Abstract

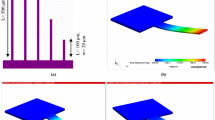

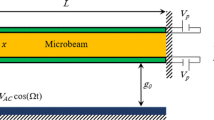

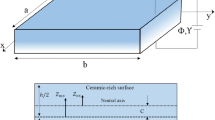

The development of reliable miniaturized devices capable of performing sensing, actuation, and computing functions in a robust manner strongly depends on the mechanical performance of arrays of micromachines subjected to alternating stresses during operation. Consequently, to enhance the functionality and longevity of these micromachines, it is essential to accurately determine the structural behavior under both static and dynamic loadings. However, this requires knowledge of the stress distribution and variation due to texture anisotropy effects in critical micromachine regions and insight into the material behavior at micrometer length scales. Accordingly, the objective of this study was to develop an effective computational mechanics framework for performing stress analysis of micromachines at resonance. Dynamic finite element analysis of resonating micromachines was performed to elucidate the effect of material damping on the dynamic response. A Poisson–Voronoi diagram was incorporated in the critical region of finite element models of polysilicon micromachines to mimic the local inhomogeneity and anisotropy of the polycrystalline microstructure. A computationally effective static finite element analysis of the steady-state resonant response, validated by the results of the dynamic analysis, was used to obtain the steady-state stress distribution in the critical region of polysilicon micromachines with different textures. Moreover, a probabilistic stress analysis of hundreds of simulations was carried out to examine the stochastic nature of the grain geometry, size, and orientation and the beam width on the maximum equivalent von Mises stress in the critical micromachine region. The present study provides an efficient computational methodology, which integrates local texture into continuum mechanics modeling, for performing stress analysis of dynamic microdevices exhibiting different polycrystalline microstructures.

Similar content being viewed by others

References

Basu, A.K., Basu, A., Ghosh, S., Bhattacharya, S.: MEMS Applications in Electronics and Engineering. AIP Publishing, Melville, NY (2023)

Yeatman, E.M.: Applications of MEMS in power sources and circuits. J. Micromech. Microeng. 17, S184 (2007)

Haque, M.A., Saif, M.T.A.: A review of MEMS-based microscale and nanoscale tensile and bending testing. Exp. Mech. 43, 248–255 (2003)

Kahn, H.: Mechanical properties of micromachined structures. In: Bhushan, B. (ed.) Handbook of Nanotechnology, pp. 1685–1702. Springer, Berlin, Germany (2007)

Sharma, N., Hooda, M., Sharma, S.K.: Synthesis and characterization of LPCVD polysilicon and silicon nitride thin films for MEMS applications. J. Mater. 2014, 954618 (2014)

Ericson, F., Greek, S., Söderkvist, J., Schweitz, J.-Å.: High-sensitivity surface micromachined structures for internal stress and stress gradient evaluation. J. Micromech. Microeng. 7, 30 (1997)

Gaj, A., Le Joncour, L., Baczmański, A., Wroński, S., Panicaud, B., Francois, M., Braham, C., Paradowska, A.: Localization of stresses in polycrystalline grains measured by neutron diffraction and predicted by self-consistent model. Mater. Sci. Forum 681, 103–108 (2011)

Benítez, M.A., Fonseca, L., Esteve, J., Benrakkad, M.S., Morante, J.R., Samitier, J., Schweitz, J.A.: Stress-profile characterization and test-structure analysis of single and double ion-implanted LPCVD polycrystalline silicon. Sens. Actuators A 54, 718–723 (1996)

Karner, S., Blank, O., Rösch, M., Burghammer, M., Zalesak, J., Keckes, J., Todt, J.: X-ray nanodiffraction analysis of residual stresses in polysilicon electrodes of vertical power transistors. Materialia 24, 101484 (2022)

Hirsekorn, S.: Elastic properties of polycrystals—a review. Text. Microstruct. 12, 1–14 (1990)

Jensen, B.D., de Boer, M.P., Masters, N.D., Bitsie, F., LaVan, D.A.: Interferometry of actuated microcantilevers to determine material properties and test structure nonidealities in MEMS. J. Microelectromech. Syst. 10, 336–346 (2001)

Corigliano, A., De Masi, B., Frangi, A., Comi, C., Villa, A., Marchi, M.: Mechanical characterization of polysilicon through on-chip tensile tests. J. Microlectromech. Syst. 13, 200–219 (2004)

Jayaraman, S., Edwards, R.L., Hemker, K.J.: Relating mechanical testing and microstructural features of polysilicon thin films. J. Mater. Res. 14, 688–697 (1999)

Ghisi, A., Mariani, S.: Effect of imperfections due to material heterogeneity on the offset of polysilicon MEMS structures. Sensors 19, 3256 (2019)

Sharpe, W.N., Jr., Jackson, K., Coles, G., LeVan, D.A.: Young’s modulus and fracture strength of three polysilicons. Mater. Res. Soc. Symp. Proc. 657, EE5.5 (2001)

DelRio, F.W., Cook, R.F., Boyce, B.L.: Fracture strength of micro- and nano-scale silicon components. Appl. Phys. Rev. 2, 021303 (2015)

Vayrette, R., Galceran, M., Coulombier, M., Godet, S., Raskin, J.P., Pardoen, T.: Size dependent fracture strength and cracking mechanisms in freestanding polycrystalline silicon films with nanoscale thickness. Eng. Fract. Mech. 168, 190–203 (2016)

Mirzazadeh, R., Aldo Ghisi, A., Mariani, S.: Statistical investigation of the mechanical and geometrical properties of polysilicon films through on-chip tests. Micromachines 9, 53 (2018)

McKinstry, H.A., Shull, H.E., Buessem, W.R.: Localized stress in elastic polycrystalline materials. Nucl. Metall. 20, 695–705 (1976)

McKinstry, H.A., Shull, H.E., Buessem, W.R.: Stress and strain fields in idealized polycrystalline materials and the prediction of fracture initiation sites. Nucl. Metall. 20, 929–941 (1976)

Tvergaard, V., Hutchinson, J.W.: Microcracking in ceramics induced by thermal expansion or elastic anisotropy. J. Am. Ceram. Soc. 71, 157–166 (1988)

Kumar, S., Kurtz, S.K.: Simulation of material microstructure using a 3D Voronoi tesselation: calculation of effective thermal expansion coefficient of polycrystalline materials. Acta Metall. Mater. 42, 3917–3927 (1994)

Kumar, S., Kurtz, S.K., Agarwala, V.K.: Micro-stress distribution within polycrystalline aggregate. Acta Mech. 114, 203–216 (1996)

Mullen, R.L., Ballarini, R., Yin, Y., Heuer, A.H.: Monte Carlo simulation of effective elastic constants of polycrystalline thin films. Acta Mater. 45, 2247–2255 (1997)

Ballarini, R., Mullen, R.L., Heuer, A.H.: The effects of heterogeneity and anisotropy on the size effect in cracked polycrystalline films. Int. J. Fract. 95, 19–39 (1999)

Li, X.-D.: K variations and anisotropy: microstructure effect and numerical predictions. ASME J. Eng. Mater. Technol. 125, 65–74 (2003)

Lazar, E.A., Mason, J.K., MacPherson, R.D., Srolovitz, D.J.: Complete topology of cells, grains, and bubbles in three dimensional microstructures. Phys. Rev. Lett. 109, 095505 (2012)

Vittorietti, M., Kok, P.J.J., Sietsma, J., Jongbloed, G.: Accurate representation of the distributions of the 3D Poisson-Voronoi typical cell geometrical features. Comput. Mater. Sci. 166, 111–118 (2019)

Ghazvinian, E., Diederichs, M.S., Quey, R.: 3D random Voronoi grain-based models for simulation of brittle rock damage and fabric-guided micro-fracturing. J. Rock Mech. Geotech. Eng. 6, 506–521 (2014)

Wang, Y., Ballarini, R., Rodin, G.J.: Crack-tip parameters in polycrystalline plates with soft grain boundaries. J. Eng. Mech. 134, 100–109 (2008)

Bourne, D.P., Kok, P.J.J., Roper, S.M., Spanjer, W.D.T.: Laguerre tessellations and polycrystalline microstructures: a fast algorithm for generating grains of given volumes. Philos. Mag. 100, 2677–2707 (2020)

Reischig, P., Ludwig, W.: Three-dimensional reconstruction of intragranular strain and orientation in polycrystals by near-field X-ray diffraction. Curr. Opin. Solid State Mater. Sci. 24, 100851 (2020)

Quey, R., Renversade, L.: Optimal polyhedral description of 3D polycrystals: method and application to statistical and synchrotron X-ray diffraction data. Comput. Methods Appl. Mech. Eng. 330, 308–333 (2018)

Heller, L., Shayanfard, P., Quey, R., Sittner, P., Karafiatova, I., Pawlas, Z.: Elastic grain interactions in a polycrystalline wire analyzed by a numerical model reconstructed from 3D-XRD data. In: 4th International Congress on 3D Materials Science, Elsimore, Denmark (2018)

White, C.D., Xu, R., Sun, X., Komvopoulos, K.: Dynamic MEMS devices for multi-axial fatigue and elastic modulus measurement. Proc. SPIE 4980, 63–74 (2003)

White, C., Xu, R., Sun, X., Komvopoulos, K.: Characterization of microscale material behavior with MEMS resonators. Proc. Nanotechnol. Conf. 1, 494–497 (2003)

Greek, S., Johansson, S.A.I.: Tensile testing of thin film microstructures. Proc. SPIE 3224, 344–351 (1997)

Sharpe, W.N., Turner, K.T., Jr., Edwards, R.L.: Tensile testing of polysilicon. Exp. Mech. 39, 162–170 (1999)

Krulevitch, P., Nguyen, T.D., Johnson, G.C., Howe, R.T., Wenk, H.R., Gronsky, R.: LPCVD polycrystalline silicon thin films: the evolution of structure, texture and stress. Mater. Res. Soc. Proc. 202, 167–172 (1990)

Krulevitch, P.A.: Micromechanical investigations of silicon and Ni–Ti–Cu thin films. Ph.D. thesis, Department of Mechanical Engineering, University of California, Berkeley, CA (1994)

Hibbitt, Karlsson, and Sorensen: ABAQUS/Standard: User's Manual, 5.8 version, Pawtucket, RI (1998)

Madou, M.J.: Fundamentals of Microfabrication: The Science of Miniaturization, 2nd edn. CRC Press, Boca Raton, FL (2002)

Nagasima, N., Kubota, N.: Structures of Si films chemically vapor-deposited on amorphous SiO2 substrates. Jpn. J. Appl. Phys. 14, 1105–1112 (1975)

Kamins, T.I.: Structure and properties of LPCVD silicon films. J. Electrochem. Soc. 127, 686–690 (1980)

Kahn, H., He, A.Q., Heuer, A.H.: Homogeneous nucleation during crystallization of amorphous silicon produced by low-pressure chemical vapour deposition. Philos. Mag. A 82, 137–165 (2002)

Maier-Schneider, D., Köprülülü, A., Holm, S., Obermeier, E.: Elastic properties and microstructure of LPCVD polysilicon films. J. Micromech. Microeng. 6, 436–446 (1996)

Okabe, A., Boots, B., Sugihara, K., Chiu, S.N.: Spatial Tessellations: Concepts and Applications of Voronoi Diagrams, 2nd edn. Wiley, Chichester, England (2000)

DiCenzo, S.B., Wertheim, G.K.: Monte Carlo calculation of the size distribution of supported clusters. Phys. Rev. B 39, 6792–6796 (1989)

Tipper, J.C.: A straightforward iterative algorithm for the planar Voronoi diagram. Inf. Process. Lett. 34, 155–160 (1990)

Tipper, J.C.: FORTRAN programs to construct the planar Voronoi diagram. Comput. Geosci. 17, 597–632 (1991)

Pampuch, R.: Constitution and Properties of Ceramic Materials. Elsevier, New York, NY (1990)

Ting, T.C.T.: Invariants of anisotropic elastic constants. Q. J. Mech. Appl. Math. 40, 431–448 (1987)

Tang, W.C., Tu-Cuong, H., Nguyen, H., Howe, R.T.: Laterally driven polysilicon resonant microstructures. Sens. Actuators 20, 25–32 (1989)

Candler, R.N., Park, W.-T., Hopcroft, M., Kim, B., Kenny, T.W.: Hydrogen diffusion and pressure control of encapsulated MEMS resonators. In: 13th International Conference on Solid-State Sensors, Actuators and Microsystems. Digest of Technical Papers. TRANSDUCERS '05 1, 920–923 (2005)

Buser, R.A., De Rooij, N.F.: Very high Q-factor resonators in monocrystalline silicon. Sens. Actuators A 21–23, 323–327 (1990)

Muhlstein, C.L., Brown, S.B., Ritchie, R.O.: High-cycle fatigue and durability of polycrystalline silicon thin films in ambient air. Sens. Actuators A 94, 177–188 (2001)

Muhlstein, C.L., Stach, E.A., Ritchie, R.O.: Mechanism of fatigue in micron-scale films of polycrystalline silicon for microelectromechanical systems. Appl. Phys. Lett. 80, 1532–1534 (2002)

Massey, F.J., Jr.: The Kolmogorov–Smirnov test for goodness of fit. J. Am. Stat. Assoc. 46, 68–78 (1951)

Acknowledgements

This work was funded by the National Science Foundation (NSF) under Grant No. DMI-9872324 and the Defense Advanced Research Projects Agency (DARPA) under Grant No. DABT63-98-1-0011.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, R., Komvopoulos, K. A Poisson–Voronoi-based finite element stress analysis of resonating polysilicon micromachines. Acta Mech 234, 6705–6721 (2023). https://doi.org/10.1007/s00707-023-03775-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-023-03775-0