Abstract

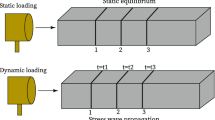

The high impulsive overload when a projectile penetrates multilayered targets affects the performance of explosive charge, which is an important component of many weapons. A tensile stress wave is generated in the charge when the compressive stress wave is reflected from the free surface, which is the main reason of the damage occurrence. Here, the damage behavior of charge under the multiple high impulsive overloads is systematically studied by a strain-rate-dependent cohesive zone model. Therein, a critical δn (normal separation) is determined to describe the macrodamage evolution of charge by contrasting the predictions with the experimental results. Our numerical results show that the δn at the edge of charge is larger than that in the interior and that the angle between the macrodamage area and the transversal direction increases with the targets obliquity. It is found that the maximum δn and the macrodamage proportion during oblique penetration are larger than those during normal penetration. With the increase in the projectile velocity, the maximum δn and the total macrodamage proportion increase, and severe macrodamage area is closer to the tail. As the targets spacing expands, both the maximum δn and the total macrodamage proportion change non-monotonically, while the distance from the severe macrodamage area to the tail expands.

Similar content being viewed by others

References

Stevens, R.: A strength model and service envelope for PBX 9501. Los Alamos National Lab. (LANL), Los Alamos, NM (United States) (2014)

Cui, Y.X., Chen, P.W., Liu, Y.L., Dai, K.D., Zhong, F.P.: Predicted formula of the dynamic increase factor of PBX 9501. Chin. J. Explos. Propellants 38(3), 54–58 (2015)

Chen, J.K., Li, J.L., Zhu, L.M., Li, K.W., Zhao, F., Bai, S.L.: On the tension-induced microcracks’ nucleation in a PBX substitute material under impact compression loading. Int. J. Mech. Sci. 134, 263–272 (2017)

Yang, K., Wu, Y.Q., Huang, F.L.: Damage and hotspot formation simulation for impact-shear loaded PBXs using combined microcrack and microvoid model. Euro. J. Mech. A/Solids 80, 103924 (2020)

Xia, Q.Z., Wu, Y.Q., Huang, F.L.: Effect of interface behaviour on damage and instability of PBX under combined tension-shear loading. Def. Technol. (2022). https://doi.org/10.1016/j.dt.2022.01.010

Huang, K., Yan, J., Shen, R.L., Wan, Y.L., Li, Y.K., Ge, H., Yu, H.J., Guo, L.C.: Investigation on fracture behavior of polymer-bonded explosives under compression using a viscoelastic phase-field fracture method. Eng. Fract. Mech. 266, 108411 (2022)

Guo, Y.C., Liu, R., Chen, P.W., Zhou, B., Hu, G.Y., Han, C., Lv, K.Z., Zhu, S.P.: Mechanical behavior of PBX with different HMX crystal size during die pressing: Experimental study and DEM simulation. Compos. Sci. Technol. 222, 109378 (2022)

Mirkarimi, P.B., Moua, Y., Pease, S.T., Sain, J.D.: Fracture toughness and crack propagation in LX-17 and PBX 9502 insensitive high explosives. Int. J. Solids. Struct. 250, 111721 (2022)

Huang, Y.F., Deng, X.L., Bai, J.S.: Peridynamic investigation of dynamic damage behaviors of PBX confined in spherical steel shells. Mech. Mater. 172, 104389 (2022)

Børvik, T., Langseth, M., Hopperstad, O.S., Malo, K.A.: Perforation of 12 mm thick steels by 20 mm diameter projectiles with flat, hemispherical and conical noses: Part I: experimental study. Int. J. Imp. Eng. 27(1), 19–35 (2002)

Børvik, T., Hopperstad, O.S., Berstad, T., Langseth, M.: Perforation of 12 mm thick steels by 20 mm diameter projectiles with flat, hemispherical and conical noses: Part II: numerical simulations. Int. J. Imp. Eng. 27(1), 37–64 (2002)

Chen, W., Zhang, Q.M., Hu, X.D., Bai, R.Q.: Experimental study on damage to explosive charge by impact load in the process of penetration. Chin. J. Energ. Mater. 17(3), 321–325 (2009)

Li, X., Liu, Y., Sun, Y.: Dynamic mechanical damage and non-shock initiation of a new polymer bonded explosive during penetration. Polymers 12(6), 1342 (2020)

Xu, W.Z., Wang, J.Y., Li, J.L., Huang, H.: Theoretical analysis and simulation for penetration overload of a small size charge. J. Vib. Shock 30(7), 96–100 (2011)

Xu, Z.F., Li, L.L., Qu, K.P.: Study on effects of the buffer device on the anti-overloading safing of explosive charge. Sci. Technol. Eng. 18(6), 179–182 (2015)

Shi, X.H., Dai, K.D., Chen, P.W., Cui, Y.X.: Numerical simulation of dynamic damage of PBX charge during the warhead penetration process. Chin. Meas. Test. 42(10), 138–142 (2016)

Zhang, Z.A., Chen, H.J.: Research on numerical simulation of impact velocity and impact angle to hard target penetration acceleration influence. J. Syst. Simul. 19(11), 2607–2609 (2007)

Wang, W.L., Huang, X.F., Yang, Y.T.: Research on the grain safety during the penetration process of semi-armor-piercing warhead. J. Naval. Aeron. Astron. Univ. 25(1), 79–82 (2010)

Cheng, L.R., Wang, D.W., He, Y.J.: Research on the damage and hot-spot generation in explosive charges during penetration into single- or multi-layer target. Acta. Armamentarii 41(1), 32–39 (2020)

Shao, Y., Zhao, H.P., Feng, X.Q., Gao, H.J.: Discontinuous crack-bridging model for fracture toughness analysis of nacre. J. Mech. Phys. Solids. 60, 1400–1419 (2012)

Shao, Y., Zhao, H.P., Feng, X.Q.: On the flaw tolerance of nacre: a theoretical study. J. R. Soc. Interface 11, 20131016 (2014)

Shen, N., Peng, M.Y., Gu, S.T., Hu, Y.G.: Effects of the progressive damage interphase on the effective bulk behavior of spherical particulate composites. Acta. Mech. 232, 423–437 (2021)

Fang, C., Guo, X., Weng, G.J., Li, J.H., Chen, G.: Simulation of ductile fracture of zirconium alloys based on triaxiality dependent cohesive zone model. Acta. Mech. 232, 3723–3736 (2021)

Zhu, Z.Q., Wan, J., Wu, T.X., Huang, P.Y.: Effect of electrode processing on the stability of electrode structure. Acta. Mech. 233, 2471–2484 (2022)

Hou, J.L., Lu, X., Li, Q.: Application of general regression neural network in identifying interfacial parameters under mixed-mode fracture. Acta. Mech. 233, 3909–3921 (2022)

Shi, X.H., Yu, C.X., Dai, K.D., Cui, Y.X., Chen, H.: The influence of nose shape to dynamic damage of PBX charge during the penetration process. J. Proj. Rock. Missil. Guidance 39(3), 81–85 (2019)

Bi, C., Guo, X., Qu, K.P., Shen, F.: Numerical simulation of charge damage during oblique penetration. Chin. J. Explos. Propellants 45(3), 383–387 (2022)

Sun, B.P., Duan, Z.P., Wan, J.L., Liu, Y., Ou, Z.C., Huang, F.L.: Investigation on ignition of an explosive charge in a projectile during penetration based on visco-SCRAM model. Expl. Shock Waves 35(5), 689–695 (2015)

Zhang, X.L., Wang, H., Tan, Z.J., Wang, Z.M.: Relevance between aspect ratio of projectile and boundary effect of concrete target. J. Ordnance Equip. Eng. 39(4), 11–13 (2018)

Johnson, G.R., Cook, W.H.: A constitutive model and data for metals subjected to large strains, high strain rates, and high temperatures. In: Proceedings of the 7th Int. Symposium on Ballistics, The Hague, The Netherlands (1983)

Johnson, G.R., Cook, W.H.: Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 21(1), 31–48 (1985)

Yu, P.: Investigation on the dynamic characteristics and constitutive model of polycarbonate of aircraft. South Chin. Univ. Technol, Guangzhou (2014)

Chen, G., Chen, X.W., Chen, Z.F., Qu, M.: Simulations of A3 steel blunt projectiles impacting 45 steel plates. Expl. Shock Waves 27(5), 390–397 (2007)

Li, S.: Study on the dynamic mechanical behavior and fracture mechanism of 35CrMnSi under shock loading. North Univ. China, Shanxi (2015)

Cui, Y.X.: Study on damage and fracture of polymer bonded explosives under impact loading. Beijing: Beijing Inst. Technol. (2017)

Yang, K., Wu, Y.Q., Huang, F.L.: Numerical simulations of microcrack-related damage and ignition behavior of mild-impacted polymer bonded explosives. J. Hazard. Mater. 356, 34–52 (2018)

Zhou, F.H., Molinari, J.F.: On the rate-dependency of dynamic tensile strength of a model ceramic system. Comput. Method. Appl. Mech. Eng. 194(116), 1691709 (2005)

Anvari, M., Scheider, I., Thaulow, C.: Simulation of dynamic ductile crack growth using strain-rate and triaxiality-dependent cohesive elements. Eng. Fract. Mech. 73(15), 2210–2228 (2006)

Rosa, A.L., Yu, R.C., Ruiz, G., Saucedo, L., Sousa, J.L.A.O.: A loading rate dependent cohesive model for concrete fracture. Eng. Fract. Mech. 82, 195–208 (2012)

Salih, S., Davey, K., Zou, Z.: Rate-dependent elastic and elasto-plastic cohesive zone models for dynamic crack propagation. Int. J. Solids. Struct. 90, 95–115 (2016)

Wang, K.K., Zhao, L.B., Hong, H.M., Zhang, J.Y.: A strain-rate-dependent damage model for evaluating the low velocity impact induced damage of composite laminates. Compos. Struct. 201, 995–1003 (2018)

Prakash, C., Gunduz, I.E., Oskay, C., Tomar, V.: Effect of interface chemistry and strain rate on particle-matrix delamination in an energetic material. Eng. Fract. Mech. 191, 46–64 (2018)

Tang, L.W., Zhou, W., Liu, X.H., Ma, G., Chen, M.X.: Three-dimensional mesoscopic simulation of the dynamic tensile fracture of concrete. Eng. Fract. Mech. 211, 269–281 (2019)

Borges, C.S.P., Nunes, P.D.P., Akhavan-Safar, A., Marques, E.A.S., Carbas, R.J.C., Alfonso, L., Silva, L.F.M.: A strain rate dependent cohesive zone element for mode I modeling of the fracture behavior of adhesives. Proc. Inst. Mech. Eng., Part L: J. Mater: Design. Appl 234(4), 610–621 (2020)

Li, D., Wei, D.M.: Rate-dependent cohesive zone model for fracture simulation of soda-lime glass. Materials 13(3), 749 (2020)

Brewer, J.C., Lagace, P.A.: Quadratic stress criterion for initiation of delamination. J. Compos. Mater. 22(12), 1141–1155 (1988)

Cui, W.C., Wisnom, M.R., Jones, M.: A comparison of failure criteria to predict delamination of unidirectional glass/epoxy specimens waisted through the thickness. Composites 23(3), 158–166 (1992)

ABAQUS/Explicit. ABAQUS Theory Manual and User’s Manual, version 6.11, Dassault (2014).

Marzi, S., Hesebeck, O., Brede, M., Kleiner, F.: A rate-dependent cohesive zone model for adhesively bonded joints loaded in mode I. J. Adhes. Sci. Technol. 23(6), 881–898 (2009)

Zhou, R.X., Chen, H.M., Lu, Y.: Mesoscale modelling of concrete under high strain rate tension with a rate-dependent cohesive interface approach. Int. J. Imp. Eng. 139, 103500 (2020)

Williams, M.L., Landel, R.F., Ferry, J.D.: The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J. Am. Chem. Soc. 77(14), 3701–3707 (1955)

Zhou, Z.B., Chen, P.W., Huang, F.L.: Study on dynamic fracture and mechanical properties of a PBX simulant by using DIC and SHPB method. AIP Conference Proceedings. Am. Ins. Phy. 1426(1), 665–668 (2012)

Miller, O., Freund, L.B., Needleman, A.: Modeling and simulation of dynamic fragmentation in brittle materials. Int. J. Fract. 96(2), 101–125 (1999)

Snozzi, L., Caballero, A., Molinari, J.F.: Influence of the meso-structure in dynamic fracture simulation of concrete under tensile loading. Cement Concrete Res. 41(11), 1130–1142 (2011)

Saksala, T.: Numerical modelling of concrete fracture processes under dynamic loading: Meso-mechanical approach based on embedded discontinuity finite elements. Eng. Fract. Mech. 201, 28297 (2018)

Acknowledgements

The authors wish to thank two anonymous reviewers for their helpful comments. This work was supported by Opening and Collaboration Renovation Fund of Xi’an Modern Chemistry Research Institute (Grant no. SYJJ41). Zhu also acknowledges the National Natural Science Foundation of China (Grant no. 12072317).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bi, C., Guo, X., Wang, A.H. et al. Strain-rate-dependent cohesive zone modelling of charge damage behavior when a projectile penetrates multilayered targets. Acta Mech 234, 2869–2887 (2023). https://doi.org/10.1007/s00707-023-03541-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-023-03541-2