Abstract

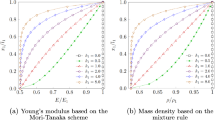

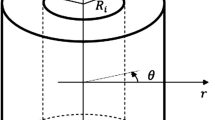

Interference fit is a classic issue in mechanical engineering. In this paper, under the axial/spherical symmetrical assumption, the analytical solutions for the interference fit problem of the internal and external functionally graded materials (FGMs) hollow cylinder/spherical shell are obtained. Herein, the unified form of the FGMs hollow cylinder/spherical shell basic equation is given by introducing a geometric parameter. The degradations of the analytical solutions in this paper are consistent with the corresponding results in the existing work. The effects of interference value, structural material parameters, and geometric dimensions on the displacement and stress distribution of FGMs structures are analyzed numerically.

Similar content being viewed by others

References

Koizumi, M.: FGM activities in Japan. Compos. B Eng. 28, 1–4 (1997)

Jha, D.K., Kant, T., Singh, R.K.: A critical review of recent research on functionally graded plates. Compos. Struct. 96, 833–849 (2013)

Dai, H.L., Rao, Y.N., Dai, T.: A review of recent researches on FGM cylindrical structures under coupled physical interactions, 2000–2015. Compos. Struct. 152, 199–225 (2016)

Devesh, P., Tarun, K.: A critical review of stress and vibration analyses of functionally graded shell structures. Compos. Struct. 210, 787–809 (2019)

Garg, A., Belarbi, M.O., Chalak, H.D., et al.: A review of the analysis of sandwich FGM structures. Compos. Struct. 258, 113427 (2020)

Ghassan, F.S., Mostafa, O.B., Kheng, L.G.: Review of thermoelastic, thermal properties and creep analysis of functionally graded cylindrical shell. Aust. J. Mech. Eng. (2022). https://doi.org/10.1080/14484846.2022.2100045

Horgan, C.O., Chan, A.M.: The pressurized hollow cylinder or disk problem for functionally graded isotropic linearly elastic materials. J. Elast. 55, 43–59 (1999)

Tutuncu, N., Ozturk, M.: Exact solutions for stresses in functionally graded pressure vessels. Compos. B 32, 483–486 (2001)

Shi, P.P., Xie, J.: Revisiting classic problems of exact solutions for stresses in functionally graded pressure vessels. Mech. Res. Commun. 20, 103609 (2020)

Xie, J., Hao, S., Wang, W.S., et al.: Analytical solution of stress in functionally graded cylindrical/spherical pressure vessel. Arch. Appl. Mechanics 66, 3341–3363 (2021)

Sarathchandra, D.T., Kanmani, S.S., Venkaiah, N.: Modeling and analysis of functionally graded cylindrical shell. Mater. Today 5, 8587–8595 (2018)

Tutuncu, N., Temel, B.: A novel approach to stress analysis of pressurized FGM cylinders, disks and spheres. Compos. Struct. 91, 385–390 (2009)

Chirag, S., Srikant, S.P.: Functionally graded cylinders: asymptotically exact analytical formulations. Appl. Math. Model. 54, 782–802 (2018)

Ghannad, M., Rahimi, G.H., Zamani, N.M.: Elastic analysis of pressurized thick cylindrical shells with variable thickness made of functionally graded materials. Compos. B Eng. 45, 388–396 (2013)

Yang, Y.Y.: Time-dependent stress analysis in functionally graded materials. Int. J. Solids Struct. 37, 7593–7608 (2000)

Nejad, M.Z., Fatehi, P.: Exact elasto-plastic analysis of rotating thick-walled cylindrical pressure vessels made of functionally graded materials. Int. J. Eng. Sci. 86, 26–43 (2015)

Tutuncu, N.: Stresses in thick-walled FGM cylinders with exponentially-varying properties. Eng. Struct. 29(09), 2032–2035 (2007)

Chen, Y.Z., Lin, X.Y.: Elastic analysis for thick cylinders and spherical pressure vessels made of functionally graded materials. Comput. Mater. Sci. 44(2), 581–587 (2008)

Nejad, M.Z., Abedi, M., Lotfian, M.H., et al.: Exact and numerical elastic analysis for the FGM thick-walled cylindrical pressure vessels with exponentially-varying properties. Arch. Metall. Mater. 61(3), 1649–1654 (2016)

Sburlati, R.: Analytical elastic solutions for pressurized hollow cylinders with internal functionally graded coatings. Compos. Struct. 94, 3592–3600 (2012)

Shi, P.P., Xie, J.: Exact solution of magneto-elastoplastic problem of functionally graded cylinder subjected to internal pressure. Appl. Math. Model. 123, 835–855 (2023)

Xie, J., Shi, P.P., Li, F.J.: Exact solutions for the symmetric elastoplastic response of functionally graded pressure vessels. Thin-Walled Struct. 192, 111165 (2023)

Li, X.F., Peng, X.L.: A Pressurized functionally graded hollow cylinder with arbitrarily varying material properties. J. Elast. 96(1), 81–95 (2009)

Peng, X.L., Li, X.F.: Transient response of temperature and thermal stresses in a functionally graded hollow cylinder. J. Therm. Stress. 33(4), 1–16 (2010)

Dryden, J., Jayaraman, K.: Effect of inhomogeneity on the stress in pipes. J. Elast. 83, 179–189 (2006)

Shi, P.P., Xie, J., Li, X.: Multilayer heterostructure inhomogeneous model for pressurized functionally graded annular structures (cylinder/sphere/annulus) with arbitrary elastic property along the radial direction. Compos. Struct. 322, 117425 (2023)

Sburlati, R.: Analytical elastic solutions for pressurized hollow cylinders with internal functionally graded coatings. Compos. Struct. 94(12), 3592–3600 (2012)

Liu, T.J., Wang, Y.S.: Axisymmetric frictionless contact problem of a functionally graded coating with exponentially varying modulus. Acta Mech. 199(1–4), 151–165 (2008)

Naghibi, S.R., Wang, W., Ghavi, M.R., et al.: Several defects in a hollow cylinder coated by a functionally graded material (FGM) subjected to torsional loading. Iran. J. Sci. Technol. Trans. Mech. Eng. 47(1), 109–131 (2019)

Abeidi, A., Dag, S.: Computational elastodynamics of functionally graded thick-walled cylinders and annular coatings subjected to pressure shocks. Int. J. Press. Vessels Pip. 200, 104824 (2022)

Li, P.X., Liu, T.J.: The adhesive contact problem between a graded coated half-space and a cylindrical indenter by using a Maugis model. J. Adhes. Sci. Technol. 32(22), 2494–2508 (2018)

Fu, P.L., Zhao, J.Z., Zhang, X., et al.: Elastic shakedown analysis of two-dimensional thermo-elastic rolling/sliding contact for a functionally graded coating/substrate structure with arbitrarily varying thermo-elastic properties. Compos. Struct. 280, 114894 (2022)

Liu, T.J., Zhang, C.Z., Wang, Y.S., et al.: The axisymmetric stress analysis of double contact problem for functionally graded materials layer with arbitrary graded materials properties. Int. J. Solids Struct. 96, 229–239 (2016)

Lanciotti, A., Polese, C.: The effect of interference-fit fasteners on the fatigue life of central hole specimens. Fatigue Fract. Eng. Mater. Struct. 28, 587–597 (2005)

Chakherlou, T., Mirzajanzadeh, M., Vogwell, J.: Experimental and numerical investigations into the effect of an interference fit on the fatigue life of double shear lap joints. Eng. Fail. Anal. 16, 2066–2080 (2009)

Chakherlou, T., Mirzajanzadeh, M., Abazadeh, B., et al.: An investigation about interference fit effect on improving fatigue life of a holed single plate in joints. Eur. J. Mech. A Solids 29, 675–682 (2010)

Mukherjee, S., Mandal, A.K.: Static and dynamic characteristics of a compound sphere using initial stress reference independence. Int. J. Non-Linear Mech. 136, 103787 (2021)

Jiang, J.F., Bi, Y.B.: An elastic–plastic analysis of interference fit connection. IOP Conf. Ser.: Mater. Sci. Eng. 504, 012071 (2019)

Qiu, J., Zhou, M.: Analytical solution for interference fit for multi-layer thick-walled cylinders and the application in crankshaft bearing design. Appl. Sci. 6(6), 167 (2016)

Hu, J., Mi, S., Yang, Z., et al.: An experimental investigation on bearing behavior and failure mechanism of bolted composite interference-fit joints under thermal effects. Eng. Fail. Anal. 131, 105830 (2022)

Ding, Y.X., Li, Y., Zhang, K.F., et al.: Analysis of bolt-to-laminate interface friction in bolted composite joint with interference-fit. Mater. Res. Innov. 19(6), 42–45 (2015)

Hava, H., Omer, M., Asuman, K., et al.: Analysis of elastic–plastic interference-fit joints. Procedia Eng. 81, 2030–2035 (2014)

Xu, Z., Hao, J., Tong, L., et al.: Theoretical and experimental investigation on interference fit in electromagnetic riveting. Int. J. Mech. Sci. 156, 261–271 (2019)

Madej, J., Śliwka, M.: Analysis of interference-fit joints. Appl. Sci. 11(23), 11428 (2021)

Jun, Y., Yang, Z., Chen, C., et al.: Stress intensity factors for thick-walled cylinder under interference fit. In: International Conference on System Reliability and Safety, pp. 359–363 (2019)

Wang, X., Lou, Z., Wang, X., et al.: Prediction of stress distribution in press-fit process of interference fit with a new theoretical model. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 233(8), 2834–2846 (2019)

Kim, S., Kim, D.: Interference-fit effect on improving bearing strength and fatigue life in a pin-loaded woven carbon fiber-reinforced plastic laminate. J. Eng. Mater. Technol. 141(2), 021006 (2019)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 11802225, 12061055) the Key projects of Ningxia Natural Science Foundation (No. 2022AAC02005) and the Ningxia high level scientific and technological innovation leading talent project (2021GKLRLX06).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to effect the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xie, J., Li, H., Shi, P. et al. Analytical solution for the interference fit problem of functionally graded materials hollow cylinder/spherical shell. Acta Mech 235, 133–145 (2024). https://doi.org/10.1007/s00707-023-03740-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-023-03740-x