Abstract

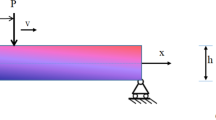

This paper presents a finite element model for an exponentially graded, isotropic, Cosserat elastic material. The presented research focuses on conducting a parametric study to investigate the influence of the torsional characteristic length on the torsional properties of cylinders in pure torsion, with exponential grading along the axis of the cylinders. A mesh sensitivity study is performed, as well as a study on the influence of the mentioned functional grading on the torsional properties of the cylinders. Lastly, an investigation into the influence of the torsional characteristic length and specimen size (cylinder diameter) is performed to confirm the presence of a size effect, commonly discussed in the literature. The findings of the studies are presented, along with their implications.

Similar content being viewed by others

References

Hashin, Z.: Analysis of composite materials-a survey (1983)

Pindera, M., Arnold, S., Aboudi, J., Hui, D.: Use of Composities in Functionally Graded Materials. Kidlington ., Pergamon-Elsevier Science Ltd The Boulevard, Langford Lane (1994)

Mahamood, R.M., Akinlabi, E.T., Shukla, M., Pityana, S.L.: Functionally graded material: an overview (2012)

Wang, S.: Fracture mechanics for delamination problems in composite materials. Journal of composite materials 17(3), 210–223 (1983)

Asghari, M., Ahmadian, M., Kahrobaiyan, M., Rahaeifard, M.: On the size-dependent behavior of functionally graded micro-beams. Materials & Design (1980-2015) 31(5), 2324–2329 (2010)

Niino, M.: Functionally gradient materials as thermal barrier for space plane. J. Jpn. Composite Mater. 13, 257–264 (1987)

Udupa, G., Rao, S.S., Gangadharan, K.: Functionally graded composite materials: an overview. Procedia Materials Science 5, 1291–1299 (2014)

Tsui, Y., Howard, S., Clyne, T.: The effect of residual stresses on the debonding of coatings-ii. an experimental study of a thermally sprayed system. Acta metallurgica et materialia 42(8), 2837–2844 (1994)

Koizumi, M.: Fgm activities in Japan. Composites Part B: Engineering 28(1–2), 1–4 (1997)

Rueger, Z., Lakes, R.S.: Strong cosserat elastic effects in a unidirectional composite. Zeitschrift für angewandte Mathematik und Physik 68(3), 1–9 (2017)

Anderson, W., Lakes, R.: Size effects due to cosserat elasticity and surface damage in closed-cell polymethacrylimide foam. Journal of Materials Science 29(24), 6413–6419 (1994)

Calvetti, F., Combe, G., Lanier, J.: Experimental micromechanical analysis of a 2d granular material: relation between structure evolution and loading path. Mechanics of Cohesive-frictional Materials: An International Journal on Experiments, Modelling and Computation of Materials and Structures 2(2), 121–163 (1997)

Münch, I., Neff, P., Wagner, W.: Transversely isotropic material: nonlinear cosserat versus classical approach. Continuum Mechanics and Thermodynamics 23(1), 27–34 (2011)

Lakes, R., Drugan, W.: Bending of a cosserat elastic bar of square cross section: Theory and experiment. Journal of Applied Mechanics 82(9) (2015)

Fleck, N., Muller, G., Ashby, M.F., Hutchinson, J.W.: Strain gradient plasticity: theory and experiment. Acta Metallurgica et materialia 42(2), 475–487 (1994)

Xu, Y., Li, M., Huo, X.: Size effect of bending properties of zirconia ceramics based on cosserat theory. In: Proceedings of the International Workshop on Materials, Chemistry and Engineering-Volume 1, pp. 371–377 (2018)

Huang, W., Xu, K.: Characteristic lengths in cosserat continuum modeling of granular materials. Engineering computations (2015)

Lakes, R.S., Benedict, R.L.: Noncentrosymmetry in micropolar elasticity. International Journal of Engineering Science 20(10), 1161–1167 (1982)

Diepolder, W., Mannl, V., Lippman, H.: The cosserat continuum, a model for grain rotations in metals? International journal of plasticity 7(4), 313–328 (1991)

Mora, R., Waas, A.M.: Measurement of the cosserat constant of circular-cell polycarbonate honeycomb. Philosophical Magazine A 80(7), 1699–1713 (2000)

Tang, H.-X., Hu, Z.-L.: Application of the cosserat continua to numerical studies on the properties of the materials. Mechanics of Advanced Materials and Structures 24(10), 797–808 (2017)

Sakhaei, A.H., Erland, S., Dodwell, T.J.: A finite deformation cosserat continuum model for uncured carbon fibre composites. Mechanics of Materials 151, 103611 (2020)

Yoon, H.S., Katz, J.L.: Is bone a cosserat solid? Journal of Materials Science 18(5), 1297–1305 (1983)

Reddy, G.K., Venkatasubramanian, N.K.: On the flexural rigidity of a micropolar elastic circular cylindrical tube. International Journal of Engineering Science 17(9), 1015–1021 (1979)

Papamichos, E.: Continua with microstructure: Cosserat theory. European journal of environmental and civil engineering 14(8–9), 1011–1029 (2010)

Kapiturova, M., Gracie, R., Potapenko, S.: Simulation of cracks in a Cosserat medium using the extended finite element method. Mathematics and Mechanics of Solids 21(5), 621–635 (2016)

Potapenko, S.: A generalized Fourier approximation in anti-plane Cosserat elasticity. Journal of Elasticity 81(2), 159–177 (2005)

Potapenko, S., Schiavone, P., Mioduchowski, A.: Antiplane shear deformations in a linear theory of elasticity with microstructure. Zeitschrift für angewandte Mathematik und Physik ZAMP 56(3), 516–528 (2005)

Potapenko, S.: Fundamental sequences of functions in the approximation of the solution to the mixed boundary-value problem in anti-plane Cosserat elasticity. Acta mechanica 177(1), 61–69 (2005)

Shmoylova, E., Potapenko, S., Rothenburg, L.: Boundary element analysis of stress distribution around a crack in plane micropolar elasticity. International journal of engineering science 45(2–8), 199–209 (2007)

Nowacki, W.: Theory of Micropolar Elasticity. Springer (1972)

Eringen, A.C.: Microcontinuum Field Theories: I. Springer, Foundations and Solids (2012)

Eringen, A.C.: Theory of micropolar elasticity. In: Microcontinuum Field Theories, pp. 101–248. Springer (1999)

Barrage, R., Potapenko, S., Polak, M.A.: On the elliptic regularity of exponentially graded composites with microstructure. Zeitschrift Angewandte Mathematik und Physik, to appear (2022) https://doi.org/10.1007/s00033-022-01786-w

Abaqus, C.: Analysis user’s manual, Version 6.12. ABAQUS (2012)

Martínez-Pañeda, E.: On the finite element implementation of functionally graded materials. Materials 12(2), 287 (2019)

Cowper, G.: Gaussian quadrature formulas for triangles. International Journal for Numerical Methods in Engineering 7(3), 405–408 (1973)

Shi, J., Chopp, D., Lua, J., Sukumar, N., Belytschko, T.: Abaqus implementation of extended finite element method using a level set representation for three-dimensional fatigue crack growth and life predictions. Engineering Fracture Mechanics 77(14), 2840–2863 (2010)

Eremeyev, V.A., Pietraszkiewicz, W.: Material symmetry group of the non-linear polar-elastic continuum. International Journal of Solids and Structures 49(14), 1993–2005 (2012)

Liu, Q., Li, J., Liu, J.: Paraview visualization of abaqus output on the mechanical deformation of complex microstructures. Computers & geosciences 99, 135–144 (2017)

Acknowledgements

Authors wish to thank Natural Science and Engineering Research Council of Canada for their financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Barrage, R., Potapenko, S. & Polak, M.A. Influence of microstructural characteristic torsion length on exponentially graded cylinders in torsion. Acta Mech 234, 1553–1569 (2023). https://doi.org/10.1007/s00707-022-03436-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-022-03436-8