Abstract

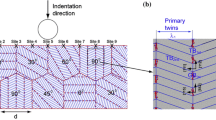

Molecular dynamics simulation of nano-indentation of single-crystal and bicrystal FCC aluminum is performed. The role of crystallographic orientation during nano-indentation of single-crystal aluminum is assessed. Then, the influence of the presence of a grain boundary is analyzed by adding high-angle symmetric tilt boundaries of Σ5<210>/(100) and Σ5<310>/(100) parallel to the surface on which the indentation is performed. Furthermore, in both cases, the size of the indenter is changed to investigate how the surface curvature of the indenter affects the nano-indentation process. The results suggest that in each crystallographic orientation, the presence of a grain boundary increases the required force for indentation, while the distance of a grain boundary from the indentation surface could affect the increase in the required force. Simulations prove that the grain boundary acts as a source of generation and emission of dislocations and restricts the penetration of the indenter by limiting the slip band formation and plastic deformation. The dislocation emission from the grain boundary restricts the penetration of the indenter and limits the formation of the octahedral slip systems of type {111}<110> and consequently increases the required force for indentation in bicrystals.

Similar content being viewed by others

References

Salehinia I., Wang J., Bahr D.F., Zbib H.M.: Molecular dynamics simulations of plastic deformation in Nb/NbC multilayers. Int. J. Plast. 59(0), 119–132 (2014). doi:10.1016/j.ijplas.2014.03.010

Matsumoto R., Nakagaki M., Nakatani A., Kitagawa H.: Molecular-dynamics study on crack growth behavior relevant to crystal nucleation in amorphous metal. CMES 9, 75–84 (2005)

Yu, H.-L., Lu, C., Tieu, K., Deng, G.-Y.: A numerical model for simulation of crack initiation around inclusion under tensile load. J. Comput. Theor. Nanosci. 9, 1745–1749 (2012)

Tomohito T., Yoji S.: Atomistic simulations of elastic deformation and dislocation nucleation in Al under indentation-induced stress distribution. Model. Simul. Mater. Sci. Eng. 14(5), S55 (2006)

Verkhovtsev A.V., Yakubovich A.V., Sushko G.B., Hanauske M., Solov’yov A.V.: Molecular dynamics simulations of the nanoindentation process of titanium crystal. Comput. Mater. Sci. 76(0), 20–26 (2013). doi:10.1016/j.commatsci.2013.02.015

Huo D., Liang Y., Cheng K.: An investigation of nanoindentation tests on the single crystal copper thin film via an atomic force microscope and molecular dynamics simulation. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 221(2), 259–266 (2007). doi:10.1243/0954406jmes448

Nair A.K., Parker E., Gaudreau P., Farkas D., Kriz R.D.: Size effects in indentation response of thin films at the nanoscale: a molecular dynamics study. Int. J. Plast. 24(11), 2016–2031 (2008). doi:10.1016/j.ijplas.2008.01.007

Kim K.J., Yoon J.H., Cho M.H., Jang H.: Molecular dynamics simulation of dislocation behavior during nanoindentation on a bicrystal with a Σ = 5 (210) grain boundary. Mater. Lett. 60(28), 3367–3372 (2006). doi:10.1016/j.matlet.2006.03.020

Fang T.-H., Wu J.-H.: Molecular dynamics simulations on nanoindentation mechanisms of multilayered films. Comput. Mater. Sci. 43(4), 785–790 (2008). doi:10.1016/j.commatsci.2008.01.066

Liao M.-L., Weng M.-H., Ju S.-P., Chiang H.-J.: Molecular dynamics simulation on the nanoindentation behavior of a copper bilayered thin film. Chin. J. Catal. 29(11), 1122–1126 (2008). doi:10.1016/S1872-2067(09)60012-7

Plimpton S.: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995)

Stukowski A.: Visualization and analysis of atomistic simulation data with OVITO—the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2010). doi:10.1088/0965-0393/18/1/015012

Mishin, Y., Farkas, D., Mehl, M.J., Papaconstantopoulos, D.A.: Interatomic potentials for monoatomic metals from experimental data and ab initio calculations. Phys. Rev. B 59(5), 3393 (1999)

Nejadseyfi O., Shokuhfar A.: Molecular dynamics simulation of the effects of crystal orientation and grain boundary misorientation angle on the nano-crack growth. J. Comput. Theor. Nanosci. 11(10), 2199–2207 (2014)

Liu T., Groh S.: Atomistic modeling of the crack–void interaction in α-Fe. Mater. Sci. Eng. A 609(0), 255–265 (2014). doi:10.1016/j.msea.2014.05.005

Yuan Y., Sun T., Zhang J., Yan Y.: Molecular dynamics study of void effect on nanoimprint of single crystal aluminum. Appl. Surf. Sci. 257(16), 7140–7144 (2011). doi:10.1016/j.apsusc.2011.03.073

Meguid S.A., Al Jahwari F.: Modeling the pullout test of nanoreinforced metallic matrices using molecular dynamics. Acta Mech. 225(4–5), 1267–1275 (2014). doi:10.1007/s00707-013-1065-1

Ju S.P., Wang C.T., Chien C.H., Huang J.C., Jian S.R.: The nanoindentation responses of nickel surfaces with different crystal orientations. Mol. Simul. 33(11), 905–917 (2007). doi:10.1080/08927020701392954

Li, D., Wang, F., Yang, Z., Zhao, Y.: How to identify dislocations in molecular dynamics simulations? Sci. China Phys. Mech. Astron. 57(12), 2177–2187 (2014). doi:10.1007/s11433-014-5617-8

Muhammad I., Fayyaz H., Muhammad R., Ahmad S.A.: Dynamic characteristics of nanoindentation in Ni: a molecular dynamics simulation study. Chin. Phys. B 21(11), 116201 (2012)

Liang Y., Wang Q., Yu N., Chen J., Zha F., Sun Y.: Study of dislocation nucleation mechanism in nanoindentation process. Nanosci. Nanotechnol. Lett. 5(5), 536–541 (2013)

Kim K.J., Yoon J.H., Cho M.H., Jang H.: Molecular dynamics simulation of dislocation behavior during nanoindentation on a bicrystal with a <i>Σ</i> = 5 (210) grain boundary. Mater. Lett. 60(28), 3367–3372 (2006)

Li J., Soh A.K.: Toughening of nanocrystalline materials through shear-coupled migration of grain boundaries. Scr. Mater. 69(4), 283–286 (2013). doi:10.1016/j.scriptamat.2013.04.014

Farkas D., Frøseth A., Van Swygenhoven H.: Grain boundary migration during room temperature deformation of nanocrystalline Ni. Scr. Mater. 55(8), 695–698 (2006). doi:10.1016/j.scriptamat.2006.06.032

Wan L., Wang S.: Shear response of the Σ9<110>{221} symmetric tilt grain boundary in fcc metals studied by atomistic simulation methods. Phys. Rev. B Condens. Matter 82(21), 214112 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nejadseyfi, O., Shamsborhan, M., Azimi, A. et al. The roles of crystallographic orientation, high-angle grain boundary, and indenter diameter during nano-indentation. Acta Mech 226, 3823–3829 (2015). https://doi.org/10.1007/s00707-015-1406-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-015-1406-3