapered Groovy RP 4.3 × 13 mm, Straumann SLA® Bone Level 3.3 × 14 mm) were inserted, whereas one implant of each system served as a control. After their removal, implants were cleaned in an ultrasonic bath. All 28 implants were examined quantitatively by 3D confocal microscopy for surface characteristics.

Results

In the evaluated zones, implants of the Ankylos, Frialit, and Straumann systems showed mostly a reduction of the mean surface roughness Sa, the maximal surface roughness Sz, and the developed surface area ratio Sdr; Nobel implants showed an increase in these parameters. With respect to all three parameters Sa, Sz, and Sdr, statistical analysis revealed that differences between the four systems were highly significant in the apical region of implants. Controls showed no morphologic alterations.

Conclusion

The insertion process had an impact on the surface of all four implant systems. Anodized implant surface modification seems to result in more alterations compared with subtractive surface modifications. Therefore, surgical planning should take into consideration the choice of surface treatment because the characteristics of the implants may be modified during the installation process.

Clinical relevance

The given information is of value for daily implantation practice and the course of osseointegration.

Similar content being viewed by others

References

Thomason JM et al (2009) Mandibular two implant-supported overdentures as the first choice standard of care for edentulous patients—the York consensus statement. Br Dent J 207(4):185–186

Mints D et al (2014) Integrity of implant surface modifications after insertion. Int J Oral Maxillofac Implants 29(1):97–104

Albrektsson T et al (1981) Osseointegrated titanium implants. Requirements for ensuring a long-lasting, direct bone-to-implant anchorage in man. Acta Orthop Scand 52(2):155–170

Ruger M et al (2010) The removal of Al2O3 particles from grit-blasted titanium implant surfaces: effects on biocompatibility, osseointegration and interface strength in vivo. Acta Biomater 6(7):2852–2861

Mata A et al (2003) Osteoblast attachment to a textured surface in the absence of exogenous adhesion proteins. IEEE Trans Nanobioscience 2(4):287–294

Choi JW et al (2006) Biological responses of anodized titanium implants under different current voltages. J Oral Rehabil 33(12):889–897

Deppe H et al (2015) Surface morphology analysis of dental implants following insertion into bone using scanning electron microscopy: a pilot study. Clin Oral Implants Res 26(11):1261–1266

Pawley J (2006) Handbook of biological confocal microscopy, 3rd edn. Springer, Berlin

Sartoretto SC et al (2015) Early osseointegration driven by the surface chemistry and wettability of dental implants. J Appl Oral Sci 23(3):279–287

Wennerberg A, Albrektsson T (2000) Suggested guidelines for the topographic evaluation of implant surfaces. Int J Oral Maxillofac Implants 15(3):331–344

Arvidsson A, Sater BA, Wennerberg A (2006) The role of functional parameters for topographical characterization of bone-anchored implants. Clin Implant Dent Relat Res 8(2):70–76

Brown CA, Johnsen WA, Hult KM (1998) Scale-sensitivity, fractual analysis and simulations. Int J Mach Tools Manufact 38:633–637

Misch CE (1999) Bone density: a key determinant for clinical success. In: Misch CE (ed) Contemporary implant dentistry, 2nd edn. CV Mosby Company, St Louis

Cooper LF (2000) A role for surface topography in creating and maintaining bone at titanium endosseous implants. J Prosthet Dent 84(5):522–534

Trisi P et al (2003) Bone-implant contact on machined and dual acid-etched surfaces after 2 months of healing in the human maxilla. J Periodontol 74(7):945–956

Pak HS, Yeo IS, Yang JH (2010) A histomorphometric study of dental implants with different surface characteristics. J Adv Prosthodont 2(4):142–147

Bouwman JP, Tuinzing DB, Kostense PJ (1994) A comparative in vitro study on fixation of sagittal split osteotomies with Wurzburg screws, Champy miniplates, and biofix (biodegradable) rods. Int J Oral Maxillofac Surg 23(1):46–48

Mosekilde L (1995) Assessing bone quality—animal models in preclinical osteoporosis research. Bone 17(4 Suppl):343S–352S

Wennerberg A et al (1995) A histomorphometric and removal torque study of screw-shaped titanium implants with three different surface topographies. Clin Oral Implants Res 6(1):24–30

Ballo AM et al (2011) Dental implant surfaces—physicochemical properties, biological performance, and trends. In: Turkyilmaz PI (ed) Implant dentistry—a rapidly evolving practice. InTech

Albrektsson T, Wennerberg A (2004) Oral implant surfaces: part 1—review focusing on topographic and chemical properties of different surfaces and in vivo responses to them. Int J Prosthodont 17(5):536–543

Wennerberg A et al (1992) An optical three-dimensional technique for topographical descriptions of surgical implants. J Biomed Eng 14(5):412–418

Wennerberg A et al (1997) A 1-year follow-up of implants of differing surface roughness placed in rabbit bone. Int J Oral Maxillofac Implants 12(4):486–494

Wennerberg A, Albrektsson T, Andersson B (1996) Bone tissue response to commercially pure titanium implants blasted with fine and coarse particles of aluminum oxide. Int J Oral Maxillofac Implants 11(1):38–45

Wennerberg A et al (2004) Titanium release from implants prepared with different surface roughness. Clin Oral Implants Res 15(5):505–512

Valente ML, Lepri CP, dos Reis AC (2014) In vitro microstructural analysis of dental implants subjected to insertion torque and pullout test. Braz Dent J 25(4):343–345

Guan H et al (2009) Influence of bone and dental implant parameters on stress distribution in the mandible: a finite element study. Int J Oral Maxillofac Implants 24(5):866–876

Schliephake H et al (1993) Metal release from titanium fixtures during placement in the mandible: an experimental study. Int J Oral Maxillofac Implants 8(5):502–511

Goodman SB, Ma T (2010) Cellular chemotaxis induced by wear particles from joint replacements. Biomaterials 31(19):5045–5050

Bukata SV et al (2004) PGE2 and IL-6 production by fibroblasts in response to titanium wear debris particles is mediated through a Cox-2 dependent pathway. J Orthop Res 22(1):6–12

Tanaka M et al (1994) Effects of bone tapping on osseointegration of screw dental implants. Int J Oral Maxillofac Implants 9:541–547

Funding

The work was not funded.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

For this type of study, formal consent is not required.

Rights and permissions

About this article

Cite this article

Deppe, H., Wolff, C., Bauer, F. et al. Dental implant surfaces after insertion in bone: an in vitro study in four commercial implant systems. Clin Oral Invest 22, 1593–1600 (2018). https://doi.org/10.1007/s00784-017-2262-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-017-2262-4