Abstract

The objective of this study was to estimate the strength and deformability of corroded steel plates under quasi-static uniaxial tension. In order to accurately simulate this problem, we first estimated the true stress–strain relationship of a flat steel plate by introducing a vision sensor system to the deformation measurements in tensile tests. The measured true stress–stain relationship was then applied to a series of nonlinear implicit three-dimensional finite element analyses using commercial code LS-DYNA. The strength and deformability of steel plates with various pit sizes, degrees of pitting intensity, and general corrosion were estimated both experimentally and numerically. The failure strain in relation to the finite element mesh size used in the analyses was clarified. Two different steels having yield ratios of 0.657 and 0.841 were prepared to examine the material effects on corrosion damage. The strength and deformability did not show a clear dependence on the yield ratios of the present two materials, whereas a clear dependence was shown with respect to the surface configuration such as the minimum cross-sectional area of the specimens, the maximum depth of the pit cusp from the mean corrosion diminution level, and pitting patterns. Empirical formulae for the reduction of deformability and the reduction of energy absorption of pitted plates were proposed which may be useful in strength assessment when examining the structural integrity of aged corroded structures.

Similar content being viewed by others

References

ISSC (2006) Committee Report V.6. Condition assessment of aged ships. In: Proceedings of the 16th international ship and offshore structures congress. University of Southampton, England, pp 255–307

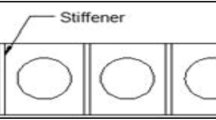

Nakai T, Matsushita H, Yamamoto N, Arai H (2004) Effect of pitting corrosion on local strength of hold frame of bulk carriers (1st report). Mar Struct 17:403–432

Sumi Y (2008) Strength and deformability of corroded steel plates estimated by replicated specimens. J Ship Prod 24–3:161–167

Paik JK, Lee JM, Ko MJ (2003) Ultimate strength of plate elements with pit corrosion wastage. J Eng Marit Environ 217:185–200

Paik JK, Lee JM, Ko MJ (2004) Ultimate shear strength of plate elements with pit corrosion wastage. Thin Wall Struct 42:1161–1176

Yamamoto N (2008) Probabilistic model of pitting corrosion and the simulation of pitted corroded condition. In: Proceedings of the ASME 27th international conference of offshore mechanics and arctic engineering. Estoril, Portugal, OMAE2008-57623

Yamamoto N, Ikegami K (1998) A study on the degradation of coating and corrosion of ship’s hull based on the probabilistic approach. J Offshore Mech Arct Eng 120:121–127

Bannister AC, Ocejo JR, Gutierrez-Solana F (2000) Implications of the yield stress/tensile stress ratio to the SINTAP failure assessment diagrams for homogeneous materials. Eng Fract Mech 67(6):547–562

Zang ZL, Hauge M, Ødegård J, Thaulow C (1999) Determining material true stress–strain curve from tensile specimens with rectangular cross-section. Int J Solids Struct 36:3497–3516

Scheider I, Brocks W, Cornec A (2004) Procedure for the determination of true stress–strain curves from tensile tests with rectangular cross-sections. J Eng Mater Technol 126:70–76

Bridgman PW (1964) Studies in large plastic flow and fracture. Harvard University Press, Cambridge

Ostsemin AA (1992) Stress in the least cross section of round and plane specimens. Strength Mater 24(4):298–301

Cabezas EE, Celentano DJ (2004) Experimental and numerical analysis of the tensile test using sheet specimens. Finite Elem Anal Des 40(5–6):555–575

Hallquist JO (2006) LS-DYNA theoretical manual. Livermore Software Technology Corporation, Livermore

Robert McNeel and Associates (2003) Rhinoceros user guide: NURBS modeling for windows. Version 3.0, McNeel, Seattle

Nakai T, Sumi Y, Saiki K, Yamamoto N (2006) Stochastic modeling of pitting corrosion and tensile tests with artificially pitted members (in Japanese). J Jpn Soc Nav Archit Ocean Eng 4(1200):247–255

Acknowledgments

The authors express their earnest gratitude to Professors Y. Kawamura and T. Wada for their valuable suggestions and comments on this work, and thanks are extended to Mr. N. Yamamura, Mr. Y. Yamamuro, Mr. K. Shimoda, and Mr. S. Michiyama for their support. This work was supported by Grant-in-Aid for Scientific Research (A(2) 17206086) from the Ministry of Education, Culture, Sports, Science and Technology of Japan to Yokohama National University. The materials used for the experiments were specially processed and provided by the Nippon Steel Corporation. One of the authors, Md. M.A., is supported by a Japanese Government Scholarship. The authors are most grateful for these supports.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Ahmmad, M.M., Sumi, Y. Strength and deformability of corroded steel plates under quasi-static tensile load. J Mar Sci Technol 15, 1–15 (2010). https://doi.org/10.1007/s00773-009-0066-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00773-009-0066-1