Abstract

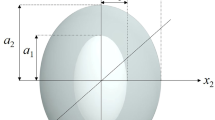

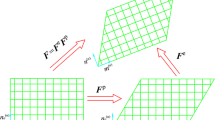

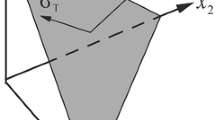

Porous nanocrystalline NiTi shape memory alloy (SMA) benefit from a combination of the smart responses of nanograined SMA and the characteristics of porous materials, showing great potential in the high-tech field. Porosity and grain size exert an influence on the microstructure evolution during phase transformations, thus possessing the ability to alter the transformation characteristics of NiTi SMA. To investigate the porosity and grain size-dependent superelastic behaviors of porous nanocrystalline NiTi, the constitutive model incorporating grain size effects and tensile–compressive asymmetry for dense nanocrystalline NiTi is first developed. Based on the dense SMA model, porous nanocrystalline NiTi SMA is regarded as a composite material consisting of the void phase and the SMA matrix phase. The voids are treated as inclusions embedded in the SMA matrix composed of grain core and grain boundary. Tensile–compressive asymmetry, transformation hardening modulus associated with intrinsic length scale and grain size are incorporated into the modified Gurson–Tvergaard–Needleman potential function, leading to the construction of constitutive model for porous nanocrystalline NiTi SMA. Simulated results demonstrate that the proposed model is capable to describe the characteristics of porous nanocrystalline NiTi SMA, such as grain size and porosity dependent superelasticity and tensile–compressive asymmetry. Using the developed model, the combined effects of porosity and grain size on the critical transformation stresses, strain hardening, peak stresses, tensile–compressive asymmetry behaviors and the superelastic stress–strain hysteresis loop are analyzed.

Similar content being viewed by others

References

Neeraj, S., Abhishek, S., Kapil, K.G., Shaman, G., Shashi, B., Gaurav, K.S.: Transformation temperature and corrosion behavior of porous NiTi and NiTiCu shape memory alloy. Mater. Today Proc. 63, 215–218 (2022). https://doi.org/10.1016/j.matpr.2022.02.519

Chen, X., Wu, Z., Tang, X., Hu, H., Lu, S., Zheng, H.: Orientation-dependent shock compression behavior of non-porous/porous NiTi shape memory alloy: an atomic scale study. Mater. Today Commun. 30, 103114 (2022). https://doi.org/10.1016/j.mtcomm.2021.103114

Xu, J., Bao, L., Liu, A., Jin, X., Tong, Y., Luo, J., Zhong, Z., Zheng, Y.: Microstructure, mechanical properties and superelasticity of biomedical porous NiTi alloy prepared by microwave sintering. Mater. Sci. Eng. C 46, 387–393 (2015). https://doi.org/10.1016/j.msec.2014.10.053

Zhao, M., Qing, H., Wang, Y., Liang, J., Zhao, M., Geng, Y., Liang, J., Lu, B.: Superelastic behaviors of additively manufactured porous NiTi shape memory alloys designed with Menger sponge-like fractal structures. Mater. Des. 200, 109448 (2021). https://doi.org/10.1016/j.matdes.2021.109448

Akbarinia, S., Sadrnezhaad, S.K., Hosseini, S.A.: Porous shape memory dental implant by reactive sintering of TiH2–Ni-Urea mixture. Mater. Sci. Eng. C 107, 110213 (2020). https://doi.org/10.1016/j.msec.2019.110213

Khalatbari, M., Daneshpour, M.: Synthesis of porous nanostructure NiTi implant and measurement of thermomechanical properties. Nanomed. Res. J. 2(4), 267–272 (2017). https://doi.org/10.22034/nmrj.2017.04.008

Zhu, J., Gao, Y., Wang, D., Zhang, T., Wang, Y.: Taming martensitic transformation via concentration modulation at nanoscale. Acta Mater. 130, 196–207 (2017). https://doi.org/10.1016/j.actamat.2017.03.042

Zhu, J., Zhang, G., Huang, H., Wang, D., Chen, P., Yang, X.: A novel two-stage martensitic transformation induced by nanoscale concentration modulation in a TiNb-based shape memory alloy. Comput. Mater. Sci. 200, 110843 (2021). https://doi.org/10.1016/j.commatsci.2021.110843

Ahadi, A., Sun, Q.: Stress-induced nanoscale phase transition in superelastic NiTi by in situ X-ray diffraction. Acta Mater. 90, 272–281 (2015). https://doi.org/10.1016/j.actamat.2015.02.024

Kabirifar, P., Chu, K., Ren, F., Sun, Q.: Effects of grain size on compressive behavior of NiTi polycrystalline superelastic macro- and micropillars. Mater. Lett. 214, 53–55 (2018). https://doi.org/10.1016/j.matlet.2017.11.069

Huang, K., Yin, H., Li, M., Sun, Q.: Grain size dependence of stress-assisted two-way memory effect in Ti-50.04 at.% Ni shape memory alloy. Mater. Sci. Eng. A 856, 143872 (2022). https://doi.org/10.1016/j.msea.2022.143872

Gur, S., Frantziskonis, G.N., Muralidharan, K.: Atomistic simulation of shape memory effect (SME) and superelasticity (SE) in nano-porous NiTi shape memory alloy (SMA). Comput. Mater. Sci. 152, 28–37 (2018). https://doi.org/10.1016/j.commatsci.2018.05.031

Liu, B., Li, Z., Li, W., Pan, Y., Wu, W.: Molecular dynamics simulation of the porosity effect on transformation mechanism of nanocrystalline porous NiTi shape memory alloy. Mater. Today Commun. 34, 105320 (2023). https://doi.org/10.1016/j.mtcomm.2023.105320

Xi, S., Su, Y.: A phase field study of the grain-size effect on the thermomechanical behavior of polycrystalline NiTi thin films. Acta Mech. 232, 4545–4566 (2021). https://doi.org/10.1007/s00707-021-03074-6

Yin, H., He, Y., Moumni, Z., Sun, Q.: Effects of grain size on tensile fatigue life of nanostructured NiTi shape memory alloy. Int. J. Fatigue 88, 166–177 (2016). https://doi.org/10.1016/j.ijfatigue.2016.03.023

Xu, B., Yu, C., Kan, Q., Kang, G.: Phase field study on the microscopic mechanism of the cyclic degradation of shape memory effect in nano-polycrystalline NiTi shape memory alloys. Eur. J. Mech. A Solids 93, 104544 (2022). https://doi.org/10.1016/j.euromechsol.2022.104544

Xia, M., Liu, P., Sun, Q.: Grain size dependence of Young’s modulus and hardness for nanocrystalline NiTi shape memory alloy. Mater. Lett. 211, 352–355 (2018). https://doi.org/10.1016/j.matlet.2017.10.024

Chen, J., Yin, H., Sun, Q.: Effects of grain size on fatigue crack growth behaviors of nanocrystalline superelastic NiTi shape memory alloys. Acta Mater. 195, 141–150 (2020). https://doi.org/10.1016/j.actamat.2020.05.008

Xu, B., Kang, G., Yu, C., Kan, Q.: Phase field simulation on the grain size dependent superelasticity and shape memory effect of nanocrystalline NiTi shape memory alloys. Int. J. Eng. Sci. 156, 103373 (2020). https://doi.org/10.1016/j.ijengsci.2020.103373

Li, M., Sun, Q.: Nanoscale phase transition behavior of shape memory alloys—closed form solution of 1D effective modelling. J. Mech. Phys. Solids 110, 21–37 (2018). https://doi.org/10.1016/j.jmps.2017.09.008

Li, B., Niu, C., Zhang, T., Chen, G., Zhang, G., Wang, D., Zhou, X., Zhu, J.: Advances of machining techniques for gradient structures in multi-principal-element alloys. Rare Met. 41, 4015–4026 (2022). https://doi.org/10.1007/s12598-022-02075-1

Chen, J., Liu, B., Xing, L., Liu, W., Lei, L., Fang, G.: Toward tunable mechanical behavior and enhanced elastocaloric effect in NiTi alloy by gradient structure. Acta Mater. 226, 117609 (2022). https://doi.org/10.1016/j.actamat.2021.117609

Zhu, J., Wu, H., Wu, Y., Wang, H., Zhang, T., Xiao, H., Wang, Y., Shi, S.: Influence of Ni4Ti3 precipitation on martensitic transformations in NiTi shape memory alloy: R phase transformation. Acta Mater. 207, 116665 (2021). https://doi.org/10.1016/j.actamat.2021.116665

Yu, C., Kang, G., Kan, Q.: An equivalent local constitutive model for grain size dependent deformation of NiTi polycrystalline shape memory alloys. Int. J. Mech. Sci. 138–139, 34–41 (2018). https://doi.org/10.1016/j.ijmecsci.2018.02.001

Yu, C., Kang, G., Kan, Q.: A micromechanical constitutive model for grain size dependent thermo-mechanically coupled inelastic deformation of super-elastic NiTi shape memory alloy. Int. J. Plast. 105, 99–127 (2018). https://doi.org/10.1016/j.ijplas.2018.02.005

Zhu, X., Dui, G.: Constitutive model for nanocrystalline NiTi shape memory alloys considering grain size effects and tensile–compressive asymmetry. J. Appl. Phys. 132, 194304 (2022). https://doi.org/10.1063/5.0119553

Yu, C., Kang, G., Xie, X., Rao, W.: A micromechanical model for the grain size dependent super-elasticity degeneration of NiTi shape memory alloys. Mech. Mater. 125, 35–51 (2018). https://doi.org/10.1016/j.mechmat.2018.07.008

Xia, X., Du, Z., Zhang, J., Li, J., Weng, G.J.: A hierarchical scheme from nano to macro scale for the strength and ductility of graphene/metal nanocomposites. Int. J. Eng. Sci. 162, 103476 (2021). https://doi.org/10.1016/j.ijengsci.2021.103476

Lester, B.T., Baxevanis, T., Chemisky, Y., Lagoudas, D.C.: Review and perspectives: shape memory alloy composite systems. Acta Mech. 226, 3907–3960 (2015). https://doi.org/10.1007/s00707-015-1433-0

Qiao, L., Radovitzky, R.: Computational modeling of size-dependent superelasticity of shape memory alloys. J. Mech. Phys. Solids 93, 93–117 (2016). https://doi.org/10.1016/j.jmps.2016.01.004

Zhu, X., Dui, G., Zheng, Y.: A micromechanics-based constitutive model for nanocrystalline shape memory alloys incorporating grain size effects. J. Intell. Mater. Syst. Struct. 33, 756–768 (2022). https://doi.org/10.1177/1045389X211028294

Zhu, S., Bouby, C., Cherouat, A., Zineb, T.B.: 3D reconstitution and numerical analysis of superelastic behavior of porous shape memory alloy. Int. J. Solids Struct. 168, 109–122 (2019). https://doi.org/10.1016/j.ijsolstr.2019.03.023

Viet, N.V., Zaki, W.: A thermomechanical constitutive model for porous SMAs accounting for the influence of void evolution. Mech. Mater. 155, 103779 (2021). https://doi.org/10.1016/j.mechmat.2021.103779

Entchev, P.B., Lagoudas, D.C.: Modeling porous shape memory alloys using micromechanical averaging techniques. Mech. Mater. 34(1), 1–24 (2002). https://doi.org/10.1016/S0167-6636(01)00088-6

Liu, B., Xie, B., Xue, L.: A constitutive model of porous SMAs considering tensile-compressive asymmetry behaviors. J. Mech. Behav. Biomed. Mater. 32, 185–191 (2014). https://doi.org/10.1016/j.jmbbm.2013.12.027

Nemat-Nasser, S., Su, Y., Guo, W.G., Isaacs, J.: Experimental characterization and micromechanical modeling of superelastic response of a porous NiTi shape-memory alloy. J. Mech. Phys. Solids 53(10), 2320–2346 (2005). https://doi.org/10.1016/j.jmps.2005.03.009

Ashrafi, M.J., Arghavani, J., Naghdabadi, R., Auricchio, F.: A three-dimensional phenomenological constitutive model for porous shape memory alloys including plasticity effects. J. Intell. Mater. Syst. Struct. 27(5), 608–624 (2016). https://doi.org/10.1177/1045389X15575085

Entchev, P.B., Lagoudas, D.C.: Modeling of transformation-induced plasticity and its effect on the behavior of porous shape memory alloys. Part II: porous SMA response. Mech. Mater. 36(9), 893–913 (2004). https://doi.org/10.1016/j.mechmat.2003.08.005

Ashrafi, M.J., Arghavani, J., Naghdabadi, R., Sohrabpour, S., Auricchio, F.: Theoretical and numerical modeling of dense and porous shape memory alloys accounting for coupling effects of plasticity and transformation. Int. J. Solids Struct. 88–89, 248–262 (2016). https://doi.org/10.1016/j.ijsolstr.2016.03.003

Olsen, J.S., Zhang, Z.: Effect of spherical micro-voids in shape memory alloys subjected to uniaxial loading. Int. J. Solids Struct. 49(14), 1947–1960 (2012). https://doi.org/10.1016/j.ijsolstr.2012.03.041

Zhu, X., Dui, G.: Modeling of superelastic-plastic behavior of porous shape memory alloys incorporating void shape effects. Acta Mech. Solida Sin. 34(5), 13 (2021). https://doi.org/10.1007/s10338-021-00214-2

Zhu, X., Chu, L., Dui, G.: Constitutive modeling of porous shape memory alloys using Gurson–Tvergaard–Needleman model under isothermal conditions. Int. J. Appl. Mech. 12(3), 2050038 (2020). https://doi.org/10.1142/S1758825120500386

Bahrami, H., Hoseini, S.H., Voyiadjis, G.Z.: Fracture analysis of shape memory alloys in martensite and austenite phase based on the voids behavior. Mech. Mater. 137, 103119 (2019). https://doi.org/10.1016/j.mechmat.2019.103119

Sun, Q., Ahadi, A., Li, M., Chen, M.: Effects of grain size on phase transition behavior of nanocrystalline shape memory alloys. Sci. China Technol. Sci. 57, 671–679 (2014). https://doi.org/10.1007/s11431-014-5505-5

Cherkaoui, M., Sun, Q., Song, G.: Micromechanics modeling of composite with ductile matrix and shape memory alloy reinforcement. Int. J. Solids Struct. 37, 1577–1594 (2000). https://doi.org/10.1016/S0020-7683(98)00332-1

Mochida, T., Taya, M., Lloyd, D.J.: Fracture of particles in a particle/metal matrix composite under plastic straining and its effect on the Young’s modulus of the composite. Mater. Trans. JIM 32(10), 931–942 (1991). https://doi.org/10.2320/matertrans1989.32.931

Gurson, A.L.: Continuum theory of ductile rupture by void nucleation and growth: Part I—yield criteria and flow rules for porous ductile media. J. Eng. Mater. Technol. 99(1), 2–15 (1977). https://doi.org/10.2172/7351470

Tvergaard, V.: Influence of voids on shear band instabilities under plane strain conditions. Int. J. Fract. 17(4), 389–407 (1981). https://doi.org/10.1007/bf00036191

Lee, J.H., Oung, J.: Yield functions and flow rules for porous pressure-dependent strain-hardening polymeric materials. J. Appl. Mech. 67(2), 288–297 (2000). https://doi.org/10.1115/1.1305278

Ahadi, A., Sun, Q.: Effects of grain size on the rate-dependent thermomechanical responses of nanostructured superelastic NiTi. Acta Mater. 76, 186–197 (2014). https://doi.org/10.1016/j.actamat.2014.05.007

Acknowledgements

The authors acknowledge the financial support of the National Natural Science Foundation of China (NNSFC, Grant No. 11772041).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, X., Lei, Y., Wan, H. et al. Constitutive modeling of porosity and grain size effects on superelasticity of porous nanocrystalline NiTi shape memory alloy. Acta Mech 234, 6499–6513 (2023). https://doi.org/10.1007/s00707-023-03721-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-023-03721-0