Abstract

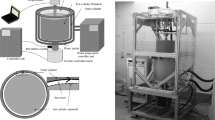

On the surface of a ship’s hull, roughness due to paint has significant effects on the ship’s resistance. In the ship design stage, the roughness resistance coefficient, ∆Cf, is commonly estimated by the ITTC1978 formula using Ks as a roughness parameter. Ks is also known as the average hull roughness, which is composed of the average of the Pt50 (the difference between the maximum peak height and the maximum valley depth in an evaluation length of 50 mm) values collected from multiple locations on the ship’s hull, using the BSRA hull roughness analyzer. The analyzer has been widely used because it is simple and easy to use and suitable at actual shipbuilding sites. However, this analyzer is only able to measure Pt50 values. In past studies, it has been indicated that not only the roughness height parameter but also wavelength parameter can affect friction resistance. Hence, here we have developed a new portable roughness measurement device that can measure various parameters, including the wavelength, and obtain three-dimensional (3D) profile images. This newly developed portable roughness analyzer can compile a large quantity of 3D images of surface roughness and calculate various parameters from the measured roughness profiles.

Similar content being viewed by others

References

MEPC (2011) Amendments to the annex of the protocol of 1997 to amend the international convention for the prevention of pollution from ships, 1973, as modified by the protocol of 1978 relating thereto (Inclusion of regulations on energy efficiency for ships in MARPOL Annex VI) MEPC 62/34/Add.1 Annex 19

MEPC (2012) Guide lines on survey and certification of the energy efficiency design index (EEDI). MEPC 63/23/Add.1 Annex 10

Nikuradse J (1933) Laws of flow in rough pipes. Forschungsheft 361

ITTC (1978) Performance, Proulsion 1978 ITTC performance prediction method. ITTC-Recommended Procedures. 7.5-02-3-01.4

Bowden BS, Davison NJ (1974) Resistance increments due to hull roughness associated with form factor extrapolation methods. National Maritime Institute Ship Technical Memo 380

Townsin RL, Byrne D, Svensen TE, Milne A (1981) Estimating the technical and economic penalties of hull and propeller roughness. Trans SNAME 89:295–318

Sasajima H, Terao T, Yoko K, Nakato M (1965) Experimental investigation into roughness of hull surface and increase of skin frictional resistance. J Japan Soc Nav Archit Ocean Eng 117:58–71

Denny ME (1951) BSRA resistance experiments on the ‘Lucy Ashton’: part 1. Full scale measurements. Trans Inst Nav Archit 93:40–57

Nace International (2016) Standard for hull roughness measurement for ship hulls in dry dock. Nace Standards

ISO (1997) Geometrical product specifications (GPS)-surface texture: profile method: terms, definitions and surface texture parameters. ISO 4287

ISO (1997) Geometrical product specifications (GPS)-surface texture: profile method: metrological characteristics of phase correct filters. ISO 11562

ISO (1996) Geometrical product specifications (GPS)-surface texture: profile method: rules and procedures for the assessment of surface texture. ISO 4288

Candries M, Atlar M (2003) On the drag and roughness characteristics of antifoulings. Int J Marit Eng 145(A2):36–60

Mieno H (2018) Three-dimensional surface roughness evaluating device, three-dimensional surface roughness evaluating method, three-dimensional surface roughness data acquiring device, and three-dimensional surface roughness data acquiring method. WIPO WO/2018/021210

Acknowledgements

This research has started with a feasibility study project of Japan Ship Machinery and Equipment Association. The project could not have been accomplished without great support and corporation of Professor Yasuyuki Toda of Osaka University, Professor Yasuo Kawaguchi of Tokyo university of Science, Professor Kaoru Iwamoto of Tokyo University of Agriculture and Technology, and Mr. Hideki Kawashima and Mr. Hiromoto Ando of National Maritime Research Institute. The research then continued to be carried out for the project “Next generation environmental related technology development support program” of Japanese Ministry of Land, Infrastructure, Transport and Tourism, and as a joint research with ClassNK, both entitled “Method to estimate the changing ratio of in situ friction resistance using the data of reduced surface roughness and roughness parameters of hull coating”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

About this article

Cite this article

Mieno, H., Katsui, T. Development of a portable 3D hull roughness analyzer. J Mar Sci Technol 25, 498–509 (2020). https://doi.org/10.1007/s00773-019-00656-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00773-019-00656-x