Abstract

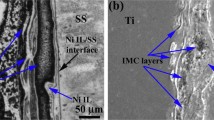

Electromagnetic welding, also referred to as magnetic pulse welding, is a solid-state welding method utilized for joining two distinct materials through high velocity impact. The direct fusion of stainless steel with titanium poses various difficulties owing to the absence of metallurgical compatibility and the occurrence of brittle intermetallic compounds such as FeTi and CrTi. To tackle these challenges, a sustainable, low heat input method like impact welding was applied to address the metallurgical compatibility of the two metals. In this study, a new technique involving aluminum foil, silver foil, and nitinol powder as intermediary materials was investigated to establish a fresh bimetallic structure between Ti-SS304L. Thorough analysis of microstructures, interface formations, and reactions was conducted using scanning electron microscopy and X-ray diffraction. The outcomes showcased successful prevention of intermetallic phase formation through the incorporation of these intermediary materials. Microhardness measurements indicated the absence of brittle FeTi and CrTi phases at the welding interface. Additionally, the weld interface was observed to be situated amid two intermetallic layers at the Ti-SS304L interface, ensuring resistance against corrosion. This inventive method not only averted the creation of harmful intermetallic compounds but also bolstered the overall strength and corrosion resilience of the joint between titanium and stainless steel. The micro hardness obtained at Ti-SS304L interface is 305 Hv and also improved 20% at interface of interlayer materials.

Similar content being viewed by others

References

Zhang, Y., Di, G.Y., Zhou, J.P., Sun, D.Q., Li, H.M.: Microstructure and mechanical property improvement of dissimilar metal joints for TC4 Ti alloy to 304 stainless steel using TA2/Q235 composite interlayer. Met. Mater. Int. 27, 1224–1235 (2021). https://doi.org/10.1007/s12540-019-00507-9

Pasang, T., Pramana, S.S., Kracum, M., Misiolek, W.Z., Aziziderouei, M., Mizutani, M., et al.: Characterisation of intermetallic phases in fusion welded commercially pure titanium and stainless steel 304. Metals (Basel) (2018). https://doi.org/10.3390/met8110863

Kamachi Mudali, U., Ananda Rao, B.M., Shanmugam, K., Natarajan, R., Raj, B.: Corrosion and microstructural aspects of dissimilar joints of titanium and type 304L stainless steel. J. Nucl. Mater. 321, 40–48 (2003). https://doi.org/10.1016/S0022-3115(03)00194-6

Wu, T., Yang, C.: Interfacial evolution and mechanical behavior of explosively welded titanium/steel joint under subsequent heat treatment process. Int. J. Adv. Manuf. Technol. 121, 6303–6314 (2022). https://doi.org/10.1007/s00170-022-09739-3

Roshith, P.: Enhancement of metallurgical and mechanical properties of the materials by performing CO2 laser beam welding. Weld. Int. 35, 59–80 (2021). https://doi.org/10.1080/09507116.2021.1959272

Li, W., Yan, L., Karnati, S., Liou, F., Newkirk, J., Taminger, K.M.B., et al.: Ti–Fe intermetallics analysis and control in joining titanium alloy and stainless steel by laser metal deposition. J. Mater. Process. Technol. 242, 39–48 (2017). https://doi.org/10.1016/j.jmatprotec.2016.11.010

Sarvari, M., Abdollah-zadeh, A., Naffakh-Moosavy, H., Rahimi, A., Parsaeyan, H.: Investigation of collision surfaces and weld interface in magnetic pulse welding of dissimilar Al/Cu sheets. J. Manuf. Process. 45, 356–367 (2019). https://doi.org/10.1016/j.jmapro.2019.07.012

Liu, B., Yang, Q., Wang, Y.: Intereaction and intermetallic phase formation between aluminum and stainless steel. Results Phys 12, 514–524 (2019). https://doi.org/10.1016/j.rinp.2018.11.076

Raoelison, R.N., Racine, D., Zhang, Z., Buiron, N., Marceau, D., Rachik, M.: Magnetic pulse welding: Interface of Al/Cu joint and investigation of intermetallic formation effect on the weld features. J. Manuf. Process. 16, 427–434 (2014). https://doi.org/10.1016/j.jmapro.2014.05.002

Ben-Artzy, A., Stern, A., Frage, N., Shribman, V.: Interface phenomena in aluminium-magnesium magnetic pulse welding. Sci. Technol. Weld. Join. 13, 402–408 (2008). https://doi.org/10.1179/174329308X300136

Cheepu, M., Che, W.S.: Friction Welding of Titanium to Stainless Steel Using Al Interlayer. Trans. Indian Inst. Met. 72, 1563–1568 (2019). https://doi.org/10.1007/s12666-019-01655-7

Li, J.S., Raoelison, R.N., Sapanathan, T., Hou, Y.L., Rachik, M.: Interface evolution during magnetic pulse welding under extremely high strain rate collision: mechanisms, thermomechanical kinetics and consequences. Acta Mater. 195, 404–415 (2020). https://doi.org/10.1016/j.actamat.2020.05.028

Kapil, A., Sharma, A.: Magnetic pulse welding: An efficient and environmentally friendly multi-material joining technique. J. Clean. Prod. 100, 35–58 (2015). https://doi.org/10.1016/j.jclepro.2015.03.042

Wang, H., Wang, Y.: High-velocity impact welding process: a review. Metals (Basel) (2019). https://doi.org/10.3390/met9020144

Kang, B.-Y.: Review of magnetic pulse welding. J Weld Join 33, 7–13 (2015). https://doi.org/10.5781/jwj.2015.33.1.7

Shanthala, K., Sreenivasa, T.N.: Review on electromagnetic welding of dissimilar materials. Front. Mech. Eng. 11, 363–373 (2016). https://doi.org/10.1007/s11465-016-0375-0

Mo, D.F., Song, T.F., Fang, Y.J., Jiang, X.S., Luo, C.Q., Simpson, M.D., et al.: A review on diffusion bonding between titanium alloys and stainless steels. Adv. Mater. Sci. Eng. (2018). https://doi.org/10.1155/2018/8701890

Kahraman, N., Gülenç, B., Findik, F.: Joining of titanium/stainless steel by explosive welding and effect on interface. J. Mater. Process. Technol. 169, 127–133 (2005). https://doi.org/10.1016/j.jmatprotec.2005.06.045

Ghosal, A.M., Chandra, K., Kain, V.: Electrochemical corrosion behavior of explosively welded Ti/Type 304L stainless steel in nitric acid. Corrosion 78, 726–739 (2022). https://doi.org/10.5006/4058

Kundu, S., Chatterjee, S., Olson, D., Mishra, B.: Interface microstructure and strength properties of the diffusion-bonded joints of titanium Cu interlayer stainless steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 39, 2106–2114 (2008). https://doi.org/10.1007/s11661-008-9562-x

Chu, Q., Tong, X., Xu, S., Zhang, M., Li, J., Yan, F.X., et al.: Interfacial investigation of explosion-welded titanium/steel bimetallic plates. J. Mater. Eng. Perform. 29, 78–86 (2020). https://doi.org/10.1007/s11665-019-04535-9

Acknowledgements

The authors gratefully acknowledge the financial support provided for this study by the Board of Research in Nuclear Studies, Dept. of Atomic Energy, India.

Funding

Board of Research in Nuclear Sciences, Dept. of Atomic Energy, India.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chebolu, R., Kakarla, M., Nallu, R. et al. Effect of interlayer materials on microstructure, hardness and corrosion resistance of an electromagnetic welded titanium–stainless steel interface. Acta Mech (2024). https://doi.org/10.1007/s00707-024-03908-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00707-024-03908-z