Abstract

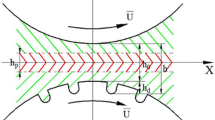

Estimation of friction and wear is a challenging problem, and finding a way to reduce them has been a concern for many years. One of the most interesting ways is to make small dimples on the surface, which increases the preservation of the lubricant in the contact area. Grease behavior is non-Newtonian lubricant, and each type of grease has its unique behavior. In this research, a model for the behavior of grease as a lubricant on surfaces is investigated. Non-conformal surfaces are considered, and their deformation due to the application of load is assumed by elastohydrodynamic contact condition. The film thickness and pressure distribution in the lubricant layer are extracted by modeling the grease behavior. The model considered the transient phenomenon during passing pin over dimple. The effect of parameters such as the diameter and depth of the dimples, the applied load, and the speed of in-contact surfaces can be considered in the model. Finally, a friction estimation formula is developed with these findings. The experimental samples were then examined using a pin-on-disk test apparatus. Measuring friction on textured and flat surfaces was the criterion for comparing the performance of these dimples. The numerical results and experimental results are consistent. The model can successfully estimate the friction coefficient by a 4.5 percent average error. Using textured surfaces shows about 7 percent less friction compared to flat surfaces.

Similar content being viewed by others

References

Venner, C.H., van Zoelen, M.T., Lugt, P.M.: Thin layer flow and film decay modeling for grease lubricated rolling bearings. Tribol. Int. 47, 175–187 (2012)

Otsu, T., Nagata, Y., Sugimura, J., Glovnea, R.: Cavitation phenomena in pure-sliding grease EHL Films. STLE/ASME 2010 International Joint Tribology Conference San Francisco, California, USA, pp. 17–20, (2010)

Lugt, P.M.: A review on grease lubrication in rolling bearings. Tribol. Trans. 52(4), 470–480 (2009)

Morales-Espejel, G.E., Lugt, P.M., Pasaribu, H.R., Cen, H.: Film thickness in grease lubricated slow rotating rolling bearings. Tribol. Int. 74, 7–19 (2014)

Kauzlarich, J.J., Greenwood, J.A.: Inlet shear heating in elastohydrodynamic lubrication. Trans. ASME J. Lubr. Technol. 95, 417–426 (1973)

Jonkisz, W., Krzeminski-Freda, H.: The properties of elastohydrodynamic grease films. Wear 77, 277–285 (1979)

Cheng, J.: Elastohydrodynamic grease lubrication theory and numerical solution inline contacts. Tribol. Trans. 37(4), 711–718 (1994)

Sugimura, J., Akiyama, M.: Study of non-steady state grease lubrication with fluorescence microscope. Elsevier Tribol. Series 39, 285–294 (2001)

Lu, X., Khonsari, M.M.: An experimental study of grease-lubricated journal bearings undergoing oscillatory motion. J. Tribol. 129(3), 640–646 (2007)

Lu, X., Khonsari, M.M.: An experimental investigation of grease-lubricated journal bearings. J. Tribol. 129(1), 84–90 (2006)

Cousseau, T., Björling, M., Graça, B., Campos, A., Seabra, J., Larsson, R.: Film thickness in a ball-on-disk contact lubricated with greases, bleed oils and base oils. Tribol. Int. 53, 53–60 (2012)

Akbarzadeh, S., Khonsari, M.M.: Effect of surface pattern on stribeck curve. Tribol. Lett. 37, 477–486 (2010). https://doi.org/10.1007/s11249-009-9543-2

Etsion, I., Burstein, L.: A model for mechanical seals with regular microsurface structure. Tribol. Trans. 39, 677–683 (1996)

Etsion, I.: State of the art in laser surface texturing. J. Tribol. 127, 248–253 (2005)

Dobrica, M.B., Fillon, M., Pascovici, M.D., Cicone, T.: Optimizing surface texture for hydrodynamic lubricated contacts using a mass-conserving numerical approach. J. Eng. Tribol. 224, 737–750 (2010)

Fowell, M.T., Medina, S., Olver, A.V., Spikes, H.A., Pegg, I.G.: Parametric study of texturing in convergent bearings. Tribol. Int. 52, 7–16 (2012)

Coblas, D.G., Fatu, A., Hajjam, M.: Manufacturing textured surfaces: state of art and recent developments. Proc. Inst. Mech. Eng. Part J: J. Eng. Tribol. 229, 3–29 (2015)

Costa, H.L., Hutchings, I.M.: Some innovative surface texturing techniques for tribological purposes. Proc. Mech. Eng. Part J-J. Eng. Tribol. 229, 429–448 (2015)

Nanbu, T., Ren, N., Yasuda, Y., Zhu, D., Wang, Q.J.: Micro-textures in concentrated conformal-contact lubrication: effects of texture bottom shape and surface relative motion. Tribol. Lett. 29, 241–252 (2008)

Shen, C., Khonsari, M.M.: Effect of dimple’s internal structure on hydrodynamic lubrication. Tribol. Lett. 52, 415–430 (2013)

Caramia, G., Carbone, G., De Palma, P.: Hydrodynamic lubrication of micro-textured surfaces: two dimensional CFD-analysis. Tribol. Int 88, 162–169 (2015)

Han, J., Fang, L., Sun, J., Ge, S.: Hydrodynamic lubrication of microdimple textured surface using three-dimensional CFD. Tribol. Trans. 53, 860–870 (2010)

Gropper, D., Harvey, T.J., Wang, L.: Numerical analysis and optimization of surface textures for a tilting pad thrust bearing. Tribol. Int. 124, 134–144 (2018)

Gropper, D., Harvey, T.J., Wang, L.: A numerical model for design and optimization of surface textures for tilting pad thrust bearings. Tribol. Int. 119, 190–207 (2018)

Rahmani, R., Rahnejat, H.: Enhanced performance of optimised partially textured load bearing surfaces. Tribol. Int. 117, 272–282 (2018)

Meng, X., Gu, Ch., Xie, Y.: Elasto-plastic contact of rough surfaces: a mixed-lubrication model for the textured surface analysis. Meccanica 52(7), 1541–1559 (2017)

Rom, M., Müller, S.: An effective Navier-Stokes model for the simulation of textured surface lubrication. Tribol. Int. 124, 247–258 (2018)

Taee, M., Torabi, A., Akbarzadeh, S., Khonsari, M.M., Badrossamay, M.: On the performance of EHL contacts with textured surfaces. Tribol. Lett. 65, 85 (2017)

Xie, Y., Li, S., Hu, X., Bishara, B.: An adhesive Gurtin-Murdoch surface hydrodynamics theory of moving contact line and modeling of droplet wettability on soft substrates. J. Comput. Phys. 456, 111074 (2022)

Hua, X., Puoza, J.C., Zhang, P., Yin, B., Xie, X., Din, J.: Numerical simulation and experimental analysis of grease friction properties on textured surface. Iran J. Sci. Technol. Trans. Mech. Eng. (2018). https://doi.org/10.1007/s40997-018-0162-0

Sisko, A.W.: The flow of lubricating greases. Ind. Eng. Chem. 50(1789–1), 792 (1958)

Bauer, W.H., Finkelstein, A.D., M’iberley, S.E.: Flow properties of lithium stearate-oil hlodel greases as functions of soap concentration and temperature. Proc. ASLE 3, 215–224 (1960)

Herschel, W.H., Bulkley, R.: Measurement of consistency as applied to rubber-benzene solutions. Proc. ASTM 26, 621–633 (1926)

Mahncke, H.E., Tabor, W.: A simple demonstration of flow type in greases. Lub. Evg. 11, 22–28 (1955)

Dowson, D., Higginson, G.R.: Elasto-Hydrodynamic Lubrication. Pergamon Press, New York (1966)

Karthikeyan, B.K., Teodorescu, M., Rahnejat, H., Rothberg, S.J.: Thermo-elastohydrodynamics of grease-lubricated concentrated point contacts. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 224(3), 683–695 (2010)

Torabi, A., Akbarzadeh, S., Azami, B.: Transient numerical modeling and experimental investigation of the effect of surface texture on elastohydrodynamic lubrication. Amirkabir J. Mech. Eng. 53, 3201–3212 (2021). https://doi.org/10.22060/mej.2020.18106.6737

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Torabi, A., Alidousti, M.H. Numerical and experimental study of elastohydrodynamic grease lubrication of dimple textured surfaces. Acta Mech 234, 2919–2931 (2023). https://doi.org/10.1007/s00707-023-03535-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-023-03535-0