Abstract

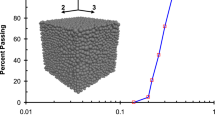

The theoretical need to recognize the link between the basic microstructure of nonlinear porous materials and their macroscopic mechanical behavior is continuously rising owing to the existing engineering applications. In this regard, a semi-analytical homogenization model is proposed to establish an overall, continuum-level constitutive law for nonlinear elastic materials containing prolate/oblate spheroidal voids undergoing finite axisymmetric deformations. The microgeometry of the porous materials is taken to be voided spheroid assemblage consisting of confocally voided spheroids of all sizes having the same orientation. Following a kinematically admissible deformation field for a confocally voided spheroid, which is the basic constituent of the microstructure, we make use of an energy-averaging procedure to obtain a constitutive relation between the macroscopic nominal stress and deformation gradient. In this work, both prolate and oblate voids are considered. As a numerical example, we study macroscopic nominal stress components for a hyperelastic porous material consisting of a neo-Hookean matrix and prolate/oblate voids subjected to 3-D and plane strain dilatational loadings. In this numerical study, the relation between the relevant microstructural variables (i.e., initial porosity and void aspect ratio) for a rather large range of applied stretch is put into evidence for two types of loading. Finally, a finite element (FE) simulation is presented, and the homogenization model is assessed through comparison of its predictions with the corresponding FE results. The illustrated agreement between the results demonstrates a good accuracy of the model up to rather large deformations.

Similar content being viewed by others

References

Nemat-Nasser S., Hori M.: Micromechanics: Overall Properties of Heterogeneous Solids. Elsevier, Amsterdam (1993)

Milton G.W.: The Theory of Composites. Cambridge University Press, Cambridge (2002)

Buryachenko V.: Micromechanics of Heterogeneous Materials. Springer, Berlin (2007)

Danielsson M., Parks D.M., Boyce M.C.: Constitutive modeling of porous hyperelastic materials. Mech. Mater. 36, 347–358 (2004)

Lopez-Pamies O., Ponte Castaneda P.: Homogenization-based constitutive models for porous elastomers and implications for macroscopic instabilities: II—results. J. Mech. Phys. Solids 55, 1702–1728 (2007)

Bucknall CB.: Toughened Plastics. Applied Science, London (1977)

Talbot D.R.S., Willis J.R.: Variational principles for inhomogeneous non-linear media. IMA J. Appl. Math. 35, 39–54 (1985)

Ponte Castaneda P.: Second-order homogenization estimates for nonlinear composites incorporating field fluctuations. I. Theory. J. Mech. Phys. Solids 50, 737–757 (2002)

Lopez-Pamies O., Ponte Castaneda P.: Homogenization-based constitutive models for porous elastomers and implications for macroscopic instabilities: I—analysis. J. Mech. Phys. Solids 55, 1677–1701 (2007)

Hashin Z.: The elastic moduli of heterogeneous materials. J. Appl. Mech. 29, 43–50 (1962)

Hashin, Z., Rosen, B.: The elastic moduli of fiber reinforced materials. J. Appl. Mech. 31, 223–32 (1964)

Hashin Z.: Large isotropic elastic deformation of composites and porous media. Int. J. Solids Struc. 21, 711–720 (1985)

Kakavas PA., Anifantis N.K.: Effective moduli of hyperelastic porous media at large deformation. Acta Mech. 160, 127–147 (2003)

deBotton G., Hariton I., Socolsky E.A.: Neo-Hookean fiber-reinforced composites in finite elasticity. J. Mech. Phys. Solids 54, 533–559 (2006)

deBotton, G., Hariton, I.: Out-of-plane shear deformation of a neo-hookean fiber composite. Phys. Lett. A 354, 156–60 (2006)

Avazmohammadi R., Naghdabadi R.: Strain energy-based homogenization of non-linear elastic particulate composites. Int. J. Eng. Sci. 47, 1038–1048 (2009)

Avazmohammadi R., Naghdabadi R., Weng G.J.: Finite anti-plane shear deformation of nonlinear composites reinforced by elliptic fibers. Mech. Mater. 41, 868–877 (2009)

Goudarzi, T., Lopez-Pamies, O.: Numerical modeling of the nonlinear elastic response of filled elastomers via composite-sphere assemblages. J. Appl. Mech. (2013) (in press)

Zhao Y.H., Tandon G.P., Weng G.J.: Elastic moduli for a class of porous materials. Acta. Mech. 76, 105–131 (1989)

Bouchart V., Brieu M., Kondo D., Nait Abdelaziz M.: Implementation and numerical verification of a non-linear homoge- nization method applied to hyperelastic composites. Comput. Mater. Sci. 43, 670–680 (2008)

Benveniste Y., Milton G.W.: New exact results for the effective electric, elastic, piezoelectric and other properties of composite ellipsoid assemblages. J. Mech. Phys. Solids 51, 1773–1813 (2003)

Gologanu M., Leblond J.-B., Devaux J.: Approximate models for ductile metals containing non-spherical voids-case of axisymmetric prolate ellipsoidal cavities. J. Mech. Phys. Solids. 41, 1723–1754 (1993)

Gologanu, M., Leblond, J.B., Devaux, J.: Approximate models for ductile metals containing nonspherical voids-case of axisymmetric oblate ellipsoidal cavities. J. Eng. Mater. Tech. Trans. ASME 116, 290–297 (1994)

Hou H., Abeyaratne R.: Cavitation in elastic and elastic–plastic solids. J. Mech. Phys. Solids 40, 571–592 (1992)

Hill R.: On constitutive macro-variables for heterogeneous solids at finite strain. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 326, 131–147 (1972)

Criscione J.C., Douglas A.S., Hunter W.C.: Physically based strain invariant set for materials exhibiting transversely isotropic behavior. J. Mech. Phys. Solids 49, 871–897 (2001)

Criscione J.C.: Rivlin’s representation formula is ill-conceived for the determination of response functions via biaxial testing. J. Elast. 70, 129–147 (2003)

Ogden R.W.: Nonlinear Elastic Deformations. Halsted Press, New York (1984)

Siruguet K., Leblond J.B.: Effect of void locking by inclusions upon the plastic behavior of porous ductile solids— I: theoretical modeling and numerical study of void growth. Int. J. Plast. 20, 225–254 (2004)

Li Y., Ramesh K.T.: Influence of particle volume fraction, shape, and aspect ratio on the behavior of particle-reinforced metal matrix–matrix composites at high rates of strain. Acta. Mater. 46, 5633–5646 (1998)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Avazmohammadi, R., Naghdabadi, R. Effective behavior of porous elastomers containing aligned spheroidal voids. Acta Mech 224, 1901–1915 (2013). https://doi.org/10.1007/s00707-013-0853-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-013-0853-y