Abstract

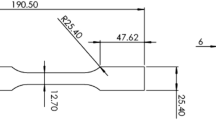

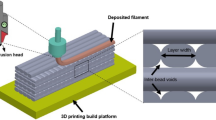

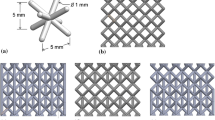

The mechanical property of 3D-printed components often exhibits anisotropic behaviors and a strong dependence on printing orientations and process parameters. In this study, computational models based on microstructures of 3D-printed ABS polymers are developed using micromechanics of a representative volume element (RVE) to investigate the orthotropic elastic properties. Two finite element models, based on Micro-CT or CAD geometry, with different raster angles: \(0^{\circ }\), \(30^{\circ }\), \(45^{\circ }\), and \(60^{\circ }\) (corresponding to the layups of \(0^{\circ }/90^{\circ }\), \(30^{\circ }/{-}60^{\circ }\), \(45^{\circ }/{-}45^{\circ }\), and \(60^{\circ }/{-}30^{\circ }\)), are considered. The Micro-CT model useds the realistic geometry of a 3D-printed cube reconstructed from Micro-CT scans. The CAD model useds periodic layers and filaments with sizes specified according to the dimensional statistics from the Micro-CT model, including bond width, layer height, filament width, and total porosity. All models are subjected to six independent load cases of macroscopically uniform boundary conditions (BCs) admitted by the Hill–Mandel condition to obtain a fully orthotropic elastic stiffness matrix. Scale-dependent bounds from those BCs are used to establish the convergence of RVE responses. The theoretical method of Mori–Tanaka homogenization is also employed to verify numerical predictions. The results of both Micro-CT and CAD models are close to each other and agree well with experimental results in the literature. Parametric studies are further performed in CAD models by varying layer height, filament width, and bond width to investigate their effects on the orthotropic elastic properties. It is found that the porosity plays a significant role, and more porosity leads to larger elastic anisotropy in 3D-printed materials.

Similar content being viewed by others

References

Li, H., Wang, T.T., Sun, J., Yu, Z.: The effect of process parameters in fused deposition modelling on bonding degree and mechanical properties. Rapid Prototyp. J. 24(1), 80–92 (2018). https://doi.org/10.1108/RPJ-06-2016-0090

Jiang, M., Ostoja-Starzewski, M., Jasiuk, I.: Scale-dependent bounds on effective elastoplastic response of random composites. J. Mech. Phys. Solids 49(3), 655–673 (2001). https://doi.org/10.1016/S0022-5096(00)00034-X

Abbott, A.C., Tandon, G.P., Bradford, R.L., Koerner, H., Baur, J.W.: Process-structure-property effects on ABS bond strength in fused filament fabrication. Addit. Manuf. 19, 29–38 (2018). https://doi.org/10.1016/j.addma.2017.11.002

Sun, C.T., Vaidya, R.S.: Prediction of composite properties from a representative volume element. Compos. Sci. Technol. 56(2), 171–179 (1996). https://doi.org/10.1016/0266-3538(95)00141-7

Casavola, C., Cazzato, A., Moramarco, V., Pappalettere, C.: Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory. Mater. Des. 90, 453–458 (2016). https://doi.org/10.1016/j.matdes.2015.11.009

Hazanov, S.: On apparent properties of nonlinear heterogeneous bodies smaller than the representative volume. Acta Mech. 134(3), 123–134 (1999). https://doi.org/10.1007/BF01312651

Holdsworth, D.W., Thornton, M.M.: Micro-CT in small animal and specimen imaging. Trends Biotechnol. 20(8), 34–39 (2002). https://doi.org/10.1016/S0167-7799(02)02004-8

Domingo-Espin, M., Puigoriol-Forcada, J.M., Garcia-Granada, A.A., Llumà, J., Borros, S., Reyes, G.: Mechanical property characterization and simulation of fused deposition modeling Polycarbonate parts. Mater. Des. 83, 670–677 (2015). https://doi.org/10.1016/j.matdes.2015.06.074

Tymrak, B.M., Kreiger, M., Pearce, J.M.: Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 58, 242–246 (2014). https://doi.org/10.1016/j.matdes.2014.02.038

Bellini, A., Güçeri, S.: Mechanical characterization of parts fabricated using fused deposition modeling. Rapid Prototyp. J. 9(4), 252–264 (2003). https://doi.org/10.1108/13552540310489631

Zhang, W., Cotton, C., Sun, J., Heider, D., Gu, B., Sun, B., Chou, T.W.: Interfacial bonding strength of short carbon fiber/acrylonitrile-butadiene-styrene composites fabricated by fused deposition modeling. Compos. Part B Eng. 137(2017), 51–59 (2018)

Alaimo, G., Marconi, S., Costato, L., Auricchio, F.: Influence of meso-structure and chemical composition on FDM 3D-printed parts. Compos. B Eng. 113, 371–380 (2017). https://doi.org/10.1016/j.compositesb.2017.01.019

Faes, M., Ferraris, E., Moens, D.: Influence of inter-layer cooling time on the quasi-static properties of ABS components produced via fused deposition modelling. Procedia CIRP 42(Isem Xviii), 748–753 (2016)

Pahr, D.H., Zysset, P.K.: Influence of boundary conditions on computed apparent elastic properties of cancellous bone. Biomech. Model. Mechanobiol. 7(6), 463–476 (2008). https://doi.org/10.1007/s10237-007-0109-7

Liu, X., Shapiro, V.: Homogenization of material properties in additively manufactured structures. Comput. Aided Des. 78, 71–82 (2016). https://doi.org/10.1016/j.cad.2016.05.017

Cantrell, J.T., Rohde, S., Damiani, D., Gurnani, R., DiSandro, L., Anton, J., Ifju, P.G.: Experimental characterization of the mechanical properties of 3D-printed ABS and polycarbonate parts. Rapid Prototyp. J. 23(4), 811–824 (2017). https://doi.org/10.1108/RPJ-03-2016-0042

Croccolo, D., De Agostinis, M., Olmi, G.: Experimental characterization and analytical modelling of the mechanical behaviour of fused deposition processed parts made of ABS-M30. Comput. Mater. Sci. 79, 506–518 (2013). https://doi.org/10.1016/j.commatsci.2013.06.041

Sun, Q., Rizvi, G.M., Bellehumeur, C.T., Gu, P.: Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 14(2), 72–80 (2008). https://doi.org/10.1108/13552540810862028

Zhang, Y., Mamadapur, M.S., Wang, J.: Constitutive modelling for fused deposition modelling of acrylonitrile butadiene styrene (ABS) under elastic response. Int. J. Rapid Manuf. 5(1), 76–94 (2015). https://doi.org/10.1504/IJRAPIDM.2015.073549

Coogan, T.J., Kazmer, D.O.: Bond and part strength in fused deposition modeling. Rapid Prototyp. J.urnal 23, 414–422 (2017)

Hill, R.: Elastic properties of reinforced solids: some theoretical principles. J. Mech. Phys. Solids 11, 357–372 (1963)

Tuan, H.S., Hutmacher, D.W.: Application of micro CT and computation modeling in bone tissue engineering. CAD Comput. Aided Des. 37(11), 1151–1161 (2005). https://doi.org/10.1016/j.cad.2005.02.006

Ostoja-Starzewski, M.: Microstructural Randomness and Scaling in Mechanics of Materials. Chapman & Hall/CRC Press, Boca Raton (2008)

Ranganathan, S.I., Murshed, M.R., Costa, L.: Heterogeneous anisotropy Index and scaling in two-phase random polycrystals. Acta Mech. 229(6), 2631–2646 (2018). https://doi.org/10.1007/s00707-018-2114-6

Ho, S.T., Hutmacher, D.W.: A comparison of micro CT with other techniques used in the characterization of scaffolds. Biomaterials 27(8), 1362–1376 (2006). https://doi.org/10.1016/j.biomaterials.2005.08.035

Kwok, K., Pellegrino, S.: Micromechanics models for viscoelastic plain-weave composite tape springs. AIAA J> 55(1), 309–321 (2017). https://doi.org/10.2514/1.J055041

Stratasys: ABSplus Properties, 3–4 (2008). http://www.stratasys.com/materials/fdm/absplus. Accessed 20 Feb 2019

SIMULIA: SIMULIA Abaqus Documentation (2018). https://help.3ds.com/2018/English/DSSIMULIA_Established/SIMULIA_Established_FrontmatterMap/DSDocAbaqus.htm?ContextScope=all

DeCicco, A., Jessica Faust: Effects of build Parameters on Additive Materials, (October), 193 (2013). https://web.wpi.edu/Pubs/E-project/Available/E-project-103013-102149/unrestricted/NAG1301-_Effects_of_Build_Parameters_on_Additive_Materials-Public.pdf

Hambali, R.H., Celik, K., Smith, P., Rennie, A., Ucar, M.: Effect of build orientation on FDM parts: a case study for validation of deformation behaviour by FEA. In: International Conference on Design and Concurrent Engineering, (September), pp. 20–21 (2010)

Melenka, G.W., Schofield, J.S., Dawson, M.R., Carey, J.P.: Evaluation of dimensional accuracy and material properties of the MakerBot 3D desktop printer. Rapid Prototyp. J. 21(5), 618–627 (2015). https://doi.org/10.1108/RPJ-09-2013-0093

Quan, Z., Larimore, Z., Qin, X., Yu, J., Mirotznik, M., Byun, J.-H., Oh, Y., Chou, T.-W.: Microstructural characterization of additively manufactured multi-directional preforms and composites via X-ray micro-computed tomography. Compos. Sci. Technol. 131, 48–60 (2016)

Zanini, F., Sbettega, E., Carmignato, S.: X-ray computed tomography for metal additive manufacturing: challenges and solutions for accuracy enhancement. Procedia CIRP 75, 114–118 (2018)

Liu, T., Guessasma, S., Zhu, J., Zhang, W., Nouri, H., Belhabib, S.: Microstructural defects induced by stereolithography and related compressive behaviour of polymers. J. Mater. Process. Technol. 251, 37–46 (2017)

Acknowledgements

The authors are grateful to Dr. Hedi Nouri from IMT Lille-Douai (France) for technical assistance in X-ray micro-tomography and to Dr. Sofiane Belhabib from University of Nantes (France) for assistance in the 3D printing campaign. JL would like to acknowledge the financial support provided by the start-up funds and multidisciplinary seed funds at the University of Massachusetts Dartmouth.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Biswas, P., Guessasma, S. & Li, J. Numerical prediction of orthotropic elastic properties of 3D-printed materials using micro-CT and representative volume element. Acta Mech 231, 503–516 (2020). https://doi.org/10.1007/s00707-019-02544-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-019-02544-2