Abstract

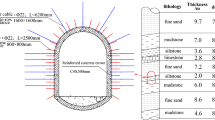

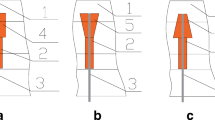

Excavation disturbance of deep chamber can easily cause the broken and deterioration of surrounding rock, bringing hidden danger to construction safety. Based on post-peak strength drop model, considering the influence of grouting seepage force, the analytical solutions of stress and displacement of surrounding rock in deep circular chamber before and after grouting were deduced by using orthogonal non-associated flow rule. Then, the evolution laws of stress and displacement with different chamber depths, radii and grouting thicknesses were analyzed in detail. Finally, the correctness of the theoretical solutions was verified by an engineering field. Results show that grouting has a good modulating control effect on the stress contribution and displacement of the surrounding rock, while on the magnitudes of the stress is not obvious; the influence of chamber depth on the stress and displacement of surrounding rock is significant, while chamber radius and grouting thickness is insignificant.

Similar content being viewed by others

Abbreviations

- p 0 :

-

Hydrostatic stress

- p i :

-

Internal pressure at chamber wall

- r a :

-

Radius of the chamber

- r g :

-

Radius of grouting zone

- r p :

-

Radius of plastic zone

- E :

-

Elastic modulus of surrounding rock

- μ :

-

Poisson’s ratio of surrounding rock

- σ r :

-

Radial stress

- σ θ :

-

Circumferential stress

- ε r :

-

Radial strain

- ε θ :

-

Circumferential strain

- t :

-

Normalized dimensionless length

- r :

-

Radial distance from the center of the chamber

- u :

-

Radial displacement

- Φ :

-

Stress function

- σ 1 :

-

Major principal stress

- σ 3 :

-

Minor principal stress

- ε 1 :

-

Major principal strain

- ε 3 :

-

Minor principal strain

- η :

-

Material constant for Mohr–Coulomb rock mass

- ξ :

-

Material constant for Mohr–Coulomb rock mass

- c :

-

Cohesion of surrounding rock

- φ :

-

Internal friction angle of surrounding rock

- Ψ :

-

Dilation angle

- Θ :

-

Dilation coefficient

- p wat :

-

Pore water pressure

- p w :

-

Grouting pressure

- t g :

-

Normalized dimensionless radius of grouting zone

- t p :

-

Normalized dimensionless radius of plastic zone

- Superscript e:

-

Elastic part of strain

- Superscript p:

-

Plastic part of strain

- Subscript g:

-

Refers to quantities corresponding to the grouting zone

- Subscript e:

-

Refers to quantities corresponding to the elastic zone

- Subscript p:

-

Refers to quantities corresponding to the plastic zone

- Subscript pe:

-

Refers to quantities corresponding at elastic–plastic interface

- Subscript pg:

-

Refers to quantities corresponding at the interface between the grouting zone and the plastic zone

- Subscript r:

-

Values of rock mass parameters after strength drop

References

Brown, E.T., Bray, J.W., Ladanyi, B., et al.: Ground response curves for rock tunnels. J. Geotech. Eng. 109(1), 15–39 (1983). https://doi.org/10.1061/(ASCE)0733-9410(1983)109:1(15)

Reed, M.B.: Stresses and displacements around a cylindrical cavity in soft rock. IMA J. Appl. Math. 36(3), 223–245 (1986). https://doi.org/10.1093/imamat/36.3.223

Ogawa, T., Lo, K.Y.: Effects of dilatancy and yield criteria on displacements around tunnels. Can. Geotech. J. 24(1), 100–113 (1987). https://doi.org/10.1139/t87-009

Wang, Y.: Ground response of circular tunnel in poorly consolidated rock. J. Geotech. Eng. 122(9), 703–708 (1996). https://doi.org/10.1061/(ASCE)0733-9410(1996)122:9(703)

Carranza-Torres, C., Fairhurst, C.: The elasto-plastic response of underground excavations in rock masses that satisfy the Hoek–Brown failure criterion. Int. J. Rock Mech. Min. Sci. 36(6), 777–809 (1999). https://doi.org/10.1016/S0148-9062(99)00047-9

Carranza-Torres, C.: Elasto-plastic solution of tunnel problems using the generalized form of the Hoek–Brown failure criterion. Int. J. Rock Mech. Min. Sci. 41(3), 480–481 (2004). https://doi.org/10.1016/j.ijrmms.2003.12.014

Chen, R., Tonon, F.: Closed-form solutions for a circular tunnel in elastic–brittle–plastic ground with the original and generalized Hoek–Brown failure criteria. Rock Mech. Rock Eng. 44(2), 169–178 (2011). https://doi.org/10.1007/s00603-010-0122-5

Sharan, S.K.: Elastic–brittle–plastic analysis of circular openings in Hoek–Brown media. Int. J. Rock Mech. Min. Sci. 40(6), 817–824 (2003). https://doi.org/10.1016/S1365-1609(03)00040-6

Sharan, S.K.: Exact and approximate solutions for displacements around circular openings in elastic–brittle–plastic Hoek–Brown rock. Int. J. Rock Mech. Min. Sci. 42(4), 542–549 (2005). https://doi.org/10.1016/j.ijrmms.2005.03.019

Sharan, S.K.: Analytical solutions for stresses and displacements around a circular opening in a generalized Hoek–Brown rock. Int. J. Rock Mech. Min. Sci. 45(1), 78–85 (2008). https://doi.org/10.1016/j.ijrmms.2007.03.002

Park, K.H., Kim, Y.J.: Analytical solution for a circular opening in an elastic–brittle–plastic rock. Int. J. Rock Mech. Min. Sci. 43(4), 616–622 (2006). https://doi.org/10.1016/j.ijrmms.2005.11.004

Li, Z.L., Ren, Q.W., Wang, Y.H.: Elasto-plastic analytical solution of deep-buried circle tunnel considering fluid flow field. Chin. J. Rock Mech. Eng. 23(8), 1291–1295 (2004). (in Chinese)

Rong, C.X., Cheng, H.: Stability analysis of rocks around tunnel with ground water permeation. Chin. J. Rock Mech. Eng. 23(5), 741–744 (2004). (in Chinese)

Zareifard, M.R., Fahimifar, A.: Analytical solutions for the stresses and deformations of deep tunnels in an elastic–brittle–plastic rock mass considering the damaged zone. Tunn. Undergr. Space Technol. 58, 186–196 (2016). https://doi.org/10.1016/j.tust.2016.05.007

Liu, C.X., Yang, L.D., Li, P.: Elastic-plastic analytical solution of deep buried circle tunnel considering stress redistribution. Eng. Mech. 26(2), 16–20 (2009). (in Chinese)

Huang, F., Yang, X.L.: Analytical solution of circular openings subjected to seepage in Hoek–Brown media. Rock Soil Mech. 31(5), 1627–1632 (2010). https://doi.org/10.16285/j.rsm.2010.05.013. (in Chinese)

Zhang, Y.J., Zhang, W.Q.: An elastoplastic analytical solution for circular cavern considering combined thermo-hydro-mechanical action. Rock Soil Mech. 34(S2), 41–44 (2013). https://doi.org/10.16285/j.rsm.2013.s2.003. (in Chinese)

Zareifard, M.R., Fahimifar, A.: Elastic–brittle–plastic analysis of circular deep underwater cavities in a Mohr-Coulomb rock mass considering seepage forces. Int. J. Geomech. 15(5), 04014077 (2015). https://doi.org/10.1061/(ASCE)GM.1943-5622.0000400

Wang, H.Y.: Analytical solution for elasto-plastic coupling of the brittle rock. Modern Tunn. Technol. 51(6), 29–34+40 (2014). https://doi.org/10.13807/j.cnki.mtt.2014.06.006. (in Chinese)

Hu, L.S., Wang, J.X., Lu, Y.R.: Elastoplastic solution for deep tunnel considering influences of groundwater, grouting and lining. Rock Soil Mech. 33(3), 757–766 (2012). https://doi.org/10.16285/j.rsm.2012.03.037

Li, X.F.: Unified Analytic Elasto-Plastic Solution of Deep Circular Hydraulic Tunnel with Effects of Liner-Grout-Rock Ground Water. Doctoral thesis, Shanghai Jiao Tong University, Shanghai (2016) (in Chinese)

Zhang, Y., Zhang, D., Fang, Q., et al.: Analytical solutions of non-darcy seepage of grouted subsea tunnels. Tunn. Undergr. Space Technol. 96, 103182 (2020). https://doi.org/10.1016/j.tust.2019

He X.N.: Study on Cooperative Anti-permeability Support Design of Lining Structure and the Reinforced Surrounding Rock of Deep Buried Tunnel with High Water Pressure. Doctoral thesis, University of Science and Technology Beijing, Beijing (2022) (in Chinese)

Zhao, Z., Sun, W., Chen, S., et al.: Displacement of surrounding rock in a deep circular hole considering double moduli and strength-stiffness degradation. Appl. Math. Mech. 41(12), 1847–1860 (2020). https://doi.org/10.1007/s10483-020-2665-9

Yuan, L.J., Li, Z.S., Wu, S.Z., et al.: Engineering Seepage Mechanics and Application. China Building Materials Press, Beijing (2001). (in Chinese)

Ye, F., Guo, H.W., Duan, Z.J., et al.: Disturbance mechanical problems induced by synchronous grouting in deep shield tunnels. Chin. J. Geotech. Eng. 41(5), 855–863 (2019). https://doi.org/10.11779/CJGE201905008. (in Chinese)

Gao, Y.F., Fan, Q.Z., Wang, H.P.: Grouting reinforcement test of rock after peak value of strength and roadway stability controll. Rock Soil Mech. 25(S1), 21–24 (2004). https://doi.org/10.16285/j.rsm.2004.s1.005. (in Chinese)

Wang, H.P., Gao, Y.F., Li, S.C.: Uniaxial experiment study on mechanical properties of reinforced broken rocks pre-and-post grouting. Chin. J. Undergr. Space Eng. 3(1), 27–31+39 (2007). (in Chinese)

Zong, Y.J., Han, L.J., Han, G.L.: Mechanical characteristics of confined grouting reinforcement for cracked rock mass. J. Min. Saf. Eng. 30(4), 483–488 (2013). (in Chinese)

Huang, Y., Yang, W., Zhao, A., et al.: Shear strength and re-failure characteristics of intact red sandstone and grouting-reinforced body of fractured red sandstone under different shear angles. Minerals. 12(12), 1580 (2022). https://doi.org/10.3390/min12121580

Acknowledgements

This Project is supported by the National Natural Science Foundation of China (Grant No. 51774196).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, Z., Li, C., Meng, Z. et al. Theoretical analysis of grouting reinforcement of surrounding rock with strength drop in deep chamber. Acta Mech 234, 4801–4819 (2023). https://doi.org/10.1007/s00707-023-03629-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-023-03629-9